FEA (Finite Element Analysis) & CFD Based Simulation of Blast, Explosion & Fire: Blast Resistance Certification with Protection Against Ballistic Attacks for Windows, Doors, Buildings and Vehicles

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

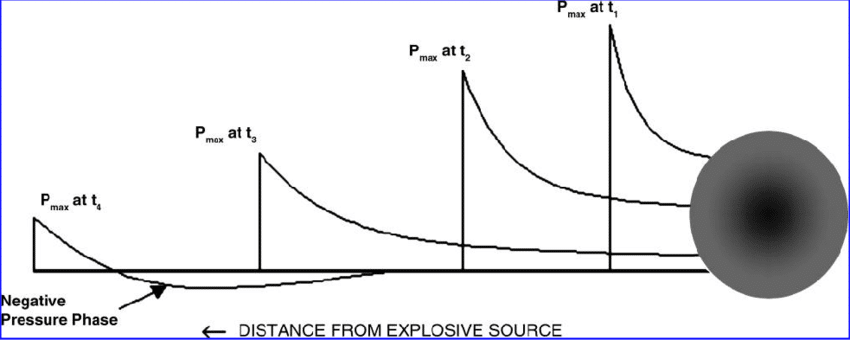

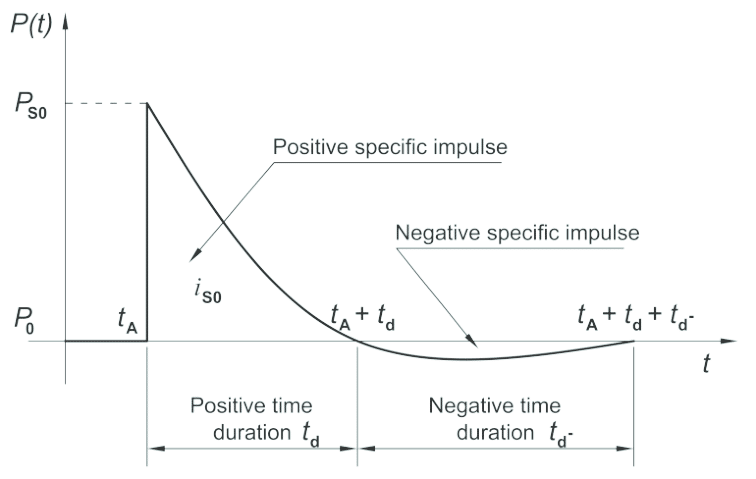

Contemporary design requirements associated with the protection of life and property often require consideration for blast effects resulting from either accidental or intentional explosions. Proper treatment of blast effects in structural systems requires specialized knowledge ranging from non-linear responses of structures to short-duration dynamic loading. Enteknograte’s Research engineers have extensive training and experience in managing all structural response considerations related to high-energy events, including blast design, explosion effects and mitigation, and finite clement modeling of blast events. Design and validation of structures against blast loads are important for modern society in order to protect and secure its citizen. Since it is a challenge to validate and optimise protective structures against blast loads using full-scale experimental tests, we have to turn our attention towards advanced numerical tools like the CFD and finite element method.

FEA (Finite Element Analysis) Simulation and Analysis of Blast Door in Near Field Explosion

Simulation numerical methods for Blast loads

Several different finite element techniques can be used to describe the response of structures due to blast loads. Some of these are:

- A pure Lagrangian formulation,

- An initial Eulerian simulation (to determine the load) followed by a Lagrangian simulation (for the structural response) and

- A hybrid technique that combines the advantages of Eulerian and Lagrangian methods to have a full coupling between the blast waves and the deformation of the structure.

Ideally, all blast simulations should be carried out using the fully coupled Eulerian-Lagrangian approach, but this may not be practical as the computational time increases considerably when going from a pure Lagrangian to a fully coupled Eulerian-Lagrangian simulation.

