Ansys Fluent: Create advanced physics models , generates accurate and reliable fluid simulation results —all in a customizable and intuitive space

Ansys Fluent unlocks new potentials for CFD analysis. A fluid simulation software with fast pre-processing and faster solve times to help you be the fastest to break into the market. Fluent’s industry leading features enable limitless innovation, while never making a compromise on accuracy. Ansys Fluent pushes the envelope of performance, sustainability, and productivity for computational fluids dynamics (CFD) simulations. This release includes significant GPU technology advancements, accurate hydrogen modeling from production to consumption, workflow, and automation improvements.

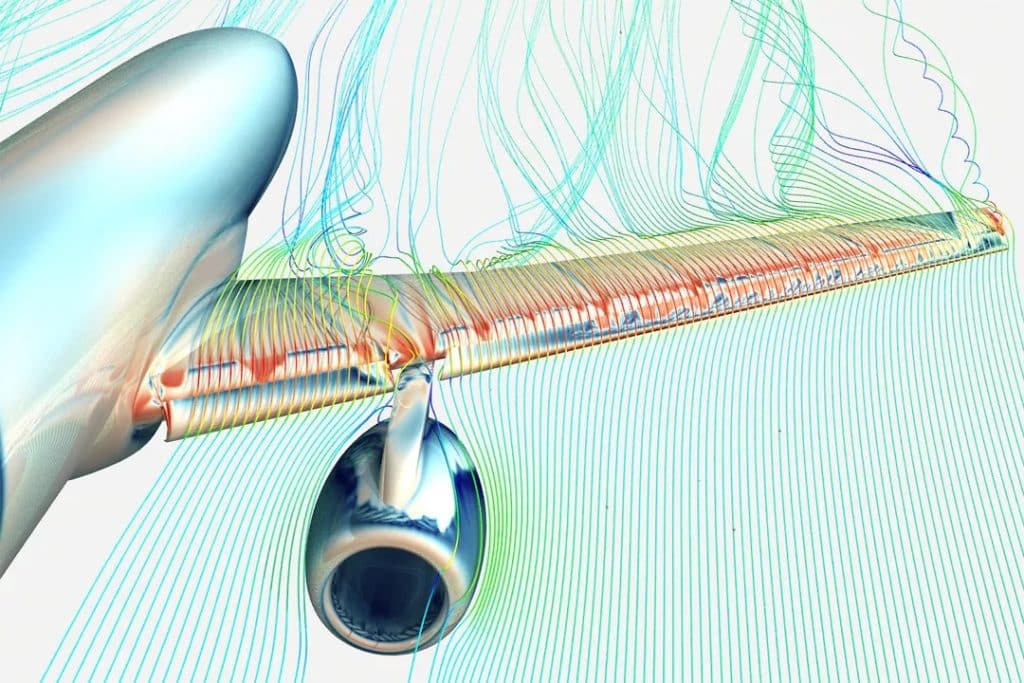

Hypersonic Speed Simulation Software

Ansys simulation tools are perfect solutions to examine all the challenges of hypersonic speed. As an aircraft begins to travel above Mach 1, fluids start to exhibit different physical behavior. Our multiphysics simulations enable users to capture the complex phenomena that occur, including strong shocks, plasma, ablation, structural deformation and chemical nonequilibrium. Shorten your development time and reduce testing efforts with industry-leading software that allows you to quickly tackle problems specific to hypersonic design.

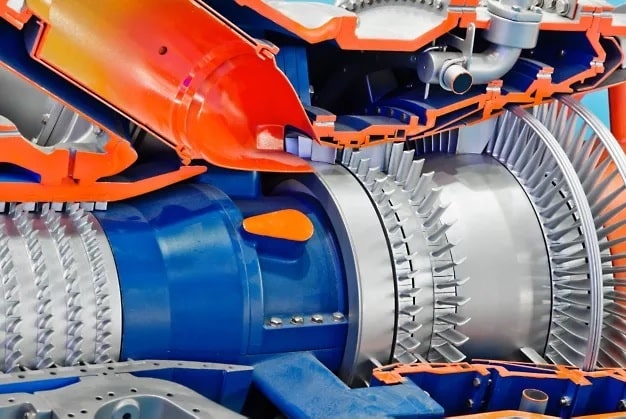

Gas Turbine Design, Modeling and Simulation

Leverage Ansys simulation to design the next generation of gas turbines. Optimize your gas turbine design process, minimize overdesign, reduce costs and accelerate time to market with our end-to-end solution. By using digital testing early in development, design changes can be made quickly and more affordably. Ansys can help you innovate and design safe, reliable and efficient gas turbines.

15% Reduction In Fuel Burn

Leverage simulations to tune the overall performance of your gas turbine by reducing specific fuel consumption.

