Multi-Phase Flows CFD Analysis

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

Multi-Phases flows involve combinations of solids, liquids and gases which interact. Computational Fluid Dynamics (CFD) is used to accurately predict the simultaneous interaction of more than one combination of phases that can be gases, solids or fluids. Typical applications involve sprays, solid particulate transport, boiling, cavitation, state-changes, free surface flows, dispersed multiphase flows, buoyancy problems and mixed species flows. For example, the risks from flow or process-induced vibration excitation of pipework are widely acknowledged in onshore process plants, offshore topsides and subsea facilities.

Multiphase flow is particularly of concern because forces can vary considerably with flow regimes, and so relatively small changes in the gas to oil ratio can result in significant changes in dynamic force levels. These forces can be relatively broadband in nature and can therefore excite a range of structural modes.

Enteknograte Engineering provides all forms of multi-phase flow analyses ranging from simple particle tracking calculations for industrial applications through to comprehensive design and optimisation of spray equipment and fluid jets. Enteknograte engineering team quickly evaluate alternative product and process designs to increase efficiency, reliability, safety and durability in a competitive, time-critical environment.

We Use CFD tools such as MSC Cradle, Ansys Fluent, Siemens Star-ccm+ and OpenFoam, and FEA Tools such as Abaqus, LS-DYNA and MSC Nastran with combination of very experienced engineers to help our customers in:

Fluid Spray Design and Optimization

CFD Simulation of sand erosion in a pipe carrying a multiphase mixture of oil and gas

Particulate Tracking and Concentration

Improving internal combustion engine emissions and fuel economy performance and with Design and Optimization Reacting Flows and Fuel Injection system

Simulating Mixing Tank, Mixed Species and Bioreactor Performance

Analysis the behavior of moored and/or connected systems, complex offshore, naval and marine structure subject to nonlinear oceanic/sea waves including Free Surface Flows

Simulation of water-landing scenarios Unmanned aerial vehicles (UAVs) with coupled use of CFD and FEA to analysis of probabilistic damage and real world performance prediction

CFD simulation of cavitation and its transient effect on structural integrity and Fatigue life coupled with FE

Multiphase Flows types and application

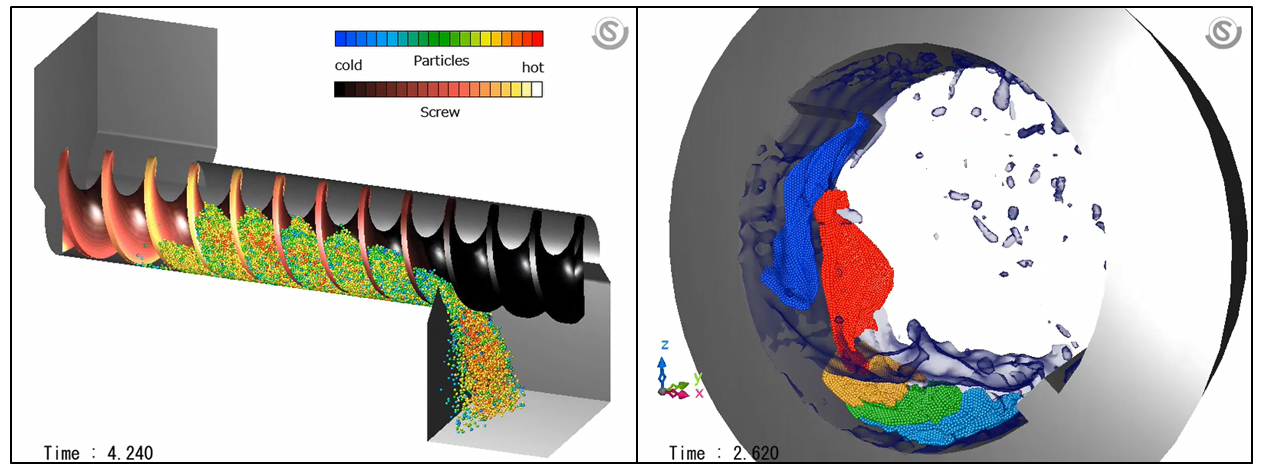

Our Engineers account the interactions between liquids, solids and gases. Each of these varied multiphase challenges requires a different modeling approach with Euler-Euler such as VOF or Euler-Lagrange method such as using Discrete Element Method to capture immersed particles interaction.