Engineering Simulation software that we use for Blast and Explosion such as air blast, Underwater explosion (UNDEX) and Fragmentation

Enteknograte engineers simulate the Blast and Explosion with innovative CAE and virtual prototyping available in the non-linear structural codes MSC Dytran, LS-DYNA, Ansys Autodyn, and ABAQUS. Enteknograte Engineers can simulate any type of Blast and Explosion such as air blast, Underwater explosion (UNDEX) and Fragmentation due to blast to survey structural integrity in High Rate Loading Condition.

Our engineers have strong backgrounds in FEM(Finite Element Method) and complicated Multiphysics simulation that need deep knowledge and are fluent in the codes like LS-DYNA, Ansys and ABAQUS. We can develop special purpose user subroutine (UMAT) based on clients need to empower simulation environment to overcome any complicated problem in Blast and explosion load condition and user defined material constitutive equation for composites and special purpose Concrete including fracture mechanics of concrete in different strain rate.

Computational Fluid Dynamics for BLAST, Explosion and Fire simulation

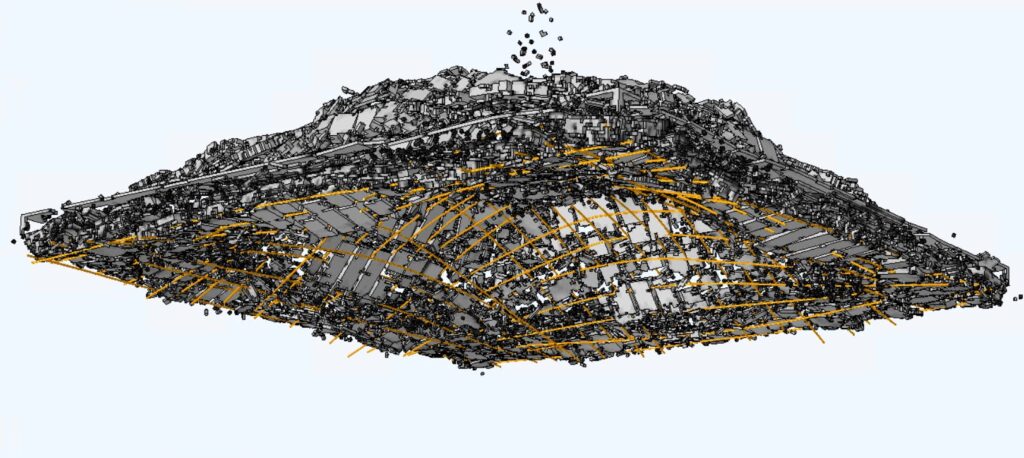

Blast loads on buildings can be determined through the use of computational fluid dynamics (CFD) computer programs. The basic premise of CFD modeling is to discretize the building and surrounding area encompassing the blast source and adjacent obstacles into small regular cells of finite volume and then solve the governing equations for conservation of mass, momentum, and energy within each cell, taking into account the effects of adjacent cells.

Among other uses, CFD is utilized to simulate the propagation of blast waves in an environment of obstacles, to simulate pressures on unusually-shaped buildings, to simulate leakage through openings into buildings, to simulate interior explosions, and to simulate near-field explosion effects. Where applicable, CFD can be used as an alternative to the more commonly used empirical methods.

It should be understood that CFD results are sensitive to modeling techniques and the software used. CFD programs can employ a true first principles approach which includes turbulence modeling and detailed combustion, or a semi-empirical approach where simplifications of the explosion source are made, based on test data and guidance, to simplify and speed the analysis. Phenomological models are sometimes used to simplify the analysis by using numerical modeling of selected explosion phenomena to capture important features of blast propagation. As with most simulations, the greater the detail of the model, the greater the potential accuracy of the result.

By using Accurate mechanisms that representing every class of explosion and Fire important for this analysis and combination of advanced computational fluid dynamics (CFD) simulation tools such as MSC Cradle, Ansys Fluent, AVL Fire, Converge CFD, Siemens Star-ccm+ enable Enteknograte engineering team to most detailed simulation of Fire and Explosion in industrial and defense projects.

