CFD Analysis of Propulsion Systems and Cavitation for Marine and Shipbuilding Industry

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

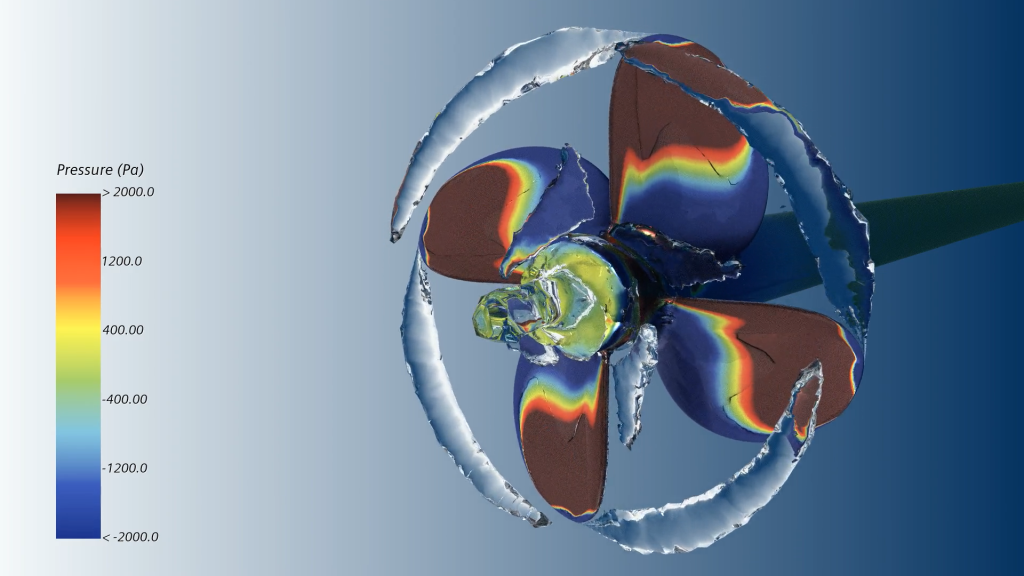

Achieving an optimal propulsion system early in the design phase ensures the vessel meets contract requirements while improving sea-going capacity and reducing vessel fuel consumption. Our solutions create a propeller digital twin early in the design phase, giving understanding of propulsion effects at full scale. From propeller in isolation to sub-systems to full system performance, design an optimal, innovative propulsion system that meets contractual and regulatory obligations at a lower cost.

Use our Propulsion Systems and Cavitation solutions to:

- Predict propeller performance, including the effects of cavitation and erosion.

- Optimize propeller designs for required operational efficiency.

- Simulate self-propulsion and analyze design-critical operating conditions.

- Improve existing fleet efficiency via energy saving devices and other refit options.

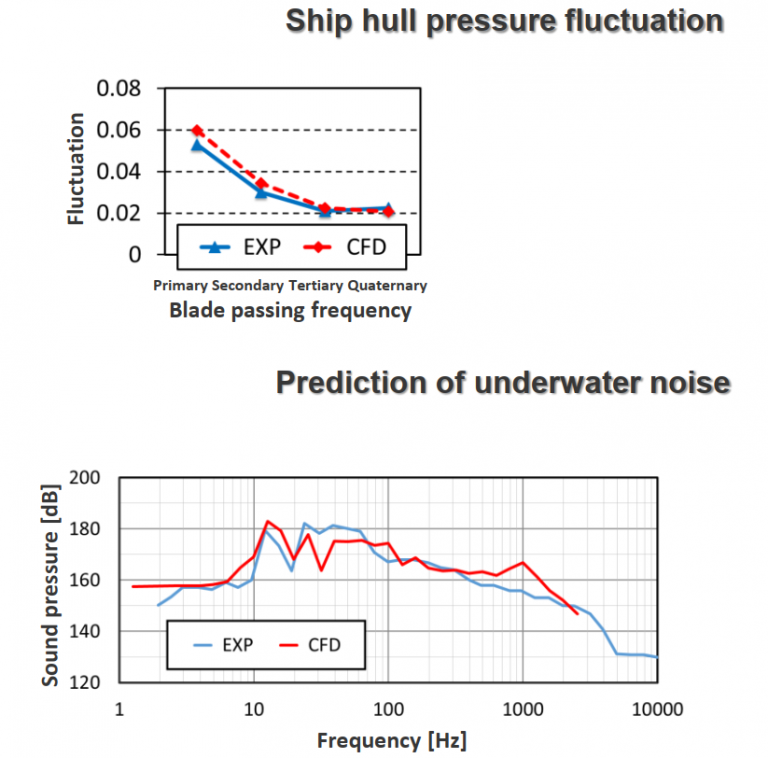

- Minimize vibro-acoustics, ensuring reduced environmental footprint and structural integrity.

