- Vehicle Thermal Management Simulation

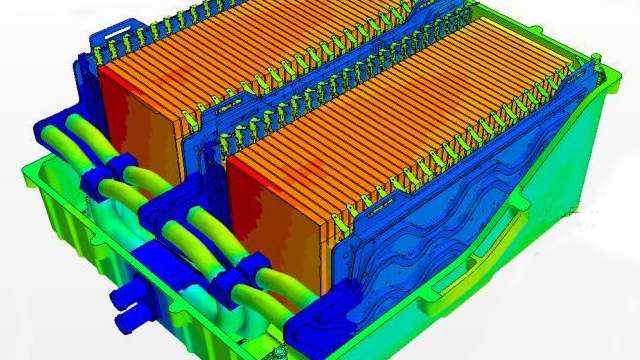

- Electronic Systems Cooling & Heating

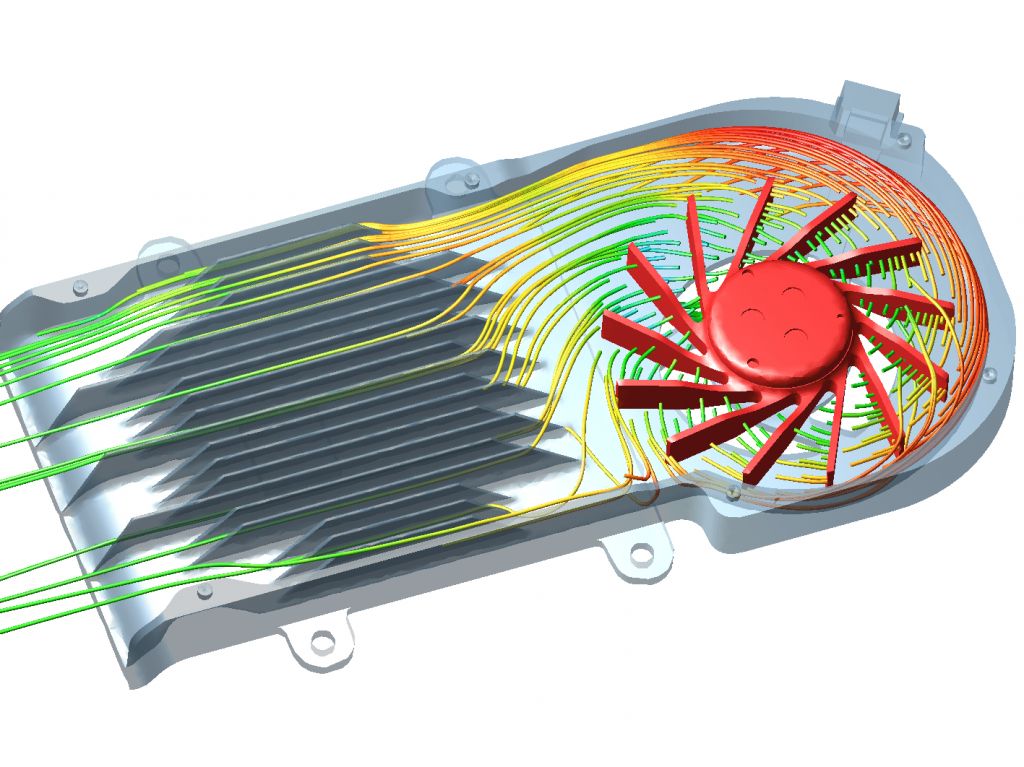

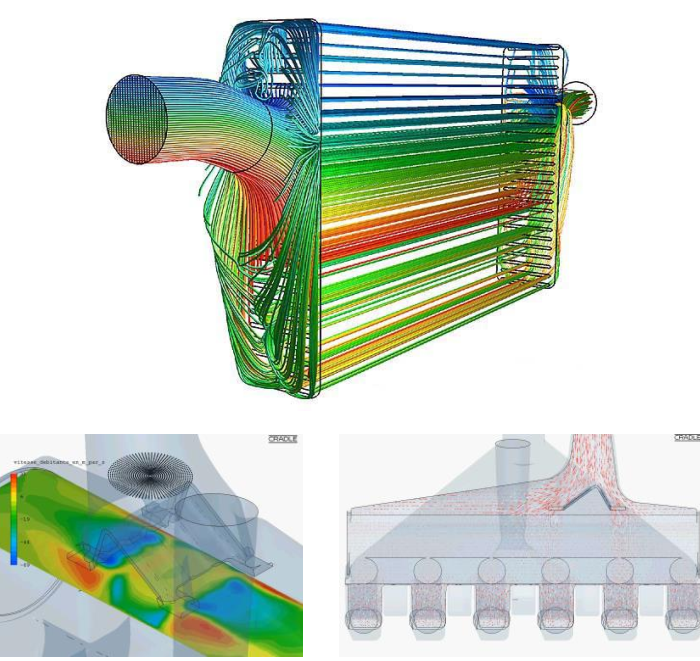

- Heat Exchangers: Simulation-Based Design for Thermal Performance

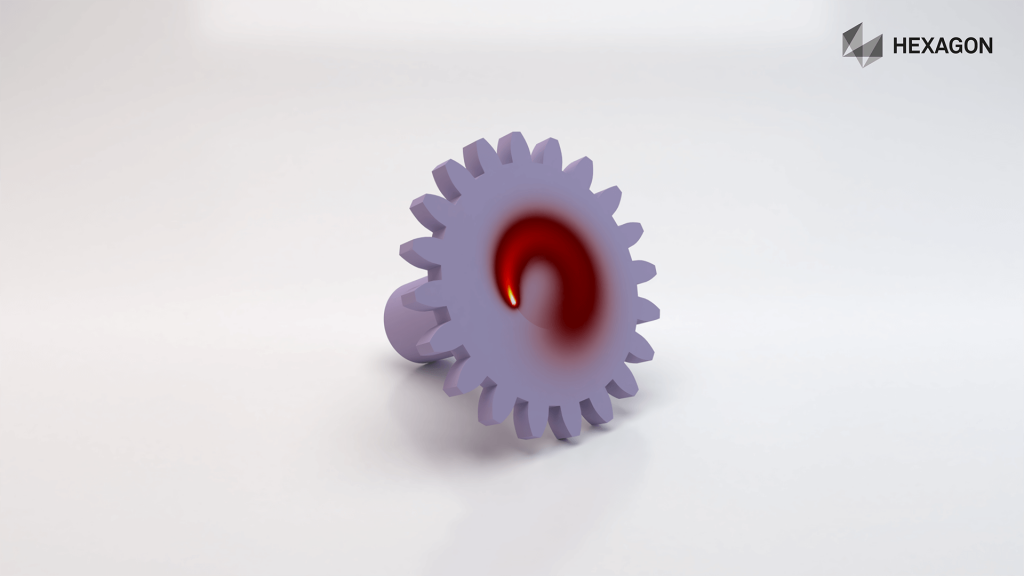

- Thermal Stress Simulation

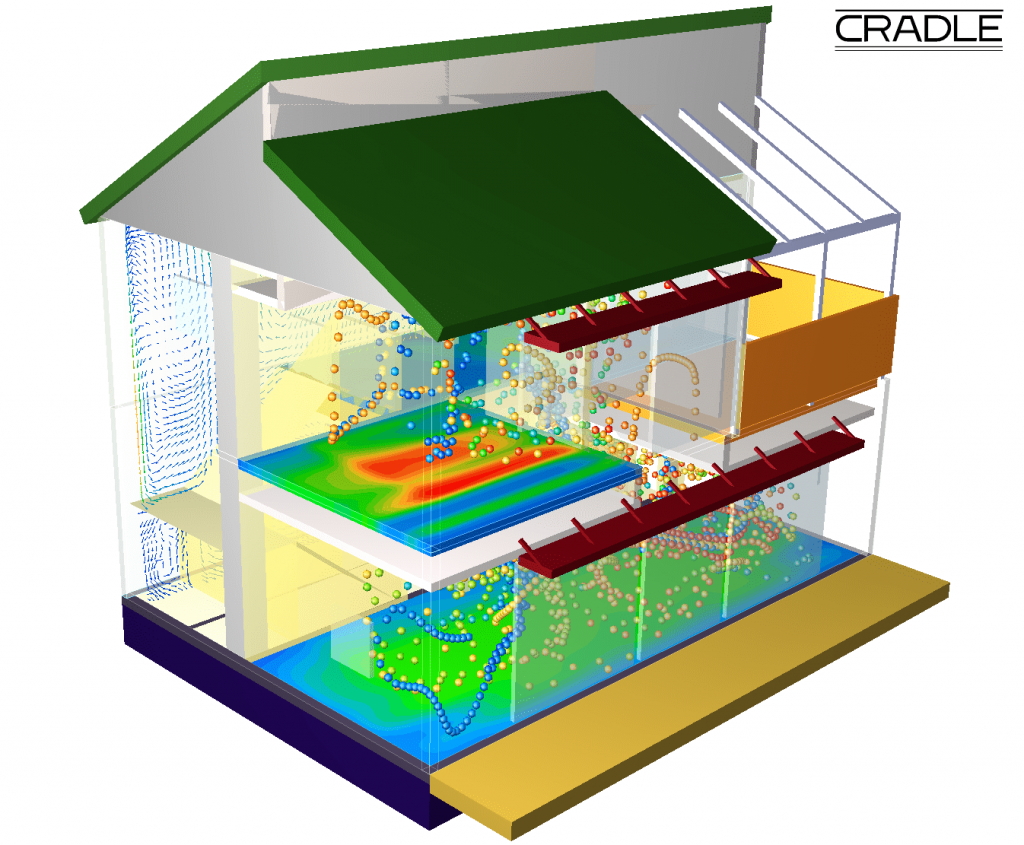

- Buildings Thermal Management: HVAC/Climate Control Analysis