Enteknograte Research Blast engineering and Explosion mitigation capabilities include:

- The use of methods ranging from classical to nonlinear transient Finite Element Analysis (FEA)

- Industrial equipment subjected to accidental explosions

- Commercial curtain wall and window systems

- New construction and retrofit of existing systems

- Hardening of historical buildings

- Inventive solutions for unusual applications

Design procedures for blast, explosion and fire analysis of offshore structures

Explosions, fires and other accidents are major risks in the offshore industry. Extreme loads arising for structural from accidents create a challenge engineers in the design of safe and weight-efficient structures. The use of design procedures based on state-of-the-art computational technology allows for weight-optimised structural designs that meet defined safety requirements. The finite element method (FEM) and computational fluid dynamics (CFD) as a computational tools has been extensively used in the offshore industry. It has been applied both for global and local simulation to study the behavior of the offshore structures.

The following aspects are normally considered in order to achieve an optimum design for blast-resistant walls and partitions:

- Definition of design explosion and fire loads

- Establishment of the behavior of materials to be used for the design for high rate loads

- Determination of the behavior and strength of walls by means of non-linear FE modelling

FE modelling for offshore structures resistant to explosions and fires

Design procedures for creating offshore structures resistant to explosions and fires are normally based on the selection of design principles such as deterministic, probabilistic and risk-based design.

Methods used in designing structures that are resistant to explosions and fires include simplified methods and non-linear FE modelling and analysis. FE models involve accurate description of modelling techniques including modelling of structures, materials, and fire and explosion loads.

Safety doors must be built to meet OSHA, MSHA, NFPA Standards, FM Global Standards, European ATEX Directives and other many other standards when needed. Our advanced finite element simulation-based design for blast, explosion and fire will help you to satisfy all aspect of regulations in design step.

Assessment of fire and explosion loads

Enteknograte performs assessment of fire and explosion loads using state-of-the-art CFD software. Based on assessments of fire and explosion loads, deterministic or probabilistic models of loads are established for direct use in the design process for offshore installations.

Enteknograte carries out structural design verification as well as studies of structures subjected to fires and explosions. Complex FE models of structures are developed and used in response and structural strength simulations. We use advanced numerical techniques to real-world behavior capturing of systems in high rate loading in numerous cases, such as validate military vehicle designs, new infrastructure protection solutions or personal armour.

Combinated Security: Blast Resistance with Protection Against Ballistic Attacks

Attack Specifications

- EN 1627 Pedestrian door-sets, windows, curtain walling, grilles and shutters – Burglar resistance – Requirements and classification

- LPS 1270 Requirements & testing procedures for the LPCB approval & Listing of intruder resistant security glazing unit

- LPS 1175 Requirements and testing procedures for the LPCB certification and listing of intruder resistant building components, strongpoints, security enclosures and free-standing barriers

- EN 356 Glass in building – Security glazing – Testing and classification of resistance against manual attack.

Ballistic Specifications and Standards

- EN 1063 Glass in Building – Security Glazing – Testing and Classification of Resistance Against Bullet Attack

- UL 752 Standard for Bullet-Resisting Equipment

- BS 5051 Bullet-resistant glazing – Part 1: for interior use- Part 2: for Exterior use

- NIJ 0108.01 US National Institute of Justice Standard-Test and Certification for Ballistic Resistant Materials

- EN 1522/3 Windows, doors, shutters and blinds – Bullet resistance – Requirements and classification / Test method

- BSI PAS 68:2013. Impact test specifications for vehicle security barriers

- STANAG 2920. Ballistic tests for personal armour.