Gas-liquid and liquid-liquid flows

| Engineering challenge: | Dispersed Bubbly Flow | Dispersed Droplet Flow | Mixed or Transitional Flow | Separated Flow |

| Description: | Flow of bubbles in a continuous liquid. | Flow of liquid droplets in a gas or immiscible liquid. | Flows like slug, churnand annular whichinclude bothdispersed and separated elements. | Immiscible fluids separated by a clearly defined interface. |

| Application: | Absorbers, aeration, air lift pumps, cavitation, evaporators, flotation, and scrubbers. | Spays, absorbers, atomizers, combustors, cryogenic pumping, dryers, evaporation, gas cooling, and scrubbers. | Large bubble motion in pipes or tanks, slug catcher. | Sloshing in fuel tanks and offshore separator devices, wave motion simulation, boiling, condensation, container filling, centrifuges. |

Gas-solid flows

| Engineering challenge: | Particle-laden Flow | Pneumatic Transport | Fluidized Bed |

| Description: | Flow of discrete particles in a continuous gas. | Dry bulk materials move through a pipe by air or gas pressure. | Gas rising through a bed of particles forms a fluid-solid mixture that exhibits fluid-like properties. |

| Application: | Cyclone separators, air classifiers, dust collectors, and dust-laden environmental flows. | Transport of cement, grains, and metal powders. | Fluidized bed reactors and circulating fluidized beds used in chemical processes and coal combustion. |

Liquid-solid flows

| Engineering challenge: | Slurry Flows | Sedimentation |

| Description: | Movement of a liquid carrying dispersed solid particles. | Suspended particles settle out from the fluid and come to rest against a barrier. |

| Application: | Slurry transport, hydrotransport and mineral processing. | Mineral and waste processing. |

Particle Flows

| Engineering challenge: | Particle Flows | Three-Phase Flows |

| Description: | Flow of interacting particulates where there is negligible interaction with surrounding gas or liquid. | Gas, liquid and solid in combination of any flow regimes. |

| Application: | Conveyors, hoppers, filling. | Deep well, evaporator, gas-oil-water separator, two-phase fluidized bed with solid catalysts. |

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with CFD tools such as MSC Cradle, Ansys Fluent, StarCCM+ for flows simulation and FEA based Codes such as MSC Softwrae(Simufact, Digimat, Nastran, Marc, Actran Acoustic solver), ABAQUS, Ansys and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Reactor Design & Combustion Engineering for Chemical Processing

AVL Fire, Siemens Star-ccm+, Ansys Fluent and Converge

Our engineering simulation for reactor design including CFD for chemical reactor design, FEA structural and thermal analysis and instrumentation and control software used for design and analysis of chemical reactors enable our reaction engineers to answer what-if questions as they design and enhance reactors performance, energy usage, reactor yield and product uniformity.

Read more... Heat Transfer-Equipment Design and Analysis for Chemical Processing: Comprehensive CFD & Finite element method

Heat transmission by conduction, convection and radiation in laminar or turbulent flows for fluids, such as steam, thermal liquids, liquid metals and non-Newtonian fluids, can be design and analyze and new concept can be developed using engineering simulation for heat generation and heat transfer equipment. Using these solutions our engineers can identify hot spots, associated thermal stresses, equipment design and process efficiencies, and other issues that affect system performance.

Read more... Mixer Design and Analysis with FEA and CFD based-Simulation

In the chemical industry, proper reactor design is crucial because this is where both mixing and reaction occur. Mixing can be defined as an operation which reduces the degree of nonuniformity of all properties of a system, single or multiphase with one or many components. For a mixing sensitive reaction, the rate of mixing affects both the yield and selectivity of the reaction. Numerical flow simulations with CFD provide important insights into the flow processes of the entire system vessel agitator and the associated component.

Read more... Multiphase Simulation for Chemical Processing

Using a variety of advanced modeling techniques to study both continuous and particulate phases,with combination of Finite element method(FEA), DEM and CFD, we can handle simulation of particle included systems and their properties including following parameters: Particle flows,

Cohesion,

Material wear,

Particle size distribution,

Particle mechanics,

Surface and morphology,

Particle–particle interaction,

Turbulence and dispersion,

Geometry effects,

Erosion,

Particle attrition,

Homogeneous and hydrogenous reactions,

Particle flows,

Electrostatic effects.