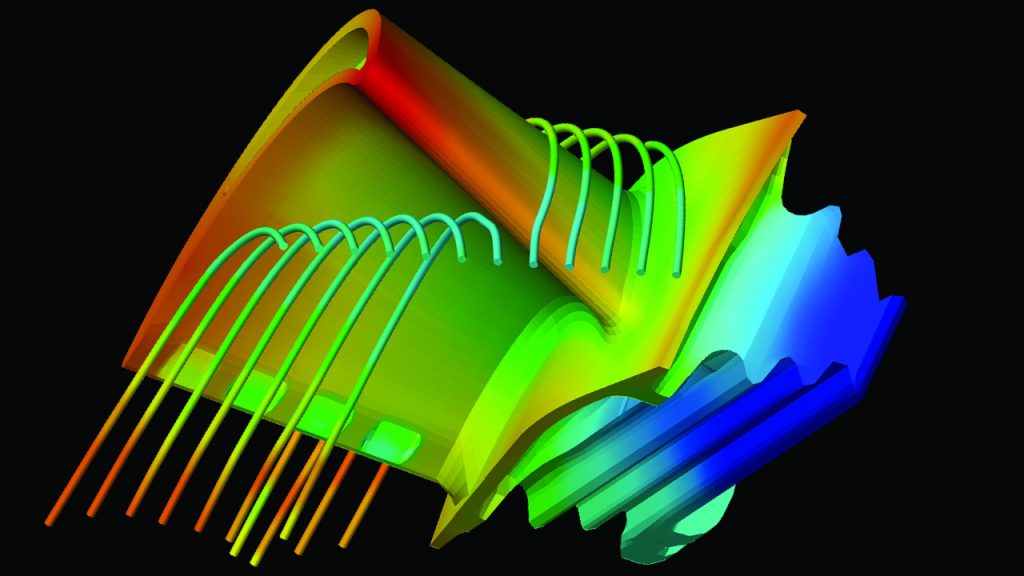

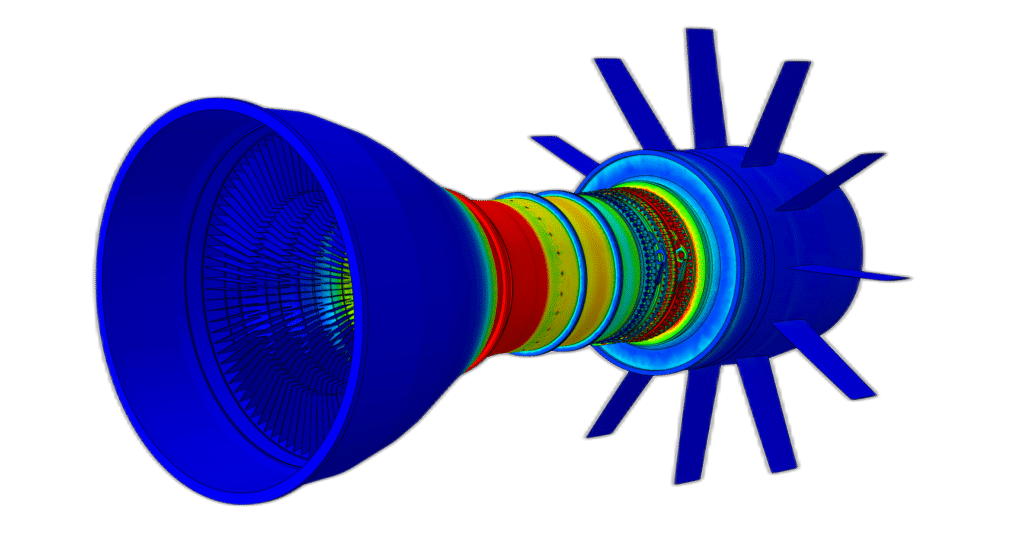

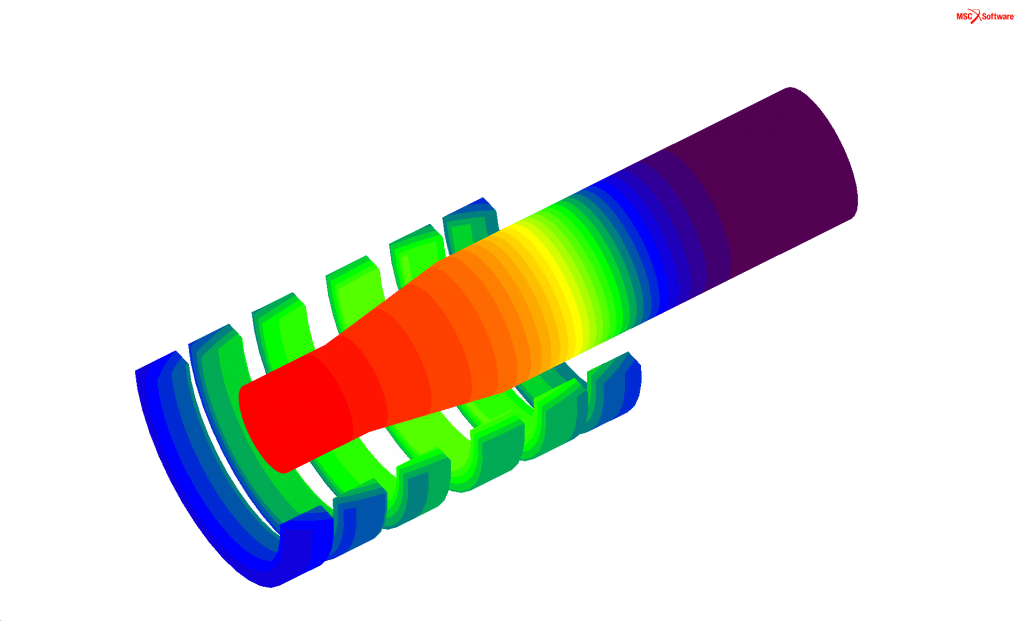

- Heat Transfer for Turbomachinery

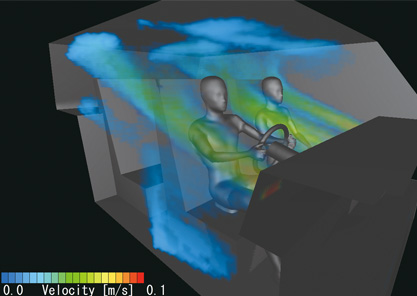

- Cabin Aerodynamics: Thermal Comfort & Noise Reduction

- Stress Relief Heat Treatment: Finite Element Simulation

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

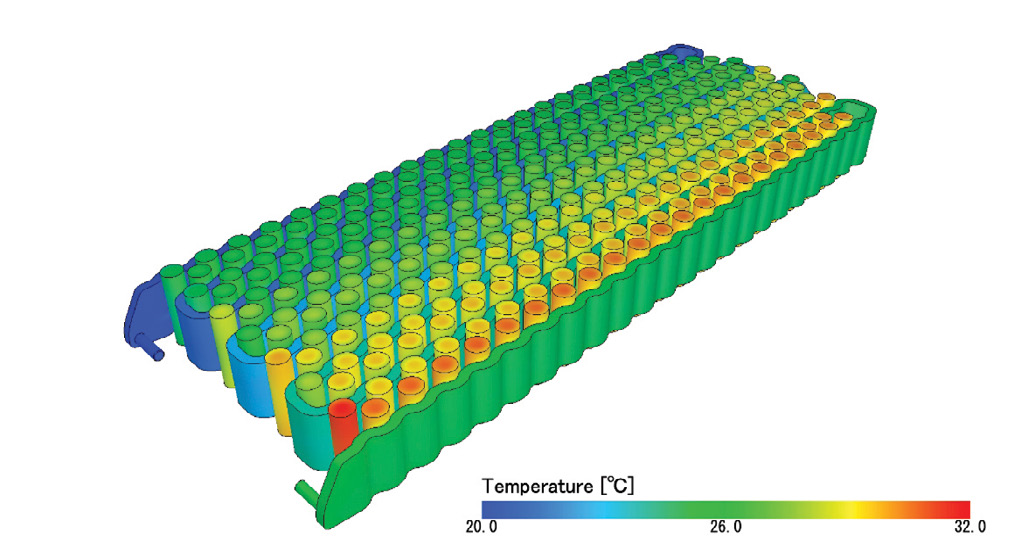

