Reactor Design & Combustion Engineering for Chemical and Petrochemical Processing

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

Using comprehensive multiphysics simulation platform that encompasses fluid mechanics, structural mechanics, impact and safety analyses, customized mixing tools, pressure vessel analysis, electromagnetic and control systems, and heat and mass transfer analyses we can model a diverse range of reactions, including gaseous and liquid, single-phase and multiphase, and homogenous and heterogeneous. Our engineering simulation for reactor design including CFD for chemical reactor design, FEA structural and thermal analysis and instrumentation and control software used for design and analysis of chemical reactors enable our reaction engineers to answer what-if questions as they design and enhance reactors performance, energy usage, reactor yield and product uniformity.

Enteknograte engineering simulation for reactor design software tools help a wide range of customers to simulate and improve a wide variety of reactors and reaction types.

- Stiff chemistry

- Competing and parallel reactions

- Catalytic reactions

- Heterogeneous and homogeneous reactions

- Surface and volumetric reactions

- Laminar and turbulent flows

- Single-phase and multiphase reactions

- Fluidized bed reactions

- Multi-tube reactors

- Membrane reactors

- Microreactors

- Stirred tank reactors

- Fixed reactors

- Autoclave reactors

- Emulsion

- Hydrogenation

We optimize reactor performance by investigating the effects and impacts of feed locations, vessel geometries and internals, vibrations, failures, dead spots, shear rates, resident time distributions, hot spots, and particle size distributions.

Enteknograte offers a Virtual Engineering approach with CFD and FEA tools such as Ansys Fluent, StarCCM+ for flows simulation and FEA based Codes such as ABAQUS, Ansys, Nastran and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

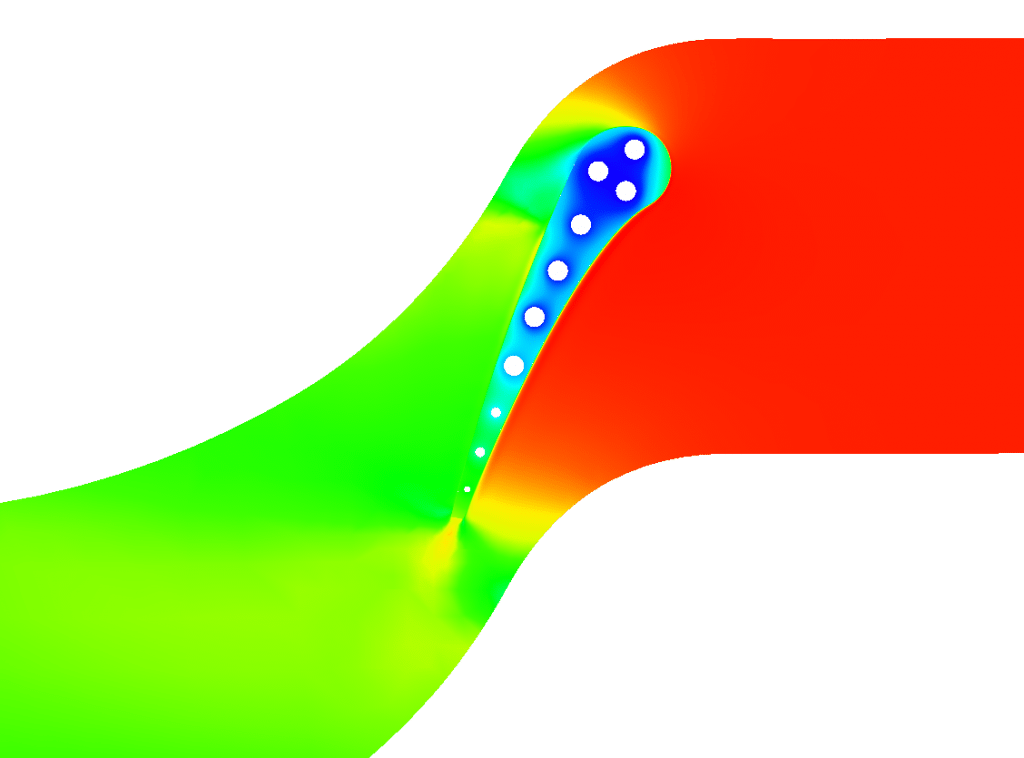

CFD Simulation and Optimization of Combustion

CFD for combustion systems enable the simulation of a broad range of particulate concentrations, from dilute flows to packed beds. Simulations provide local velocities, particulate concentrations and traces, composition of combustion gases, fuel conversion rates, temperatures, and other critical data. These insights enable Enteknograte’s combustion engineers to investigate operational issues such as local temperature peaks, combustion efficiency and mixing problems. Enteknograte’s engineering team simulation are helping customers to overcome the following and many other combustion-related challenges:

- Improve burner configurations in industrial furnaces

- Reduce NOx emissions from petroleum refineries

- Investigate novel clean energy technologies

- Predict and improve CO emission rates

- Model and minimize thermal stresses in combustion equipment

- Reduce soot formation in furnaces

- Optimize flare stack designs

Conjugate heat transfer (CHT)—the simultaneous prediction of heat transfer in both the fluid and solid portions of the domain—is of critical importance in a full-engine simulation. The accuracy of the predicted combustion in the cylinder is dependent on the temperature boundary conditions in the cylinder. By considering heat transfer in the metal components (e.g., the cylinder head, liner, piston, etc.) in the simulation, the cylinder wall no longer has a user-specified temperature, but instead has temperatures predicted as part of the system simulation.

Reactor Design & Combustion Engineering for Chemical Processing

Heat Transfer-Equipment Design and Analysis for Chemical Processing: Comprehensive CFD & Finite element method

Mixer Design and Analysis with FEA and CFD based-Simulation

Multiphase Simulation for Chemical Processing

Filtration System Design and Engineering for Chemical Processing with CFD & Finite Element Method

Chemical Processing Simulation and Design: Coupled CFD, FEA and 1D-System Modeling for Heat Transfer, Filtration & Mixer System , Reactor Design & Combustion Engineering

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

By using Accurate reaction mechanisms that representing every class of reaction important for combustion analysis and combination of advanced computational fluid dynamics (CFD) combustion simulation tools such as Kiva, Ansys Fluent, Ansys Forte, AVL Fire, Converge CFD, Siemens Star-ccm+ , MSC Cradle and System Modeling software such as Matlab Simulink and GT-Suite enable Enteknograte engineering team to reduce chemistry analysis time by orders of magnitude, virtually eliminating the bottleneck that chemistry integration produces during the simulation process.

Gas Turbine Combustion CFD Simulation: Detailed Chemistry

Fuel Injectors and Spray CFD Simulation

Electromagnetic Multiphysics

CFD Simulation of Reacting Flows and Combustion

CFD Simulation of Engine Exhaust Aftertreatment

1D/3D Coupled Simulation and Co-Simulation: Detailed Chemistry & Multiphase Flow Modeling with 1D Modeling

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Simulation of Plasma Based Devices: Microwave Plasma and RF Plasma Analysis with Coupling Particle in Cell (PIC), MHD, CFD and FEA Solvers

Finite Element Analysis of Durability and Fatigue Life

Multi-Phase Flows CFD Analysis