Read more... Filtration System Design and Engineering for Chemical Processing with CFD & Finite Element Method

CFD for separation and filtration includes modeling of transport of solid particle are used by diverse set of customers to understand and reduce erosion in solid separation and extraction devices. Enteknograte’s engineering simulation team has experience in using FEA and CFD for separation and filtration systems, give clients a clearer understanding of filtration optimization through in-depth studies of filter media, particle deposition and caking, pressure drop, throughput, back flushing, and mechanical design.

Read more... Chemical Processing Simulation and Design: Coupled CFD, FEA and 1D-System Modeling for Heat Transfer, Filtration & Mixer System , Reactor Design & Combustion Engineering

Enteknograte's engineering team CFD and FEA solutions for the Materials & Chemical Processing is helping companies to significant engineering improvement from equipment and processes to chemical and petrochemical refining to glass and metals manufacturing - forming and casting -. Enteknograte's engineering team solution includes CFD for chemical process Industry, FEA for process industry and expand to cover electromagnetic and system design engineering concerns.

Read more... Oil, Gas and Petrochemical Industries

With combination of deep knowledge and experience in FEA and CFD and sophisticated simulation tools, Enteknograte engineers can solve any problem with any level of complexity in Oil, Gas and Petrochemical Industries: Drilling, Cementing/Mudflow in Casings, Offshore Structures Wind and Wave Loading, Offshore Structures and Hydrodynamics, Gas Dispersion, Environmental Pollution Dispersion, Blast Prevention, LNG Plant Site Selection Operation and Design,

Read more... Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Transient Resistance, Propulsion, Sea-Keeping and Maneuvering Simulation, Cavitation, Vibration and Fatigue

Hydrodynamics is a common application of CFD and a main core of Enteknograte expertise for ship, boat, yacht, marine and offshore structures simulation based design. Coupling Hydrodynamic CFD Simulation in Ansys Fluent, Siemens Star-ccm+ and MSC Cradle with structural finite element solver such as Abaqus and Ansys, enable us to Simulate most complicated industrial problem such as Cavitation, Vibration and Fatigue induced by hydrodynamics fluctuation, Transient Resistance, Propulsion, Sea-Keeping and Maneuvering Simulation, considering two way FSI (Fluid Structure Interaction) coupling technology.

Read more... Gas Turbine Combustion CFD Simulation: Detailed Chemistry

AVL Fire, Siemens Star-ccm+, Ansys Fluent and Converge

Gas turbine combustion can be a challenge to achieve accurate and reliable CFD simulation results. Computational efficiency requires appropriate mesh resolution and turbulence, spray, combustion, and emissions models that provide an appropriate level of detail. With using advanced and specilized CFD tools such as AVL Fire, Siemens Star-ccm+, Ansys Fluent and Converge, Enteknograte engineers can accurately predict important kinetically limited gas turbine phenomena such as ignition, flashback, and lean blow off. In addition, we can investigate the combined effects of chemistry and turbulence and optimize combustor performance parameters.

Read more... Fuel Injectors and Spray CFD Simulation

CFD software such as MSC Cradle, AVL Fire, Siemens Star-ccm+, Ansys Fluent and Converge is well equipped to simulate fuel injectors and spray processes including liquid atomization, drop breakup, collision and coalescence, turbulent dispersion, spray cavitation, drop-wall interaction, and drop evaporation.

Read more... Electromagnetic Multiphysics

Enteknograte Finite Element Electromagnetic Field simulation solution which uses the highly accurate finite element solvers and methods such as Ansys Maxwell, Simulia Opera, Simulia CST, JMAG, Cedrat FLUX, Siemens MAGNET and COMSOL to solve static, frequency-domain, and time-varying electromagnetic and electric fields includes a wide range of solution types for a complete design flow for your electromagnetic and electromechanical devices in different industries.

Read more... CFD Simulation of Reacting Flows and Combustion

Engine & Gas Turbine, Fuel Injector & Spray, Exhaust Aftertreatment with Detailed Chemistry

Knowledge of the underlying combustion chemistry and physics enables designers of gas turbines, boilers and internal combustion engines to increase energy efficiency and fuel flexibility, while reducing emissions. Combustion System couples multiphysics simulations incorporating accurate physical models with an advanced chemistry solver to provide a complete end-to-end combustion chemistry simulation capability to optimize products that involve reacting flow.