The effects of heat and thermal management of structures is more and more critical as performance limits are pushed further by the need to have lighter, smaller and more efficient designs. Convection, radiation and conduction loads are obvious, but the need to include the effect of power losses and thermal energy from friction and external sources such as pipe flows means that analysts need to have more tools at their disposal to simulate thermal models accurately.

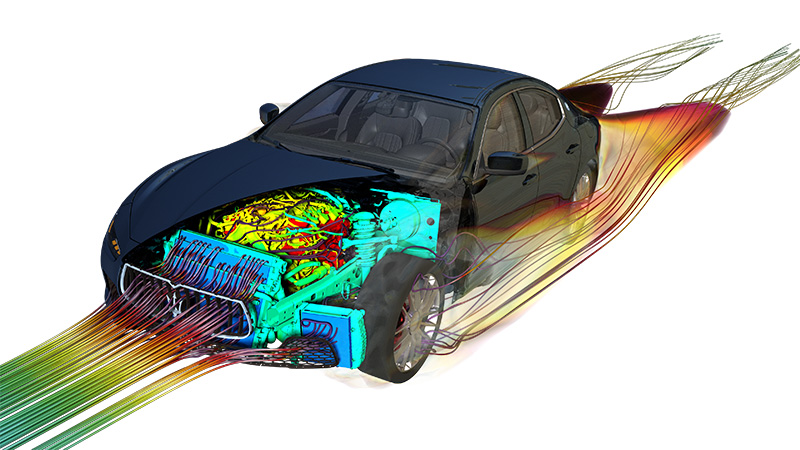

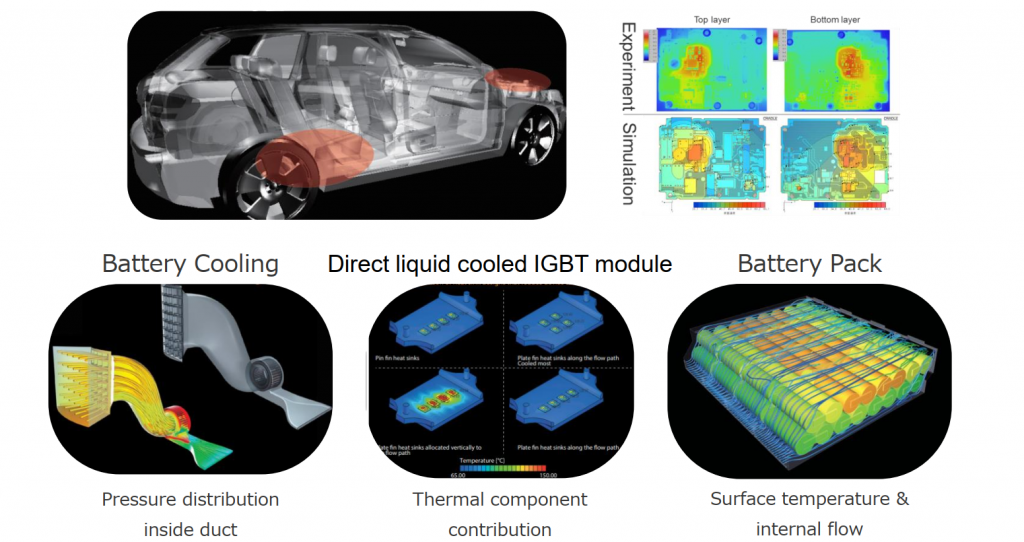

We analyze system-level thermal management of vehicle component, including underhood, underbody and brake systems, and design for heat shields, electronics cooling, HVAC, hybrid systems and human thermal comfort and covers a wide range of Industries like Automotive, Aerospace, Oil and gas, marine, medical devices, heavy engineering and Industrial and consumer appliances.