- Provide accurate inputs to load calculations and system simulations.

Enteknograte offers a Virtual Engineering approach with CFD and FEA tools such as Ansys Fluent, StarCCM+ for flows simulation and FEA based Codes such as ABAQUS, Ansys, Nastran and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

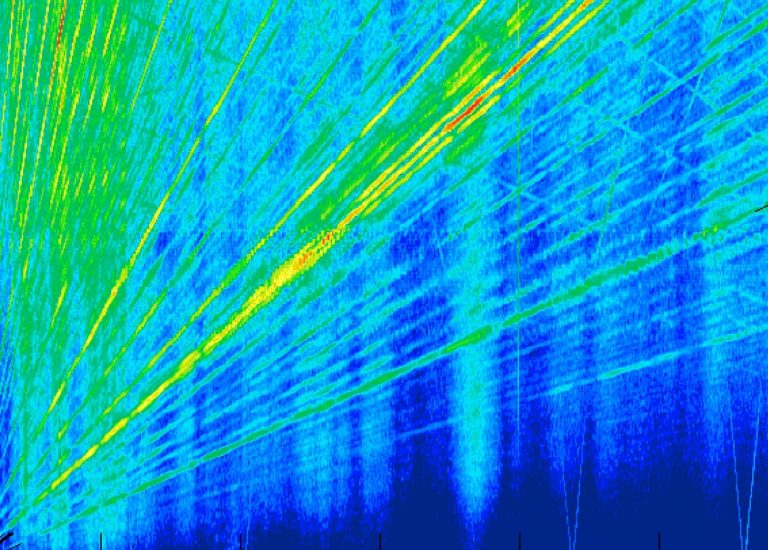

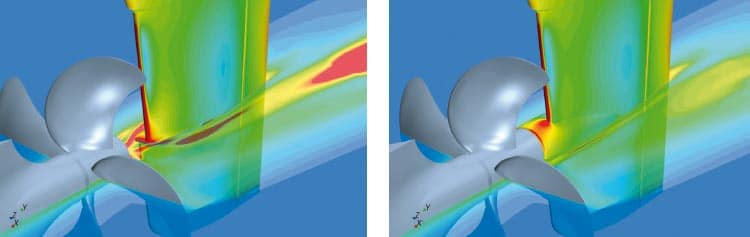

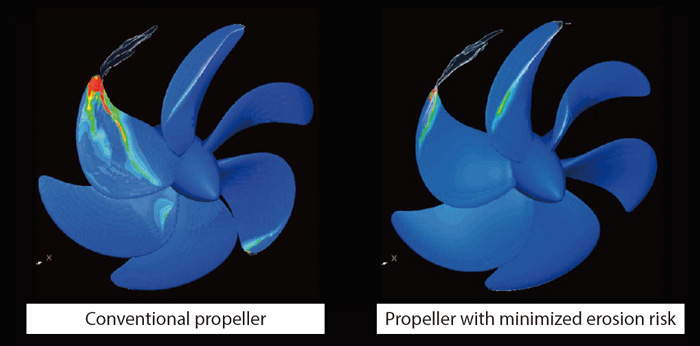

CFD Analysis of Cavitation for Marine and Shipbuilding

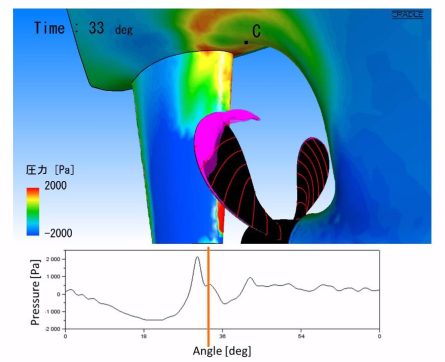

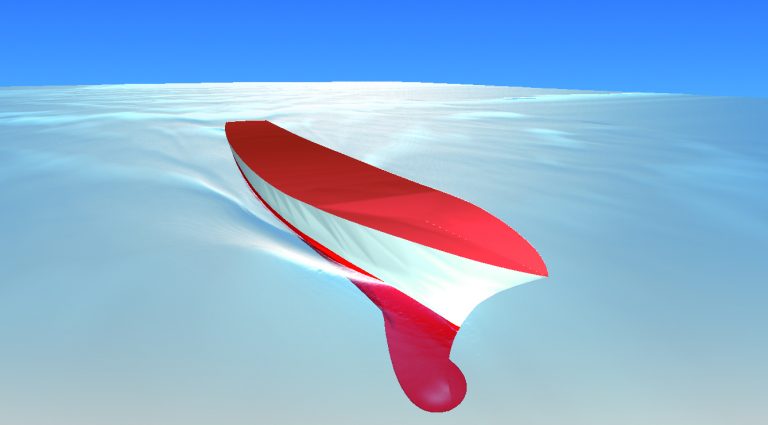

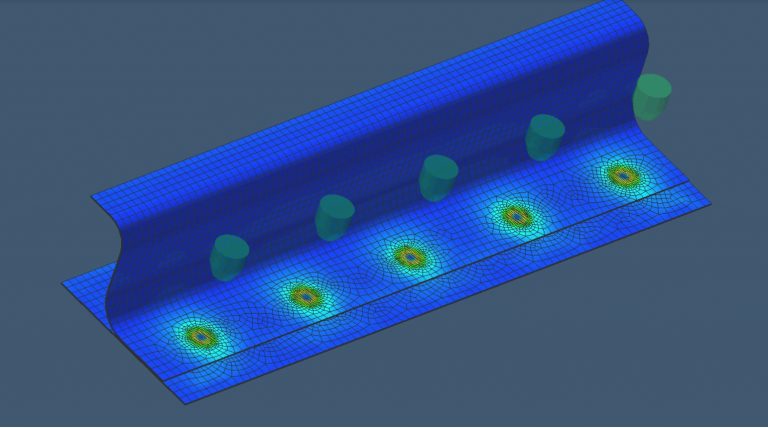

