Ansys CFX: Turbomachinery CFD Software, Aeromechanics, Industry leading turbulence modeling and Nuclear Wall boiling

Ansys CFX is a computational fluid dynamics (CFD) software tool that allows you to design and optimize turbomachinery, including pumps, turbines, compressors, fans, and other rotating machinery. CFX is known for being the gold standard in accuracy for turbomachinery with extensive industry validation. CFX helps you improve your turbomachinery designs by improving efficiency, safety, and durability. Solve a variety of fluids-related problems with high levels of accuracy and unmatched speed: Blade design and optimization, Aeromechanics, Industry leading turbulence modeling, Nuclear Wall boiling, Advanced material modeling.

Gas Turbine Design, Modeling and Simulation

Leverage Ansys CFX simulation to design the next generation of gas turbines. Optimize your gas turbine design process, minimize overdesign, reduce costs and accelerate time to market with our end-to-end solution. By using digital testing early in development, design changes can be made quickly and more affordably. Ansys CFX can help you innovate and design safe, reliable and efficient gas turbines.

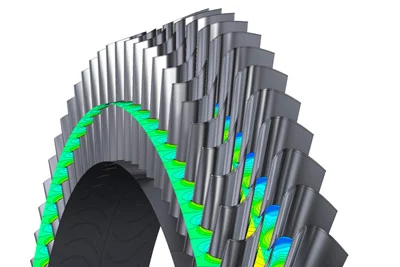

Rotating Machinery Simulation and Optimization

Ansys offers state-of-the-art software to help design a wide variety of rotating machinery equipment. Whether you are developing fans, pumps, compressors or turbines, Ansys simulation software allows you to quickly iterate and improve on designs. Simulation provides insight to key metrics prior to manufacturing and testing. It is a reliable method to increase efficiency and reduce development costs and time to market.

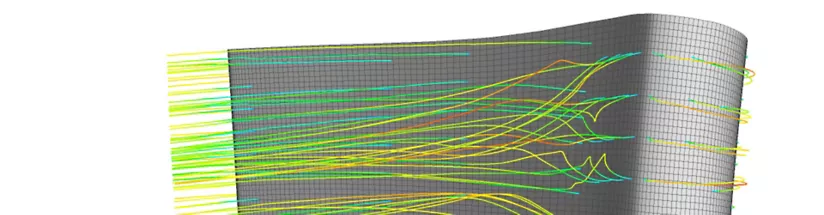

Blade Design and Optimization

Streamlined workflows with blade design integration to help optimize your design.

Streamline your workflow starting from our blade design tools or software partner offerings, from design to mesh to a robust result. Design toolsand optimization methods are integrated into our turbo workflows for the best design improvements.

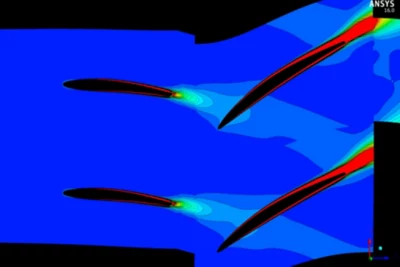

Aeromechanics

Improve safety of rotating components with accurate aeromechanical simulations.

Early aeromechanical simulations help improve safety and durability of rotating components. Transient blade row (TBR) methods are used to reduce geometry from a full-wheel to a single passage. Problems are solved with time marching or harmonic balance.

Turbulence Modeling

A wide range of turbulence models are available, allowing you to choose the best model for your application. CFX also includes the industry leading Generalized k-co (GEKO) model. GEKO is a revolutionary concept with tunable coefficients that can be adjusted to different flow regimes.

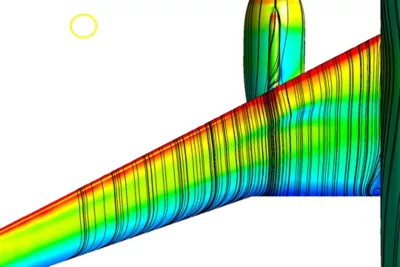

Subcooled Wall Boiling

Accurately model wall boiling and calculate the critical heat flux using validated models for bubble growth, phase change, drag and non-drag forces.

Advanced Material Modeling

Get the most accurate results with real gas and fluids properties

CFX’s advanced material modeling help generate the most accurate results. Real gas and fluid property tables can be created from the REFPROP database using adaptive methods to efficiently resolve changes in material properties (near critical point, for example). Liquid water and steam properties are selectable from the built-in IAPWS database.

Turbomachinery Generative Design & Optimization

Heat Transfer Simulations for Turbomachinery

Cavitation in Propulsion Systems

1D/3D Coupled Simulation and Co-Simulation: Detailed Chemistry & Multiphase Flow Modeling with 1D Modeling

Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Turbine, Pump & Compressor (Axial or Centrifugal)

Electromagnetic Multiphysics

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation

Aerodynamic Noise Simulation

Creep and Creep-Fatigue Interactions

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Finite Element Analysis of Durability and Fatigue Life

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Multi-objective Design & Optimization of Turbomachinery: Coupled CFD & FEA

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with CFD tools such as MSC Cradle, Ansys Fluent, StarCCM+ for flows simulation and FEA based Codes such as MSC Softwrae(Simufact, Digimat, Nastran, Marc, Actran Acoustic solver), ABAQUS, Ansys and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.