Our Finite Element (LS-Dyna, Ansys, Abaqus) and CFD simulation (Siemens Start-ccm+, Ansys Fluent , Ansys CFX and OpenFoam) for heat transfer analysis, thermal management, and virtual test process can save time and money in the design and development process, while also improving the thermal comfort and overall quality of the final product.

Why we use Coupled FEA-CFD?

Finite Element Analysis (FEA) is a powerful and well recognized tool used in the analysis of heat transfer problems. However, FEA can only analyze solid bodies and, by necessity thermal analysis with FEA is limited to conductive heat transfer. The other two types of heat transfer: convection and radiation must by approximated by boundary conditions. Modeling all three mechanisms of heat transfer without arbitrary assumption requires a combined use of FEA and Computational Fluid Dynamics (CFD).

With using CFD based design optimization solutions serve as an important link for our clients to realize their product promise right from concept to realization. Our team of CFD engineers in conjunction with experienced FEA Engineers for FSI and complicated industrial multiphysics problem is delivering solutions to major engineering verticals globally.

- Conduction, convection and radiative heat transfer

- Conjugate heat transfer

Fluid Structure Interaction for Thermal Analysis

Fluid Structure Interaction (FSI) calculations allow the mutual interaction between a flowing fluid and adjacent bodies to be calculated. This is necessary since all real structures are flexible, especially those that are large or subject to high fluid loads. The body forces generated by fluids flowing are highly sensitive to the shape and curvature of adjacent surfaces.

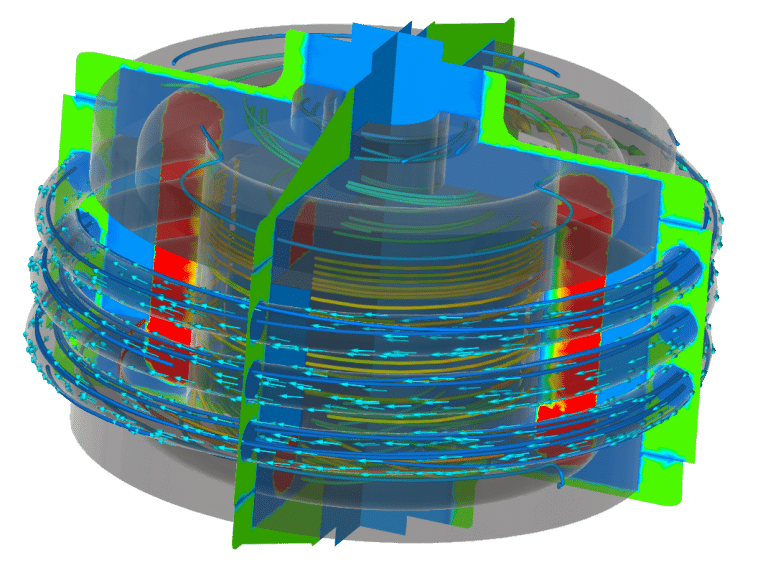

By coupling a CFD solver and the FEA solver, the deformation of a body resulting from the fluid loads and the subsequent modification of the flow field due to the newly deformed geometry can be computed iteratively. This technique allows aeroelastic instabilities such as flutter, to be detected and avoided early in the design cycle. Similarly, where structures are subjected to cyclic fatigue loading, such as rotor-stator interaction in compressor applications or vortex shedding around civil structures, these load effects can be accurately quantified to allow the fatigue life of the structure to be assessed.

Simulating the thermal performance of a product early in the design phase can save large amounts of time and money by getting the design of the early prototypes right from a thermal management standpoint, thus reducing the need for additional prototypes that might otherwise be required to diagnose and correct thermal issues. Simple computational fluid dynamics (CFD) software can be used to analyze thermal issues such as determining how heat is transferred through a fluid. But many problems are more complex, such as those that involve multiple mechanisms of heat transfer, where heat is transferred through both solids and structures.

Cases in which the fluids and structures involved in heat flow are closely coupled, so that thermal deflection of the structures affects the fluid flow, are also challenging. Engineers often need to understand how heat is transferred by a number of different mechanisms through a complicated interconnected system in order to understand how their product or process will perform under a given set of conditions. This point is one of the applications of FSI simulation with Coupled CFD-FEA method.

As in isolated FEA and CFD one of the most profound benefits of FSI analysis is the ability to conduct comprehensive, multi-point optimization of designs. This process allows us to optimize a design to a given set of performance parameters and can be used to tune frequencies, or maximize fatigue life or avoid harmful resonance.

Conjugate heat transfer (CHT)

Conjugate heat transfer corresponds with the combination of heat transfer in solids and heat transfer in fluids. In solids, conduction often dominates whereas in fluids, convection usually dominates. Efficiently combining heat transfer in fluids and solids is the key to designing effective coolers, heaters, or heat exchangers.