30% Cost Reduction

Explore how efficient simulation solutions help to cut development costs and reliance on physical testing.

33% Design Cycle Time Reduction

Discover how simulation helps to streamline the design process and reduce cycle time and minimize overdesign.

9x-16x return on investment

Investing in simulation provides a competitive edge.

Designing gas turbines to meet performance and safety standards remains a challenging process. Ansys offers a best-in-class multiphysics simulation solution for all gas turbine modules from inlet to exhaust. The end-to-end solution helps engine manufacturers increase safety, performance and efficiency while reducing emissions, noise, weight and maintenance cost.

Gas turbine simulation is an integral part of the design process. Original equipment manufacturers (OEMs) demand robust, fast and accurate solutions to reach optimized designs the first time. Ansys offers a range of solutions including, but not limited to:

- Aerodynamic performance

- Combustion, acoustics and aerothermal

- Structural durability and reliability

- Foreign object damage, blade out and icing

- Additive manufacturing, digital twin and ROMs

- Process compression; Workflow Management

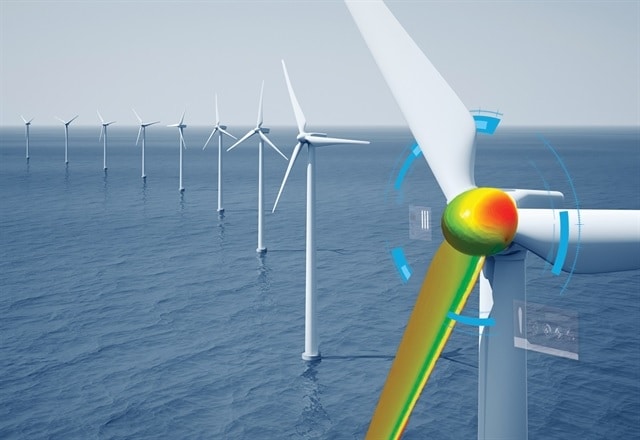

Wind Turbine Design, Location and Operational Optimization

The global energy mix continues to rebalance, demanding more efficient, larger wind turbines that can operate in harsher environments—both onshore and offshore. Ansys provides a comprehensive multiphysics, multiscale simulation solution for wind turbine engineering development, manufacturing and in-service operations.

As engineers devise new ways to capture renewable energy from the wind – from traditional large scale wind turbines to innovative turbines on high-rise buildings and artificial trees with energy generating mechanical leaves – Ansys’ comprehensive modeling and simulation solutions enable engineers to ensure their designs deliver maximum performance and efficiency.

Battery Design and Simulation

Advance your battery design and safety with rapid, accurate simulation. Electrochemistry can be used for age and life prediction. Battery thermal management and runaway can be simulated to ensure top performance and safety. A reduced order model (ROM) can be created by extracting key thermal characteristics to analyze temperature in seconds.

Ansys helps you advance battery designs while balancing safety, performance, size, cost and reliability to make you the market leader. Our multiphysics battery simulation solution helps bring together interdisciplinary expertise at different scales. With our help, you can reduce project costs by up to 30% and design cycle time by up to 50%.

Performance Modeling Solutions

Whether designing a battery for electric transportation or consumer products, every design choice requires complex decisions. Engineers can rapidly evaluate tradeoffs while minimizing reliance on arbitrary design rules and expensive, trial-and-error physical testing. Our accurate battery simulation gets the results you need from electrochemistry to electrode, cell, module, pack and system and the coupling of different physics.

Simulation for Battery Cell Production

Electrochemistry simulation supports from the manufacturing of the battery cell to predicting age and lifetime. Cell manufacturers are tasked with the challenging job of storing as much power as possible, while reducing size, weight and cost. Accurately simulating electrochemistry before the manufacturing process helps with materials property selection and electrode structure design.

Best-in-Class Battery Thermal Management

Batteries are extremely sensitive to temperature. Thermal management is critical to reduce temperature variations and to avoid thermal runaway. As a battery’s temperature increases, its rate of chemical reactions and performance can improve. However, at one point, a rise in temperature may cause permanent damage. Ansys delivers best-in-class thermal management simulation to produce a cost-effective cooling device and safe battery.

