Fuel Injectors and Spray CFD Simulation

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

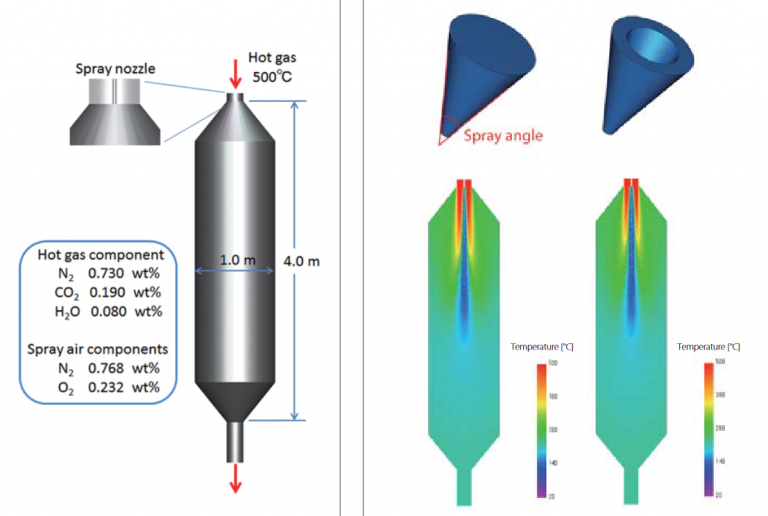

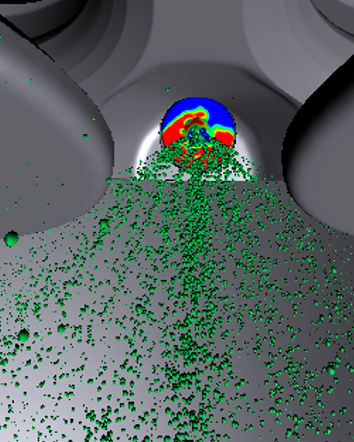

CFD software such as MSC Cradle, AVL Fire, Siemens Star-ccm+, Ansys Fluent and Converge is well equipped to simulate fuel injectors and spray processes including liquid atomization, drop breakup, collision and coalescence, turbulent dispersion, spray cavitation, drop-wall interaction, and drop evaporation. With combination of a one-dimensional model typically represents the complete injection system from the fuel tank to the injector, 3D CFD Solver focuses on the three-dimensional calculation of the fluid flow inside the injection nozzle.

Wide array of fuel injection simulation methodology, and robust and well-validated physical models allow us for accurate and computationally efficient simulation of these complex physical processes. In applications such as internal combustion engines, the fuel spray initiates, propagates, and dissipates very quickly on a very small spatial scale.

The combustion process can be strongly affected by the exact nature of the fuel spray: droplet velocity, size, distribution, and physical attributes and for dynamically capture the important physics of the injection process, we need a high-density grid around the spray.

Enteknograte engineering team use advanced CFD tools for simulation and analysis of the injection of liquid fuel via physical models for blob injection, injection distribution, variable rate-shape, discharge coefficient, and hollow cone and solid cone sprays and simulating the mixing and evaporation of multi-component fuel sprays.

Spray and Turbulence

Accurate spray and turbulence modeling is critical for predictive diesel and gasoline combustion simulations. In order to obtain results that are as realistic as possible, we use a wide variety of spray and turbulence modeling such as Reynolds-Averaged Navier-Stokes (RANS) and Large Eddy Simulation (LES) turbulence models.

For spray, simulate injection, breakup, vaporization, and other spray-related processes with detail are available. We can perform simulations that are dual fuel or multi-fuel and diesel and gasoline are not the only fuels that we can simulate.

Becasue of deep concern to engine manufacturers are the constantly evolving emissions regulations, To help meet these regulations, we simulate soot and NOx via its detailed chemistry. Soot emissions from gas turbine combustors are increasingly becoming a critical design factor as new particulate matter emissions regulations.

CFD Based Injection Nozzle Development

This simulation capabilities enable virtual design of: Reduce cavitation and avoid erosion in injection nozzles Achieve higher engine-out performance and lower engine-out emissions Performance Counts. In an early engine design stage, fuel injection details, such as needle lift and inlet pressure level, are not known. Thus, a virtual prototyping environment, consisting of 1D and 3D fuel injection simulations is extremely valuable.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

By using Accurate reaction mechanisms that representing every class of reaction important for combustion analysis and combination of advanced computational fluid dynamics (CFD) combustion simulation tools such as Kiva, Ansys Fluent, Ansys Forte, AVL Fire, Converge CFD, Siemens Star-ccm+ , MSC Cradle and System Modeling software such as Matlab Simulink and GT-Suite enable Enteknograte engineering team to reduce chemistry analysis time by orders of magnitude, virtually eliminating the bottleneck that chemistry integration produces during the simulation process.

Using Simulation to Optimize Reacting Flows and Combustion

From automobile engines to gas turbine generators, reacting flow and combustion is often the key to energy efficiency, emissions, lifespan, product yield, and other performance parameters. Simulation help look deeper into reacting flow and combustion issues to understand the complex chemical reactions, fluid flow, heat transfer, electrical performance, and other factors that determine the performance of your product. Simulation enables our engineers to evaluate more design alternatives more thoroughly than traditional prototype-based design and development methods.

Gas Turbine Combustion CFD Simulation: Detailed Chemistry

Fuel Injectors and Spray CFD Simulation

Spray, Combustion, Emissions, Shaft and Gear Systems, Acoustic Enclosures

CFD Simulation of Reacting Flows and Combustion

CFD Simulation of Engine Exhaust Aftertreatment

1D/3D Coupled Simulation and Co-Simulation: Detailed Chemistry & Multiphase Flow Modeling with 1D Modeling

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation

Finite Element Analysis of Durability and Fatigue Life

Multi-Phase Flows CFD Analysis