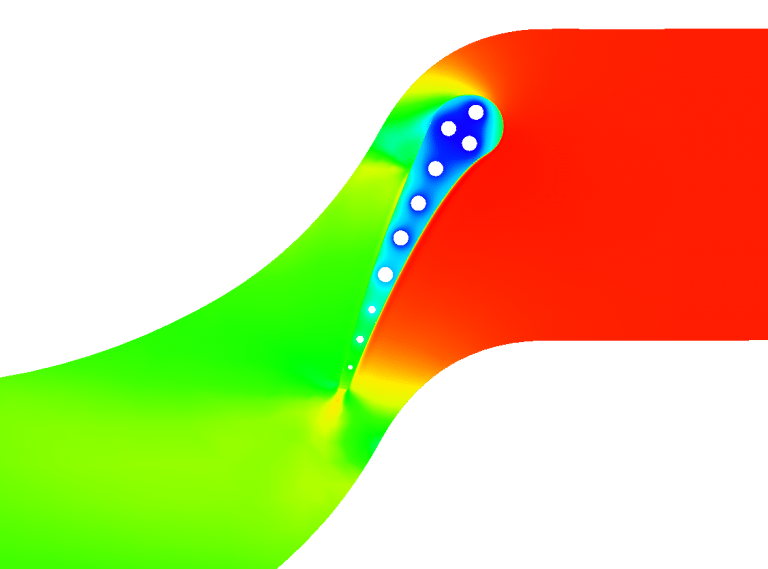

Optimizing heat transfer between fluids and solids is critical in many types of industrial equipment such as pre-heaters, engine blocks, cylinder heads, turbine blades, chemical reactors and reformers. Conventional heat transfer analysis is often limited by dependence on wall correlations that are valid only for certain types of equipment and specific operating ranges; it does not provide the detailed understanding of local flow and heat transfer behavior required for designs to be truly optimized.

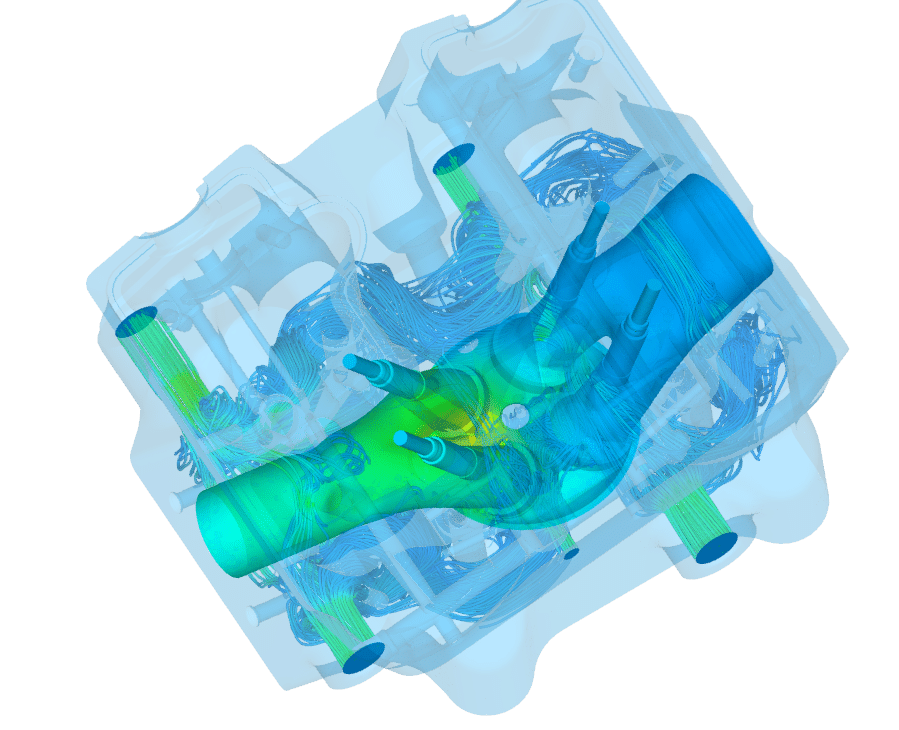

A typical CHT simulation might involve three domains: a single-phase combusting air-fuel mixture outside a pipe, the pipe wall and multiphase flow of a liquid inside the pipe wall.

CHT can model conduction through the wall. If the pipe is translucent, radiative heat transfer can also be modeled simultaneously among the three domains. If the pipe material is permeable, the diffusion of a contaminant or chemical could also be modeled.

Conditioning (HVAC) system

Regulations and customer demands put pressure on rail designers to deliver passenger coaches with comfortable climates. CHT is used to model the boundary of the fluid interior to the exterior wall of the vehicle, and to predict surface temperatures of walls that may be touched by passengers, as well as channels that exchange heat with the inside of the car. The ability to accurately predict HVAC system performance with simulation enables our engineers to get the design right the first time, making it possible to reduce the amount and cost of wind tunnel testing.

One-Way FSI

Solving thermal problems with CHT limits the engineer to the physical models that are contained within the CFD solver. More complex problems, such as those involving complex multimaterial structures or more accurate heat transfer coefficient (HTC) boundary conditions, can be solved by linking the CFD solver to a structural solver. Transferring solid temperature fields from CFD CHT simulations to a structural thermal system make it possible to use advantage of FSI simulation.

The temperatures or HTCs calculated by CFD, and also the surface loads if desired, calculated by the CFD solver are transferred to the structural finite element analysis (FEA) code and FEA code calculates the heat transfer and thermal fields in the structure as well as thermal–mechanical stresses. A characteristic of a one-way fluid structure interaction (FSI) solution is that the stresses and deformations calculated in the structural solver are not passed back to CFD to update the mesh and recalculate the flow.