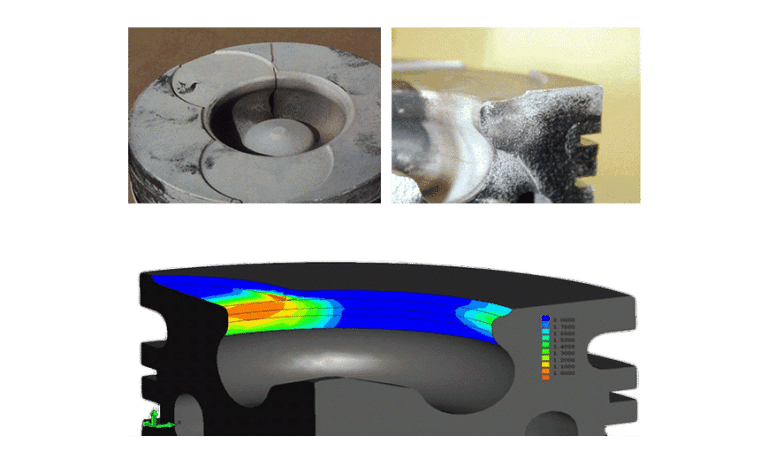

For water pumps, marine propellers, and other equipment involving hydrofoils, cavitation can cause problems such as vibration, increased hydrodynamic drag, pressure pulsation, noise, and erosion on solid surfaces. Most of these problems are related to the transient behavior of cavitation structures. To better understand these phenomena, unsteady 3D simulations Modeling Cavitation of cavitating flow around single hydrofoils are often performed and the results are compared to experiments.

Marine Propulsion System Design: Combination of CFD & FEA for Detailed Fatigue, Strength and Vibration Analysis