Read more... CFD Simulation of Engine Exhaust Aftertreatment

Aftertreatment systems are a critical component to ensure emissions from engines and power generation equipment comply with environmental standards. CFD (computational fluid dynamics) simulations can be used as part of a rapid prototyping process to design systems that reduce NOx, CO, and particulate matter emissions with minimal efficiency and maintenance costs. Two of the main challenges in aftertreatment system design are maximizing the uniformity of flows upstream of catalysts and eliminating areas at risk for urea deposition.

Read more... 1D/3D Coupled Simulation and Co-Simulation: Detailed Chemistry & Multiphase Flow Modeling with 1D Modeling

Enteknograte engineering team use advantage of CFD solver’s detailed chemistry, multiphase flow modeling, and other powerful features in coupling and co-simulation of CFD (Siemens Star-ccm+, AVL Fire, Ansys Fluent, Converge), 1D systems softwares (Matlab simulink, GT-Suite, Ricardo Wave allowing 1D/3D-coupled analyses to be performed effortlessly) and FEA software (Abaqus, Ansys, Nastran) for engine cylinder coupling, exhaust aftertreatment coupling, and fluid-structure interaction coupling simulation.

Read more... Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Machine learning is a method of data analysis that automates analytical model building. It is a branch of Artificial Intelligence based on the idea that systems can learn from data, identify patterns and make decisions with minimal human intervention. With Artificial Intelligence (AI) applications in CAE, that is Mechanical Engineering and FEA and CFD Simulations as design tools, our CAE engineers evaluate the possible changes (and limits) coming from Machine learning, whether Deep Learning (DL), or Support vector machine (SVM) or even Genetic algorithms to specify definitive influence in some optimization problems and the solution of complex systems.

Read more... Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

We analyze system-level thermal management of vehicle component, including underhood, underbody and brake systems, and design for heat shields, electronics cooling, HVAC, hybrid systems and human thermal comfort. Our Finite Element (LS-Dyna, Ansys, Abaqus) and CFD simulation (Siemens Start-ccm+, Ansys Fluent , Ansys CFX and OpenFoam) for heat transfer analysis, thermal management, and virtual test process can save time and money in the design and development process, while also improving the thermal comfort and overall quality of the final product.

Read more... Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Noise and vibration analysis is becoming increasingly important in virtually every industry. The need to reduce noise and vibration can arise because of government legislation, new lightweight constructions, use of lower cost materials, fatigue failure or increased competitive pressure. With deep knowledge in FEA, CFD and Acoustic simulation, advanced Acoustic solvers and numerical methods used by Enteknograte engineers to solve acoustics, vibro-acoustics, and aero-acoustics problems in automotive manufacturers and suppliers, aerospace companies, shipbuilding industries and consumer product manufacturers.

Read more... Simulation of Plasma Based Devices: Microwave Plasma and RF Plasma Analysis with Coupling Particle in Cell (PIC), MHD, CFD and FEA Solvers

Charged particles and their non-linear discharge characteristics have been especially difficult to model and simulate accurately. We provide consulting services for the modeling and simulation of plasma and other flow systems. Our consulting services utilize our specialized domain expertise in plasma, reactive flows and surface chemistry mechanism development and integration with multi-dimensional flow and plasma systems.

Read more... Hydrodynamics & HydroAcoustics simulation for AIV (Acoustic Induced Vibration)

The pressure reduction process induces turbulent pressure fluctuations in the flowing medium, which in turn excites the downstream pipe wall, causing stresses and potentially fatigue failure. The intensity of vibration tends to increase with mass flow rate, velocity, and pressure loss. AIV (Acoustic Induced Vibration) failures are known to occur preferentially at non-axisymmetric discontinuities in the downstream piping, such as at small-bore branches and their welded supports.

Read more... Ship Stability & Safety Analysis Including Hydrodynamics & Aerodynamics Effects

Operability limits can also be of more functional nature, e.g. holding a vessel steady against an offshore windmill foundation, or launching and recovering a dinghy safely onboard in seaway. Many issues related to dynamic stability of the vessel in waves, e.g. steerability of high speed marine vehicle in waves or the dynamic stability of a vessel against excessive heeling in extreme sea states: ship motions and accelerations Simulation, shipping of green water analysis, slamming impacts simulation, sloshing simulation, steerability in waves analysis, DP -capability simulation.

