MSC Co-Simulation - where Multiphysics gets Real

Co-simulation provides engineers with a unique, more complete & holistic performance insight by coupling together multiple simulation disciplines. Everything from acoustics to multibody dynamics (MBD), Aerodynamics , hydrodynamic vibration, complex heat transfer, to structural analysis, and explicit crash dynamics can be connected together in MSC.

MSC Co-Simulation Technologies

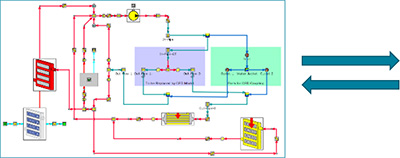

Depending on the type of analysis, engineers can use MSC solutions in two ways – Co-Simulation (applying multiple physics to the model simultaneously) or Chained Simulation (passing load case results from one analysis to the next).

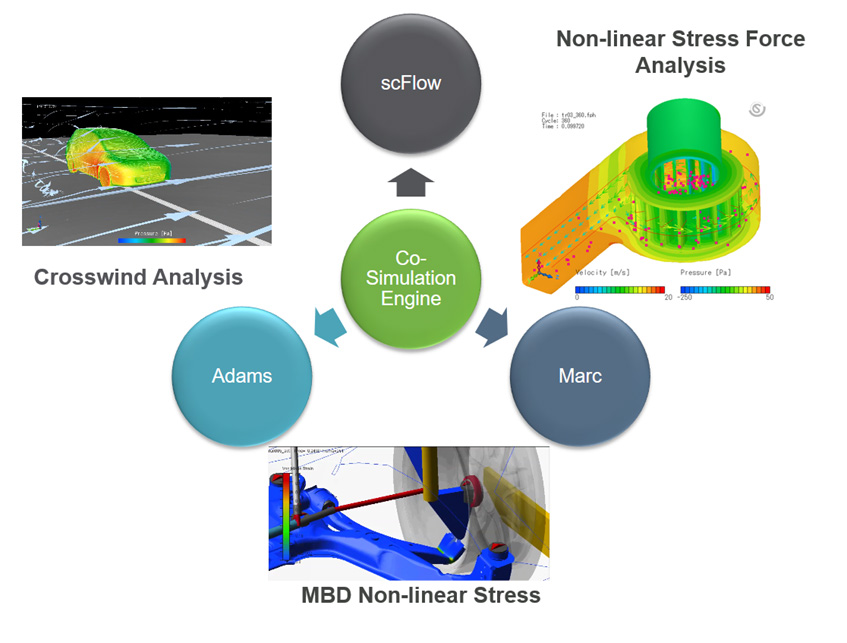

MSC CoSim Engine

The MSC CoSim Engine has been developed in order to provide a co-simulation interface for the direct coupling of different solvers/disciplines with a multi-physics framework. This first version, readily available today, enables engineers to set up co-simulation models between Adams, Marc, MSC Nastran and scFLOW.

Other Open Co-Simulation Solutions

Besides the CoSim Engine, MSC also supports a list of other co-simulation methodologies, including the Functional Mock-up Interface (FMI), Adams Marc Co-Simulation Interface (ACSI) and so on.

Chained Simulation

Chained simulation allows CAE engineers from different departments to integrate multiple disciplines sequentially and improve the overall simulation accuracy. For example, passing the road loads data from an Adams Full Vehicle model to the downstream MSC Nastran model for the stress & durability analyses.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae(Simufact, Digimat, Nastran, MSC APEX, Actran Acoustic solver), ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

1D/3D Coupled Simulation and Co-Simulation: Detailed Chemistry & Multiphase Flow Modeling with 1D Modeling

Hydrodynamics & HydroAcoustics simulation for AIV (Acoustic Induced Vibration)

Ship Stability & Safety Analysis Including Hydrodynamics & Aerodynamics Effects

Cavitation in Propulsion Systems

Hydrodynamic Performance of Ship Hull: CFD Based Design

Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Floating, Fixed & Gravity-Based Structures Design Including Hydrodynamics & Aerodynamics Effects

Hydropower, Solar Power and Biomass

Structural Dynamics Integrity & Vibro-Acoustics Simulation for Marine & Shipbuilding Industry

Hydroplaning (Aquaplaning) Simulation

Turbine, Pump & Compressor (Axial or Centrifugal)

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Electromagnetic Multiphysics

Acoustics and Vibration

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation

Fatigue Analysis of Welded Structures Using the Finite Element Method

Finite Element Analysis of Durability and Fatigue Life

Heat Transfer and Thermal Analysis

Multi-Phase Flows CFD Analysis

NVH & Acoustics for Hybrid & Electric Vehicles

eVTOL (Electric Vertical Take-Off and Landing) & UAM (Urban Air Mobility)

Finite Element Simulation of Crash Test and Crashworthiness with LS-Dyna, Abaqus and PAM-CRASH

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation

Vehicle Thermal Management Simulation

Finite Element Analysis of Durability and Fatigue Life

Multibody Dynamics

Additive Manufacturing and 3D Printing

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae(Simufact, Digimat, Nastran, MSC APEX, Actran Acoustic solver), ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.