- STANAG 4164. Test procedures for armour perforation of anti-armour weapons

- STANAG 4190. Test procedures for measuring behind armour effects of anti-armour weapons

References:

- UK Government. Protecting Crowded Places. Design and Technical Issues

- UK Government. Crowded Places. Equality Impact Assessment of Guidance and Response to Recommendations

- UK Government. Crowded Places. The Planning System and Counter-Terrorism

- UK Government. Crowded Places. A Response to the Consultation

- UK Government. Working together to protect Crowded Places

- USA TM5-853. Security engineering project development

- USA TM5-855-1. Design and analysis of hardened structures to conventional weapons effects

- USA UFC 3-340-02. Structures to Resist the Effects of Accidental Explosions, USA, 2008

- USA UFC 4-010-01. DoD Minimum Antiterrorism Standards for Buildings

- U N D e p a r t m e n t o f Safety and Security: Blast Protection for Windows

- European Commission: A comparison of existing standards for testing blast resistant glazing and windows

- Comparison of US Blast Design Guidance Documents

Design and simulation based assessment of woven Composites performance in high velocity impact to pass NIJ (US National Institute of Justice Standard-Test and Certification for Ballistic Resistant Materials)

Design and simulation based assessment of Ceramic based Composites performance in high velocity impact to pass NIJ (US National Institute of Justice Standard-Test and Certification for Ballistic Resistant Materials)

Blast Specifications Test Standard

- GSA-TS01:2003 Standard Test Method for Glazing and Window Systems Subject to Dynamic Overpressure Loadings

- EN 13541 Glass in building – Security glazing – Testing and classification of resistance against explosion pressure

- EN 13123-2 Windows, doors and shutters – Explosion resistance – Requirements and classification

- ASTM F1642, Standard Test Method for Glazing and Glazing Systems Subject to Airblast Loadings

- ISO 16933, Glass in buildings — Explosion-resistant security glazing — Test and classification for arena air-blast loading

- EN 13124-1, Windows, doors and shutters — Explosion resistance — Test method — Part 1: Shock tube

- EN 13124-2, Windows, doors and shutters — Explosion resistance — Test method — Part 2: Range test

- EN 135411), Glass in building — Security glazing — Testing and classification of resistance against explosion pressure

- N. F. International Standards for Blast Resistant Glazing

- US Army Technical Manual 5-855, Fundamentals of protective design for conventional weapons

Fire Specifications Test Standard

- UL 10C Positive Fire Pressure Tests of Door Assemblies

- EN 1363-1 Fire resistance tests –Part 1: General Requirements

- EN 1364-1 Fire resistance tests for non-load-bearing elements – Part 1: Walls

- BS 476 Part 22 Fire tests on building materials and structures

- EN 1634-1 Fire resistance and smoke control tests for door and shutter assemblies, openable windows and elements of building hardware

- HOSDB 70/08. Determination of the explosion resistance of litter and recycling bins – Method

- HOSDB 21/09. Test standard for Protected Spaces in Buildings (Explosion Resistant Doors and Walls)

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae(Simufact, Digimat, Nastran, MSC APEX, Actran Acoustic solver), ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Composite Material Design and Optimization

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Oil, Gas and Petrochemical Industries: Finite Element and CFD Simulation-Based Design

Finite element analysis of concrete: Discrete cracking, Smeared crack and XFEM for concrete fracture and damage Simulation

CFD and FEA in Civil Engineering: Seismic Design, Earthquake, Tunnel, Dam, Concrete Structures and Geotechnical Multiphysics Simulation

Marine and Shipbuilding Industry: Finite Element and CFD Based Simulation and Design

CFD Simulation of Reacting Flows and Combustion

FEA and CFD Simulation for Aerospace and Defense

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Crash Test and Crashworthiness

Simulia Abaqus: Crash Test, Fracture & Damage, Blast & Explosion, Impact & Penetration, Thermal Analysis, Drop Test, Acoustics and Vibro-Acoustics

Ansys AUTODYN: Explicit Software for High Velocity Impact, Blast & Explosion, Fracture & Damage

Ansys LS-DYNA Multiphysics Solver: Industry-Leading Explicit Simulation Software for Drop Tests, Impact and Penetration, Smashes and Crashes, Occupant Safety.

MSC Dytran: Explicit Transient Dynamic Solution for Crash, Impact, Blast, Explosion and Fluid-Structure Interaction