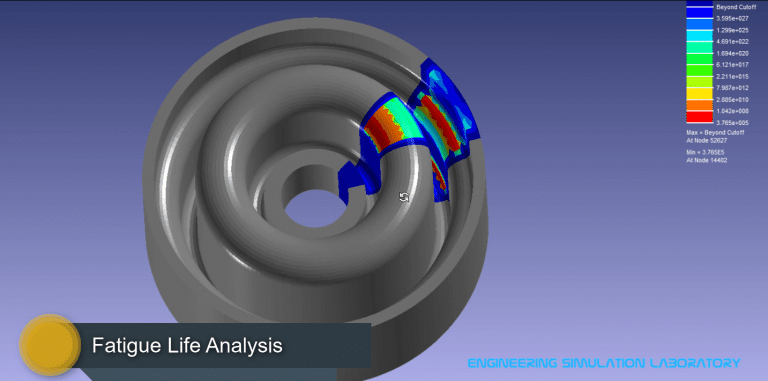

Enteknograte’s engineers also used the shape optimization methods to optimize heat transfer based on problem conditions. Also, we use Simulia FE-SAFE, Ansys nCode DesignLife and FEMFAT for fatigue analysis to calculate different type of fatigue safety factors based on the results of thermo-machnical simulations. The new design delivers the long life and high quality that the Enteknograte’s customers have come to expect.

Two-Way FSI: Two-way coupled CFD and structural (FEA)–Thermal simulation

Applications such as leakage paths and thin film flows where thermal-stress induced structural deformation affects fluid flow present an even more difficult simulation challenge. These applications can be simulated with two-way coupled CFD and structural thermal simulation. With this approach, the fluid flow solution is applied to the structure and the deformation of the structure is in turn applied to the fluid flow at each time step of the simulation. Two-way CFD and structural thermal simulation made it possible to set up a transient simulation that simultaneously solves the heat transfer coefficients (HTC) and near wall temperatures in the fluid

Failure to properly manage thermal performance can lead to inefficient energy use, uncomfortable or even unsafe temperatures, suboptimal performance and lower than expected product life. Engineering simulation is essential to diagnosing and evaluating solutions for thermal problems early in the design process when they can be corrected at the least possible cost and time. Enteknograte’s engineering team cane accurately predict thermal performance across a wide range of operating conditions with deep knowledge in FEA and CFD and coupling them, enable us the capabilities required to address the most difficult thermal design challenges:

- Thermal shock resistance for brittle materials immersed in a fluid.

- Cracking mechanism in materials subject to high temperature gradients

- Furnace or burner failures

- Radiators and heat exchanger flow balance

- Cross flow heat exchanger liquid gas

- Pins and turbolators pressure drop and trade-offs

- Kilns transient analysis

- Thermal shocks on Solar panels

- Cooling jackets, cooling holes position and dimensions

- Automotive exhaust, turbogas exhaust

- Defrosting ducts for automotive and home appliances

- Lamps, automotive headlights

Equipped with multi-domain knowledge and deep technical expertise, Enteknograte engineering team offers global strategic engineering and environmental consultancy that specializes in performing 1D-Multi-Physics CAE simulations, 3D FEA and CFD thermal analyses and design optimization to a wide variety of clients and industries. Typical applications include:

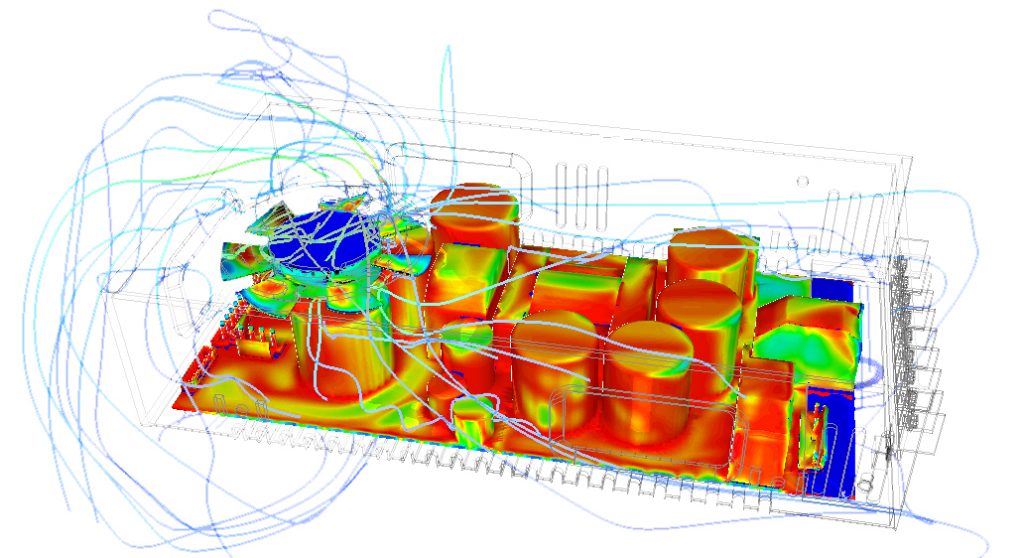

- PCB Thermal Design

- VTOL, e-VTOL and UAM – Urban Air Mobility Systems Thermal Design

- Electronic Enclosures & Cooling Systems

- Heat Exchanger Design

- Heat Shield & Insulation Design & Optimization

- Underbody and engine compartment thermal protection.