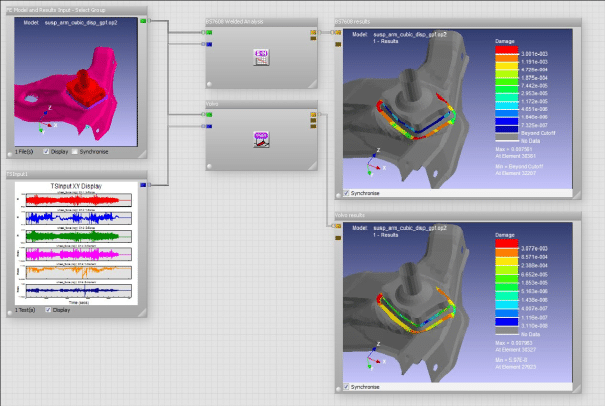

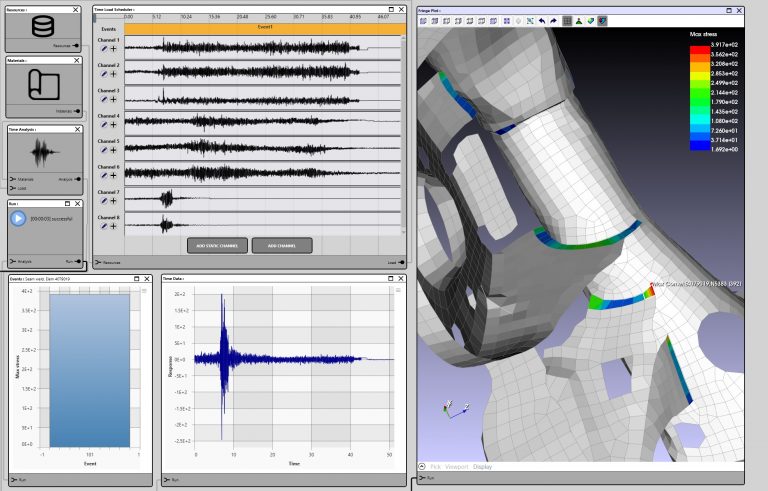

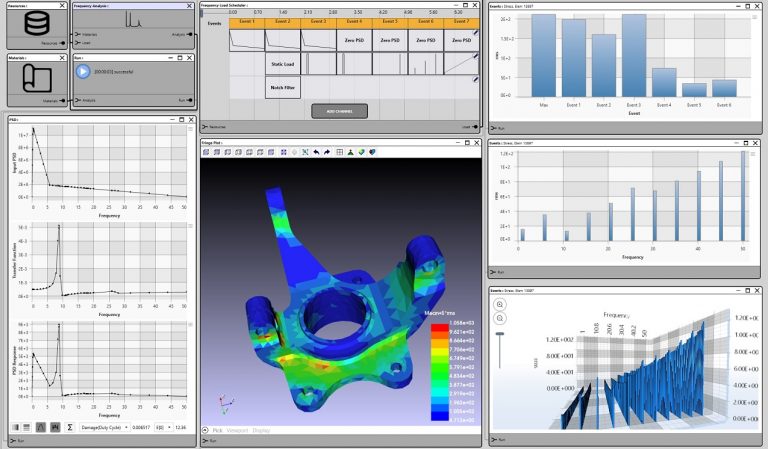

Marine propulsion system designers rely on the combination of CFD and FEA software for fatigue, strength and vibration analysis. Proper propulsion system/components analyses during the design phase help avoid delays in delivery and damage problems in operation, thereby reducing expensive off-hire. Professional and reliable software and experts is essential for the design of a robust system.

Deep knowledge and experience combining with advanced CFD and FEA software enable us to handle any problem with any level of complexity in very short time. We Use CFD tools such as MSC Cradle, Ansys Fluent, Siemens Star-ccm+ and FEA Tools such as Abaqus, Nastran and LS-DYNA with combination of very experienced engineers to help our customers in:

- Investigation of course keeping and turning ability

- Motions analysis of FPSOs (Floating production storage and offloading)

- Manoeuvring at low / variable speed in shallow and confined seaways/ unsteady maneuvers: tacking, gibing

- Torsional Vibration Simulation with Coupled CFD and FEA softwares to identify the interaction between components, an essential part of the system and functionality assessment

- (unlimited) deep water-Shallow water condition

- Floating wind turbine design and simulation including dynamic effects due to elastic response of wind, waves in rotor blades, the tower, and the mooring lines.

- Monohulls / conventional ships

- Multi hulls: catamarans, SWATH, trimarans

- Asymmetric ships (monohulls as well as catamarans)

- Submarines

- FEA simulation of torsional vibration regarding ice impacting on the propeller

- Fixed models as well as free to trim and sink conditions

- Coupled Hydrodynamic CFD Simulation with structural finite element analysis to Simulate transient strcutural behavior in irregular waves

- Added resistance in waves

- Combined drift and gyration

- Ship resistance analysis

- Hydrodynamic Interaction between Bodies: shielding effects, Forward speed effects

- Dynamic trim and sinkage behaviour

- Propulsion and propeller performance optimization

- Ship wake

- Shaft fatigue and lifecycle calculations of marine shafts torsional vibration stress levels based on low cycle, high cycle and transient fatigue

- Vortex induced vibration analysis

- Whipping and slamming impacts simulation: Wave-induced hull vibration for the assessment of hull girder collapse characteristics.