Read more... Cavitation in Propulsion Systems

CFD Analysis of Propulsion Systems and Cavitation for Marine and Shipbuilding Industry

For water pumps, marine propellers, and other equipment involving hydrofoils, cavitation can cause problems such as vibration, increased hydrodynamic drag, pressure pulsation, noise, and erosion on solid surfaces. Most of these problems are related to the transient behavior of cavitation structures. To better understand these phenomena, unsteady 3D simulations Modeling Cavitation of cavitating flow around single hydrofoils are often performed and the results are compared to experiments.

Read more... Hydrodynamic Performance of Ship Hull: CFD Based Design

A typical project for hydrodynamic hull optimization may include: Establishing a close dialog between Enteknograte and the Client;

Defining a realistic operating profile;

Discussing and combining Enteknograte ’s design ideas with the client’s design philosophy to obtain an optimal hull in both a hydrodynamic and building perspective;

Optimizing the hull forebody based on the operating profile;

Optimizing the hull aftbody to improve the propulsive efficiency, including consideration on propeller and machinery configuration;

Assessing the Energy Efficient Design Index.

Read more... In Silico Medical & Biomedical Device Testing: Finite Element & CFD Simulation and Design, Considering FDA & ASME V&V 40

Enteknograte Biomedical Engineers use FEA and CFD for simulating: Orthopedic products, Medical fasteners, Ocular modeling, Soft tissue simulation, Packaging, Electronic systems, Virtual biomechanics, Knee replacement, Human modeling, Soft tissue and joint modeling, Hospital equipment, Laser bonding, Ablation catheters, Dental implants, Mechanical connectors, Prosthetics, Pacemakers, Vascular implants, Defibrillators, Heart valve replacements.

Read more... Hydroplaning (Aquaplaning) Simulation

It is important to gain insights on the interaction of a tire with a film of water in order to diagnose the onset of hydroplaning and minimize the tire’s propensity to hydroplane. A coupled Eulerian-Lagrangian methodology, using a multi-material Finite Element formulation within advanced FEA software, is used to analyze the interaction of a tire with the water film. The effect of various parameters on the onset of hydroplaning are investigated using the methodology.

Read more... Hydropower, Solar Power and Biomass

As move to a more sustainable energy future, Hydro Power, Solar Power, Biomass and other renewable sources will play a key role in reducing our energy footprint and ensuring supply is sufficient for a modernizing population. Enteknograte’s simulation and optimization consultants support this growing industry. Our core competencies include turbine vortex simulation and prediction, acoustic interpretation and assessment, solar farm siting, composite blade analysis and optimization, and transmission dynamics simulation and optimization.

Read more... Structural Dynamics Integrity & Vibro-Acoustics Simulation for Marine & Shipbuilding Industry

CFD, Finite Element Method (FEM), Statistical energy analysis (SEA) & Boundary element method (BEM)

Structural-borne noise and vibration need to be minimized for passenger comfort and reduced environmental impact. Our full suite of vibro-acoustics simulation, and optimization tools ensures that we can minimize the structural dynamic impact of your vessel and its components early in the design phase. From large cruise ships to yachts, from frigates to submarines, many design challenges shall be addressed in the design phases of marine applications. If on the one hand the exterior noise, due to propellers, hull radiation or muffler, has to be limited for discretion or environmental reasons; on the other hand, interior noise is of concern for crew and passengers' comfort.

Read more... CFD and FEA in Civil Engineering: Seismic Design, Earthquake, Tunnel, Dam, Concrete Structures and Geotechnical Multiphysics Simulation

Enteknograte, offer a wide range of consulting services based on many years of experience using FEA and CFD: Coupled/Multiphysics problems: mechanics of porous media, spalling of concrete, freezing of ground and young hardening concrete Borehole stability problems Constitutive modeling of concrete Settlement damage on concrete and masonry constructions Pipelines, Earthquake analysis, Tunnel, Dam and Geotechnical Multiphysics Simulation.

Read more... Marine and Shipbuilding Industry: Finite Element and CFD Based Simulation and Design

Our experience in Marine and Shipbuilding Industry include: Fatigue assessment studies, Modal and vibration analyses, Seakeeping and seaworthiness assessment, Maneuvering studies, Simulation and evaluation of systems, Damage surveys and investigations, Tie-down structural calculations and approval, Collision Investigation, modeling and analysis, Optimizing the Hydrodynamic Performance of Hull, Cavitation, Marine Vibro-Acoustic, Dynamic Integrity.

Read more... Previous

Next