- Brake cooling

- Key-off/soak

- HVAC system performance

- Cabin and passenger thermal comfort

- Defrost and demist

- Thermal comfort in buildings

- Gas turbine cooling

- Heat Transfer in Porous Media

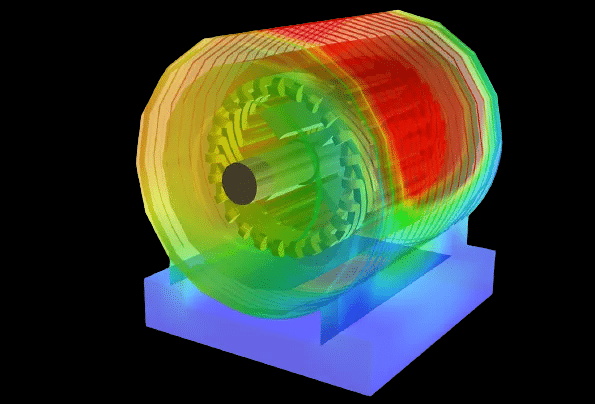

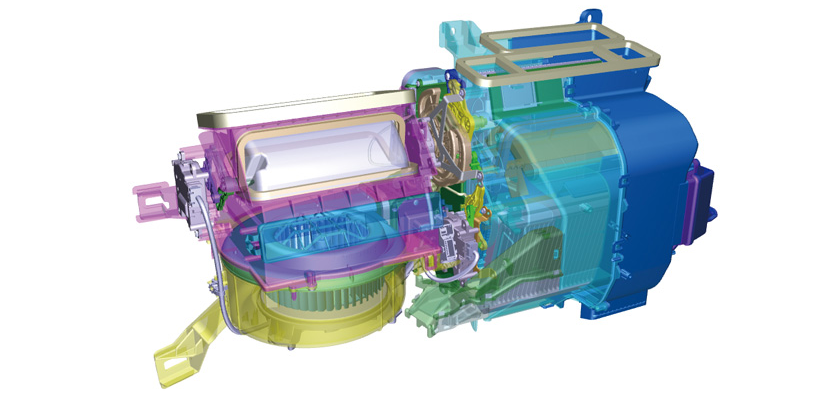

- Turbo machines thermal design

- Combustion and multiphase flows.

- IC Engine flows

- Thermal analysis of radiator with heat pipe

Vehicle Thermal Management Simulation

Electronic Systems Cooling & Heating: Simulation-Based Thermal Management Design

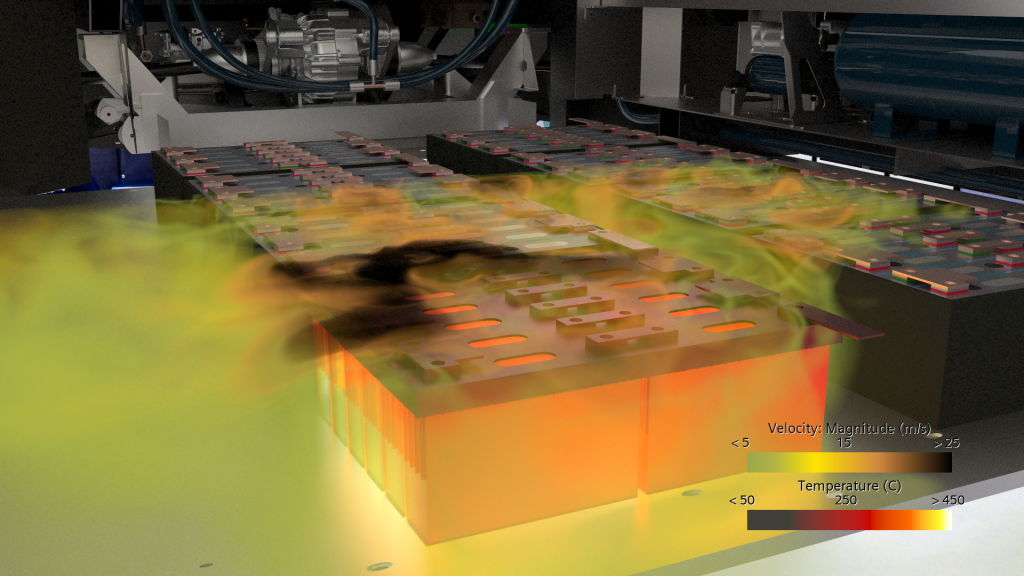

Battery Thermal Management: Simulation Based Design

Underbody & Underhood Simulation for Thermal Management

Heat Exchangers: Simulation-Based Design for Thermal Performance Optimization

Thermal Stress and Fatigue Simulation: Coupled CFD and Finite Element Approach

Thermal Management in Buildings: HVAC/Climate Control Analysis

Heat Transfer Simulations for Turbomachinery Including FSI Effect with Coupled FEA & CFD

Cabin Aerodynamics: Passenger’s Thermal and Acoustic Comfort

Stress Relief Heat Treatment: Finite Element Simulation

Electromagnetic Multiphysics FEA & CFD Based Simulation

MultiObjective Design & Optimization of Turbomachinery: Coupled CFD & FEA

Hydrodynamics CFD simulation

Additive Manufacturing and 3D Printing

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

eVTOL (Electric Vertical Take-Off and Landing) & UAM (Urban Air Mobility)

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Seat Design: Finite Element and CFD Simulation for Static & Dynamic Comfort, Whiplash, Acoustic & Thermal Comfort, Crash Test

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte’s Engineering team with efficient utilizing real-world transient thermal analysis with FEA – CFD coupling if needed, with FEA Solvers such as Abaqus, Ansys, LS-Dyna, Nastran and MSc Marc and computational fluid dynamics (CFD) solver like MSC Cradle, Siemens Star-ccm+ and Ansys Fluent for advanced Thermal simulation and have clear knowledge about the assumptions and simplifications that must be made to get results with required accuracy.

Finite Element Analysis of Durability and Fatigue Life

Electric Motors Cooling

Creep and Creep-Fatigue Interactions

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation