1D/3D Coupled Simulation and Co-Simulation: Detailed Chemistry & Multiphase Flow Modeling with 1D Modeling

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

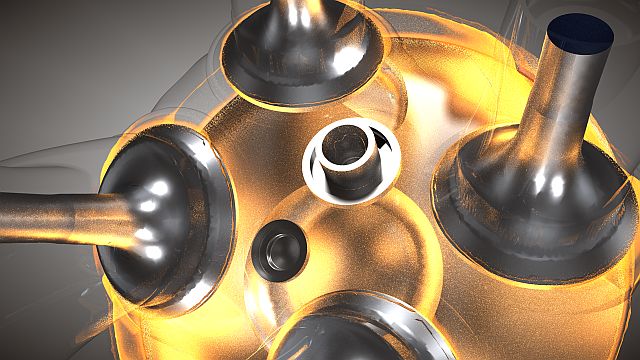

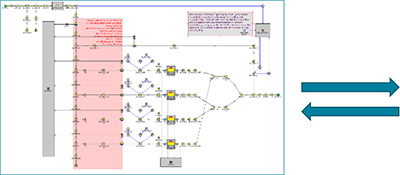

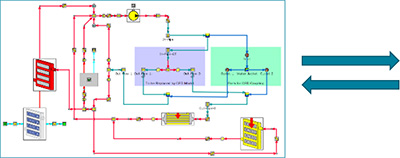

Enteknograte engineering team use advantage of CFD solver’s detailed chemistry, multiphase flow modeling, and other powerful features in coupling and co-simulation of CFD (Siemens Star-ccm+, AVL Fire, Ansys Fluent, Converge), 1D systems softwares (Matlab simulink, GT-Suite, Ricardo Wave allowing 1D/3D-coupled analyses to be performed effortlessly) and FEA software (Abaqus, Ansys, Nastran) for engine cylinder coupling, exhaust aftertreatment coupling, and fluid-structure interaction coupling simulation.

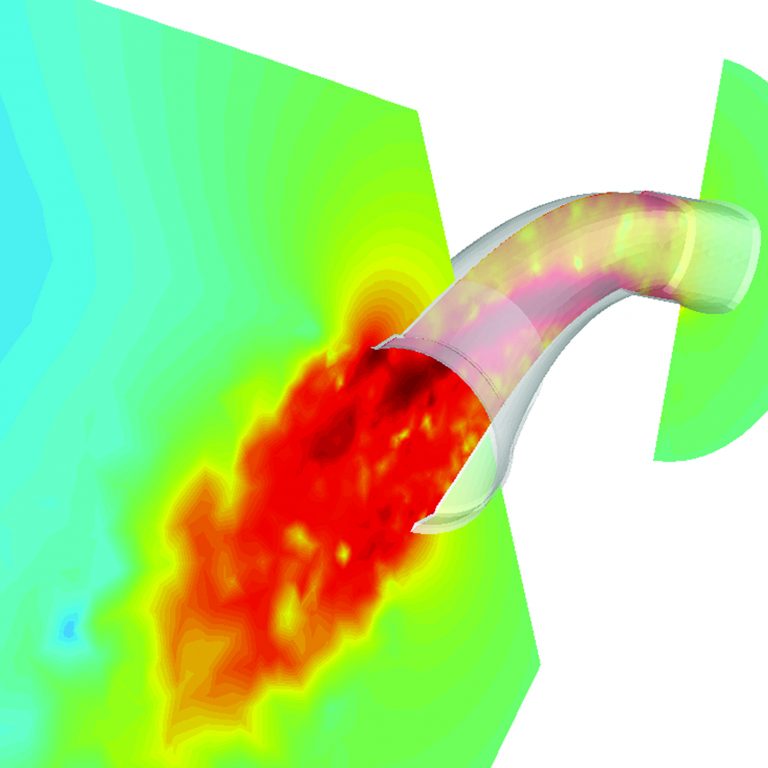

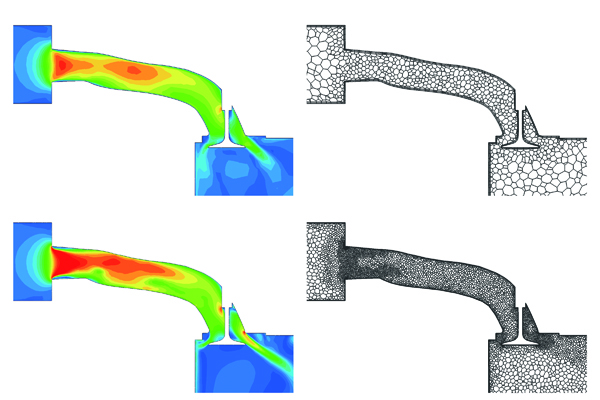

Using mentioned methods, enable us for development of intake runner systems and investigate the ways of improving mixing, and reducing cylinder-to-cylinder variations in air/fuel ratios and exhaust gas recirculation (EGR). The location of EGR pipes and their design can be determined and the dynamics of the intake system can be optimized.

This analysis approach can also be used on exhaust components. Exhaust runner lengths and catalyst cone designs can be investigated and lambda sensor locations can be determined. After-treatment simulations can also be performed looking at catalyst utilization, light-off potential and selective catalytic reduction (SCR) system design.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

By using Accurate reaction mechanisms that representing every class of reaction important for combustion analysis and combination of advanced computational fluid dynamics (CFD) combustion simulation tools such as Kiva, Ansys Fluent, Ansys Forte, AVL Fire, Converge CFD, Siemens Star-ccm+ , MSC Cradle and System Modeling software such as Matlab Simulink and GT-Suite enable Enteknograte engineering team to reduce chemistry analysis time by orders of magnitude, virtually eliminating the bottleneck that chemistry integration produces during the simulation process.

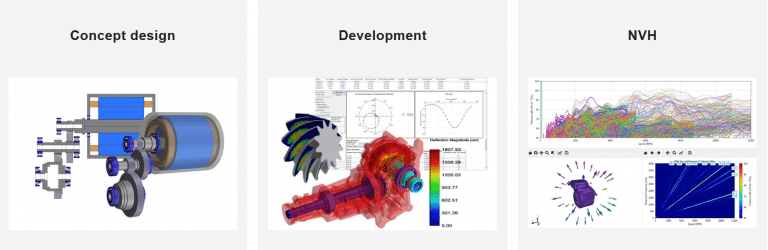

NVH based Design and Considerations in Reacting Flows and Combustion Systems

The challenge for the NVH specialists is to support the concept and design development process by reliable recommendations just-in-time prior concept or design freeze. Enteknograte’s specialists particularly use advanced methodologies for NVH simulation and optimization:

- FEA based Powertrain

- Structural Optimization

- Optimization of Engine Dynamics based on MBD ( Multi-Body Dynamics Simulation)

- Concurrent optimization of combustion efficiency with NVH considerations

- Vehicle Interior Noise Simulation based on measurement and CAE

- Vehicle Exterior Noise Simulation with couple use of CFD and FEA solvers

- Objective Analysis of Sound Quality

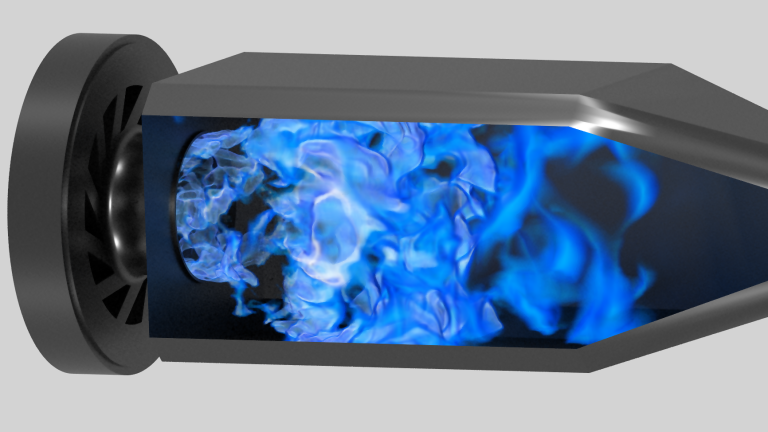

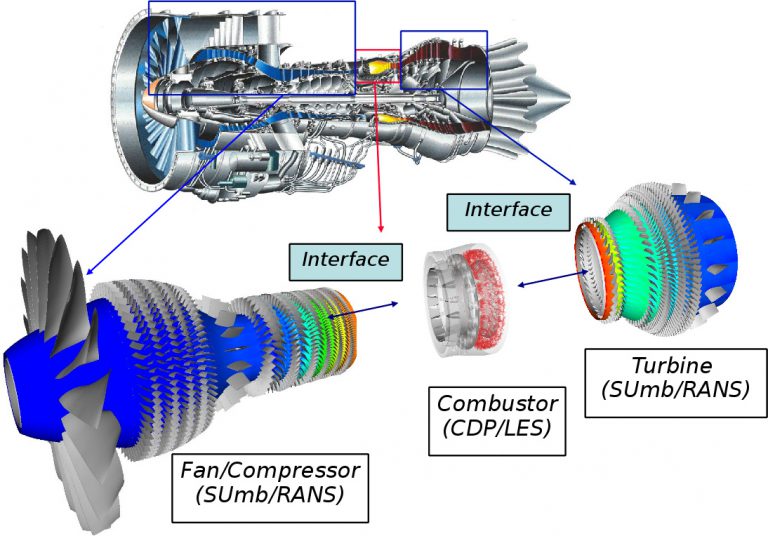

Gas Turbine Combustion CFD Simulation: Detailed Chemistry

AVL Fire, Siemens Star-ccm+, Ansys Fluent and Converge

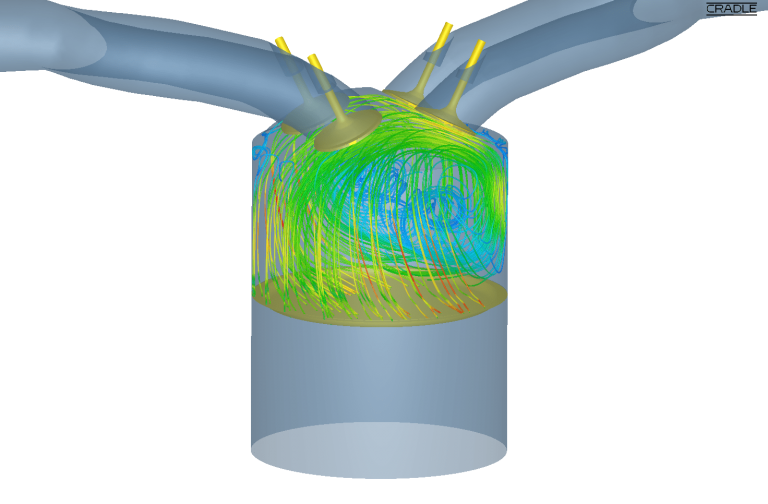

Gas turbine combustion can be a challenge to achieve accurate and reliable CFD simulation results. Computational efficiency requires appropriate mesh resolution and turbulence, spray, combustion, and emissions models that provide an appropriate level of detail. With using advanced and specilized CFD tools such as AVL Fire, Siemens Star-ccm+, Ansys Fluent and Converge, Enteknograte engineers can accurately predict important kinetically limited gas turbine phenomena such as ignition, flashback, and lean blow off. In addition, we can investigate the combined effects of chemistry and turbulence and optimize combustor performance parameters.

Read more... Fuel Injectors and Spray CFD Simulation

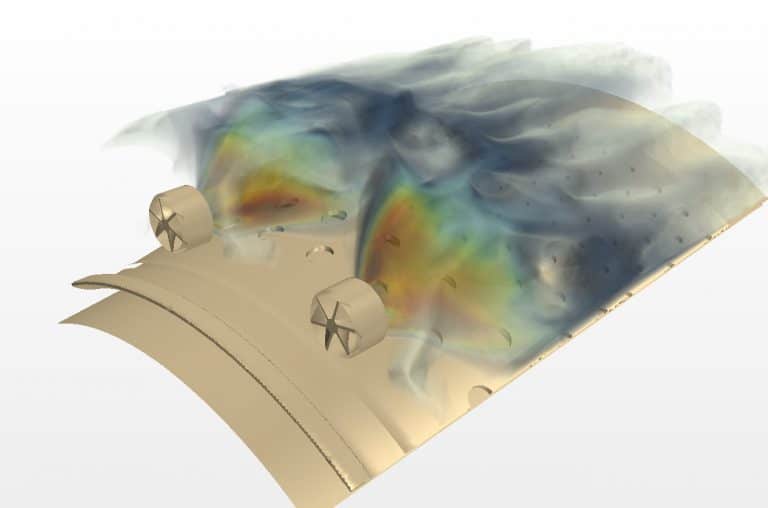

CFD software such as MSC Cradle, AVL Fire, Siemens Star-ccm+, Ansys Fluent and Converge is well equipped to simulate fuel injectors and spray processes including liquid atomization, drop breakup, collision and coalescence, turbulent dispersion, spray cavitation, drop-wall interaction, and drop evaporation.

Read more... Spray, Combustion, Emissions, Shaft and Gear Systems, Acoustic Enclosures

Gas turbine combustion is a complex process, and it can be a challenge to achieve accurate and reliable Finite Element and CFD simulation results at a reasonable computational cost. Computational efficiency requires appropriate mesh resolution and turbulence, spray, combustion, and emissions models in CFD tools such as AVL Fire, Siemens Star-ccm+, Ansys Fluent and Converge that provide an appropriate level of detail. It needs adavnced combination of Finite Element and Acoustic Solvers to capture real-world vibration and structural performance with FEA tools such as Abaqus, Ansys and LS-Dyna and Acoustic solver such as MSC Actran and ESI VA-ONE.

Read more... CFD Simulation of Reacting Flows and Combustion

Engine & Gas Turbine, Fuel Injector & Spray, Exhaust Aftertreatment with Detailed Chemistry

Knowledge of the underlying combustion chemistry and physics enables designers of gas turbines, boilers and internal combustion engines to increase energy efficiency and fuel flexibility, while reducing emissions. Combustion System couples multiphysics simulations incorporating accurate physical models with an advanced chemistry solver to provide a complete end-to-end combustion chemistry simulation capability to optimize products that involve reacting flow.

Read more... CFD Simulation of Engine Exhaust Aftertreatment

Aftertreatment systems are a critical component to ensure emissions from engines and power generation equipment comply with environmental standards. CFD (computational fluid dynamics) simulations can be used as part of a rapid prototyping process to design systems that reduce NOx, CO, and particulate matter emissions with minimal efficiency and maintenance costs. Two of the main challenges in aftertreatment system design are maximizing the uniformity of flows upstream of catalysts and eliminating areas at risk for urea deposition.

Read more... Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Noise and vibration analysis is becoming increasingly important in virtually every industry. The need to reduce noise and vibration can arise because of government legislation, new lightweight constructions, use of lower cost materials, fatigue failure or increased competitive pressure. With deep knowledge in FEA, CFD and Acoustic simulation, advanced Acoustic solvers and numerical methods used by Enteknograte engineers to solve acoustics, vibro-acoustics, and aero-acoustics problems in automotive manufacturers and suppliers, aerospace companies, shipbuilding industries and consumer product manufacturers.

Read more... Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Machine learning is a method of data analysis that automates analytical model building. It is a branch of Artificial Intelligence based on the idea that systems can learn from data, identify patterns and make decisions with minimal human intervention. With Artificial Intelligence (AI) applications in CAE, that is Mechanical Engineering and FEA and CFD Simulations as design tools, our CAE engineers evaluate the possible changes (and limits) coming from Machine learning, whether Deep Learning (DL), or Support vector machine (SVM) or even Genetic algorithms to specify definitive influence in some optimization problems and the solution of complex systems.

Read more... Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

We analyze system-level thermal management of vehicle component, including underhood, underbody and brake systems, and design for heat shields, electronics cooling, HVAC, hybrid systems and human thermal comfort. Our Finite Element (LS-Dyna, Ansys, Abaqus) and CFD simulation (Siemens Start-ccm+, Ansys Fluent , Ansys CFX and OpenFoam) for heat transfer analysis, thermal management, and virtual test process can save time and money in the design and development process, while also improving the thermal comfort and overall quality of the final product.

Read more... Finite Element Analysis of Durability and Fatigue Life

Vibration Fatigue, Creep, Welded Structures Fatigue, Elastomer and Composite Fatigue with Ansys Ncode, Simulia FE-Safe, MSC CAEFatigue, FEMFAT

Durability often dominates development agendas, and empirical evaluation is by its nature time-consuming and costly. Simulation provides a strategic approach to managing risk and cost by enabling design concepts or design changes to be studied before investment in physical evaluation. The industry-leading fatigue Simulation technology such as Simulia FE-SAFE, Ansys Ncode Design Life and FEMFAT used to calculate fatigue life of multiaxial, welds, short-fibre composite, vibration, crack growth, thermo-mechanical fatigue.

Read more... Multi-Phase Flows CFD Analysis

Multi-Phases flows involve combinations of solids, liquids and gases which interact. Computational Fluid Dynamics (CFD) is used to accurately predict the simultaneous interaction of more than one combination of phases that can be gases, solids or fluids. Typical applications involve sprays, solid particulate transport, boiling, cavitation, state-changes, free surface flows, dispersed multiphase flows, buoyancy problems and mixed species flows. For example, the risks from flow or process-induced vibration excitation of pipework are widely acknowledged in onshore process plants, offshore topsides and subsea facilities.

Read more... Previous

Next