- Erosion CFD Simulation including hydrodynamics effects

- Offshore equipment stability: Buoyancy and centre of gravity studies

- Added masses for subsea hardware CFD calculations

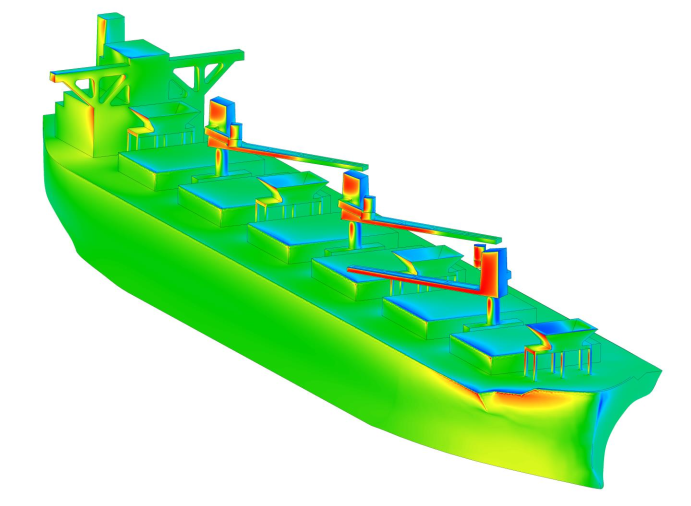

- Hull performance assessment and wave-making CFD solutions

- Sea keeping behavior in regular or irregular waves

- Calculation of drag and lift on appendages

- Sail or wing optimization

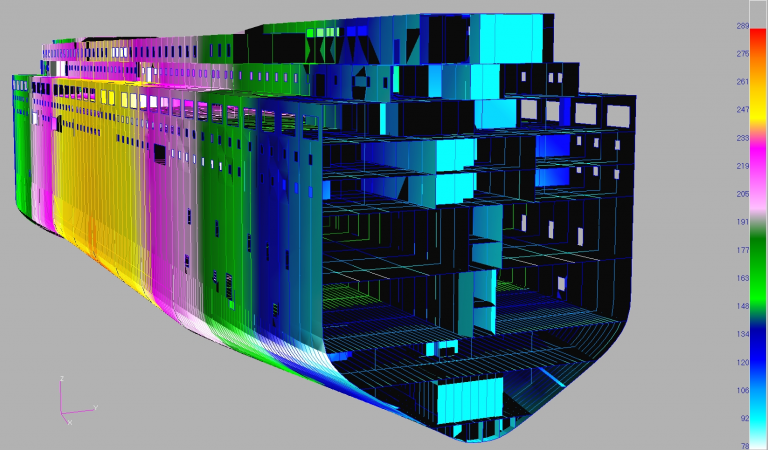

- Ship structural analysis and design with FEA software such as Ansys, Abaqus and Nastran

- Hydrodynamic plant & equipment

- Tidal Power System Hydrodynamic Design

- Optimal gearbox lubrication

CFD Optimization of Hull Form Including Hydrodynamics considerations

The hullform of a ship is decisive for its energy consumption and efficiency in that a large part of the overall resistance is determined by form effects and the aft body shape influences the propulsive losses. The shape related aspects are traditionally the domain of a ship model basin. While in the past numerous physical ship models have been created and tested in a towing tank to find the optimal solution, this role has been taken over by CFD, numerical methods which allow analyzing the performance of a ship hull before the first model is built. Enteknograte Engineering team use advanced CFD and Optimization software such as Ansys Fluent, Siemens Star-ccm+ and MSC Cradle to compute hull resistance at different stages of a design.