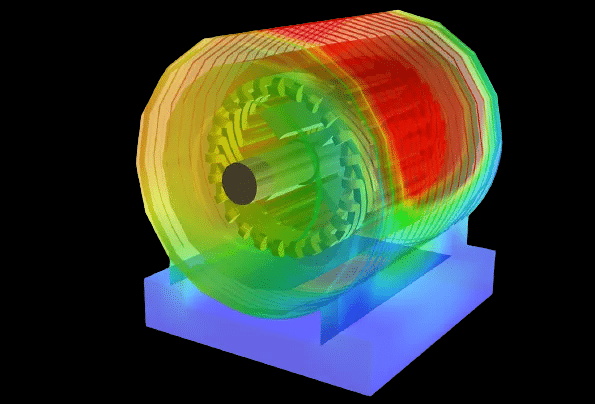

Electric Motor Design, Analysis and Verification

Ansys offers a complete workflow that progresses from concept design to detailed electromagnetics, thermal and mechanical analyses of the motor. Coupled electromagnetic-thermal-stress-and vibro-acoustics simulation of the motor using Ansys tools such as Ansys Fluent, Ansys Maxwell and Ansys sound results in a high-fidelity, accurate and robust design that is optimized for performance, cost and efficiency.

Turbulence Models

A wide range of turbulence models are available to choose the right model for your application. Fluent offers a wide range of turbulence models including the industry-leading Generalized k-ω (GEKO) model. GEKO is a revolutionary concept with tunable coefficients that can be adjusted to different flow regimes.

Simulate With a Range of Multiphase Flows

Ansys Fluent offers an extensive range of gas-liquid multiphase flow simulation capabilities spanning discrete phase modeling (DPM), volume of fluid (VoF) and Eulerian Multiphase. Critical to chemical, pharmaceutical and petrochemical processes, the effective design, scale up and operation of gas liquid process equipment systems delivers significant productivity and efficiency impact over the lifecycle of the equipment. Simulation enables you to ensure optimal performance gets replicated across scales of operation before expensive equipment is installed and commissioned.

Combustion Models

Accurate combustion models allow you to gain insight into system performance and flow phenomena. Assuring you have accurate combustion is critical for the precise mix of turbulence, chemistry and the interaction between them. Fluent offers accurate and validated reacting flow models for your combustion applications.

Fluid Structure Interaction

Accurately predict interactions between fluids and solids from pressure and/or thermal loads. Solve your fluid-structure interaction challenge to make sure your product is safe, reliable and optimized. Fluent can solve FSI problems standalone and couples with Ansys Mechanical for the most complex simulations.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae, ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Reactor Design & Combustion Engineering for Chemical Processing

Heat Transfer-Equipment Design and Analysis for Chemical Processing: Comprehensive CFD & Finite element method

Mixer Design and Analysis with FEA and CFD based-Simulation

Multiphase Simulation for Chemical Processing

Filtration System Design and Engineering for Chemical Processing with CFD & Finite Element Method

Chemical Processing Simulation and Design: Coupled CFD, FEA and 1D-System Modeling for Heat Transfer, Filtration & Mixer System , Reactor Design & Combustion Engineering

Oil, Gas and Petrochemical Industries

GREEN ENERGY: WIND TURBINE AND WIND FARM

Gas Turbine Combustion CFD Simulation: Detailed Chemistry

Fuel Injectors and Spray CFD Simulation

Electromagnetic Multiphysics

CFD Simulation of Reacting Flows and Combustion

CFD Simulation of Engine Exhaust Aftertreatment

1D/3D Coupled Simulation and Co-Simulation: Detailed Chemistry & Multiphase Flow Modeling with 1D Modeling

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Simulation of Plasma Based Devices: Microwave Plasma and RF Plasma Analysis with Coupling Particle in Cell (PIC), MHD, CFD and FEA Solvers

Finite Element Analysis of Durability and Fatigue Life

Multi-Phase Flows CFD Analysis

Turbomachinery Generative Design & Optimization

Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Race Car Aerodynamic Simulation and Optimization via CFD

Turbine, Pump & Compressor (Axial or Centrifugal)

Rotors Aerodynamic Simulation via Coupled FEA (MBD)/CFD Method: Aeroelastic Behavior Assessment

Drone Aerodynamic & Acoustic Simulation Based Design

Hydrodynamics & HydroAcoustics simulation for AIV (Acoustic Induced Vibration)

Ship Stability & Safety Analysis Including Hydrodynamics & Aerodynamics Effects

Cavitation in Propulsion Systems

Hydrodynamic Performance of Ship Hull: CFD Based Design

Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Hydroplaning (Aquaplaning) Simulation

Hydropower, Solar Power and Biomass

Structural Dynamics Integrity & Vibro-Acoustics Simulation for Marine & Shipbuilding Industry

CFD and FEA in Civil Engineering: Seismic Design, Earthquake, Tunnel, Dam, Concrete Structures and Geotechnical Multiphysics Simulation

Marine and Shipbuilding Industry: Finite Element and CFD Based Simulation and Design

In Silico Medical & Biomedical Device Testing: Finite Element & CFD Simulation and Design, Considering FDA & ASME V&V 40

FEA and CFD Simulation for Aerospace Structures: Aerodynamics, Acoustics, Fatigue and Vibration, Thermal Analysis, Crash & Impact