Coupling Hydrodynamic CFD Simulation in Ansys Fluent, Siemens Star-ccm+ and MSC Cradle with structural finite element analysis (Abaqus, Ansys) to Simulate most complicated industrial problem

Enteknograte has vast experience in the modelling of hydrodynamics using CFD simulation in a wide range of applications. The experienced CFD staff can offer an accurate and detailed analysis of the flow and be able to identify viable areas of improvement for implementation and design. This Simulation can be used to model:

- Hydrodynamic Interaction between Bodies: shielding effects, Forward speed effects

- Shielding effects of a pier adjacent to a ship, an important aspect in the design of breakwaters and how they affect mooring systems.

- Design and analysis of mooring systems, including intermediate buoys and clump weights

- Motions analysis of FPSOs (Floating production storage and offloading)

- Calculation of shielding effects of ships and barriers

- Multiple body interactions during LNG transfer

- TLP tether analysis

- Dropped object trajectory calculations

- Concept design and analysis of wave and wind energy systems including multiphase condition including hydrodynamic effects

- Simulation of lifting operations between floating vessels

- Discharging landing craft from mother ships

- Transportation of large offshore structures using barges/ships

- Float over analyses

- Motion analysis of spar vessels

- Static and dynamic initial stability including the effects of mooring systems and other physical connections

- Coupled Hydrodynamic CFD Simulation with structural finite element analysis to Simulate Transient structural behavior in irregular waves

- Coupled cable dynamics in static and dynamic analysis to modeling of mooring system loading and response in deep waters.

- Dynamic positioning system

- Towing force provided by a tug

- Damping system with unusual characteristics

- Suction force between two ships close together, or between a ship and the sea bed

Hydrodynamics & HydroAcoustics simulation for AIV (Acoustic Induced Vibration)

Ship Stability & Safety Analysis Including Hydrodynamics & Aerodynamics Effects

Cavitation in Propulsion Systems

Hydrodynamic Performance of Ship Hull: CFD Based Design

Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Floating, Fixed & Gravity-Based Structures Design Including Hydrodynamics & Aerodynamics Effects

Hydropower, Solar Power and Biomass

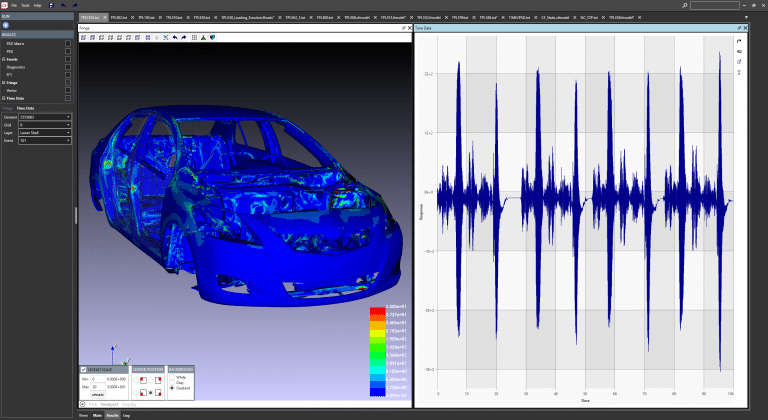

Structural Dynamics Integrity & Vibro-Acoustics Simulation for Marine & Shipbuilding Industry

Hydroplaning (Aquaplaning) Simulation

Turbine, Pump & Compressor (Axial or Centrifugal)

NVH based Design and Considerations for Marine and Shipbuilding Industry including Ship, Boat, Yacht, Vessels and offshore structures

The challenge for the NVH specialists is to support the concept and design development process by reliable recommendations just-in-time prior concept or design freeze. Enteknograte’s specialists particularly use advanced methodologies for NVH simulation and optimization for Marine and Shipbuilding Industry:

- FEA based Ship, Boat, Yacht, Vessels Powertrain

- Structural Optimization

- Optimization of Ship, Boat, Yacht, Vessels Engine Dynamics based on MBD ( Multi-Body Dynamics Simulation)

- Concurrent optimization of combustion efficiency with NVH considerations for Vessels

- Ship, Boat, Yacht, Vessels and offshore structures Interior Noise Simulation based on measurement and CAE

- Ship, Boat, Yacht, Vessels and offshore structures Exterior Noise Simulation with couple use of CFD and FEA solvers

- Objective Analysis of Sound Quality

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Electromagnetic Multiphysics

Acoustics and Vibration

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation

Fatigue Analysis of Welded Structures Using the Finite Element Method

Finite Element Analysis of Durability and Fatigue Life

Heat Transfer and Thermal Analysis

Multi-Phase Flows CFD Analysis