CAEfatigue: FEA Based Fatigue, Durability & Random Response Solution

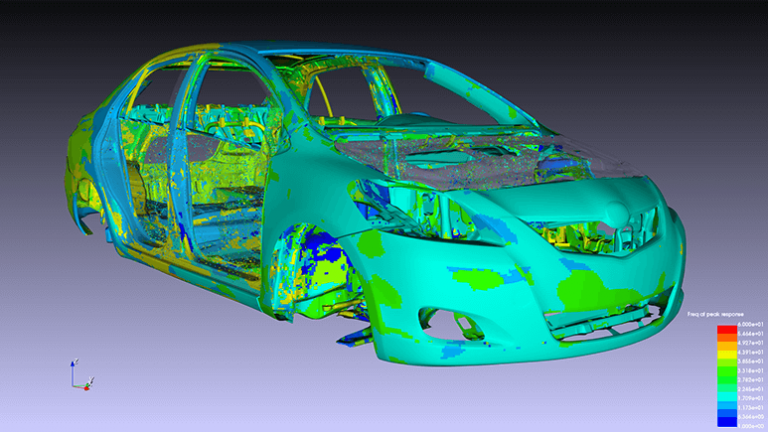

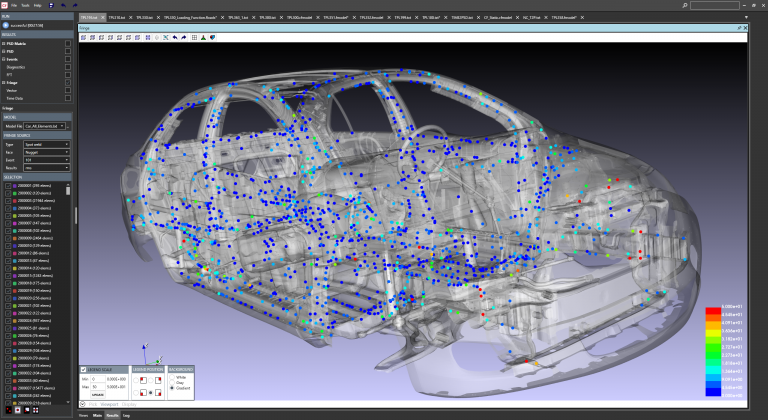

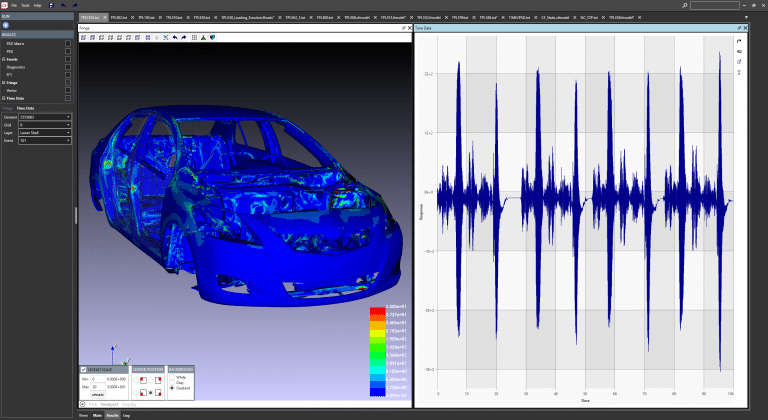

CAEfatigue is a random response and vibration fatigue solver for the frequency domain plus a fatigue solver for the time domain. It works with mixed random and deterministic loadings or standard time domain-based loadings to provide fatigue life and damage predictions, as well as several forms of response statistics. It is exceptionally fast, easy-to-use and capable of handling very large models. The software is sold in 4 different package configurations – Premium, Frequency, Random, and Time. Click the above tabs to learn more about each specific solution.

Democratizing Fatigue Analysis for the Masses

Response analysis, fatigue analysis, and the use of a graphical interface have traditionally suffered from a lack of democratization; that is to say, only expert users have been fully capably of using the technology. CAEfatigue aims to change this.

Two interfaces to the software are available – a Control File, text-based interface is provided for the advanced Users to help rapidly create an input control file that is needed to run an analysis. Many variables are either used in default mode or are automatically calculated based on an understanding of the system being analyzed.

Also available is a Process Flow graphical-based interface, provided to help novice users quickly gain an understanding of the technology without the need to understand the structured format of the control file interface. The interface is simple and intuitive to use.

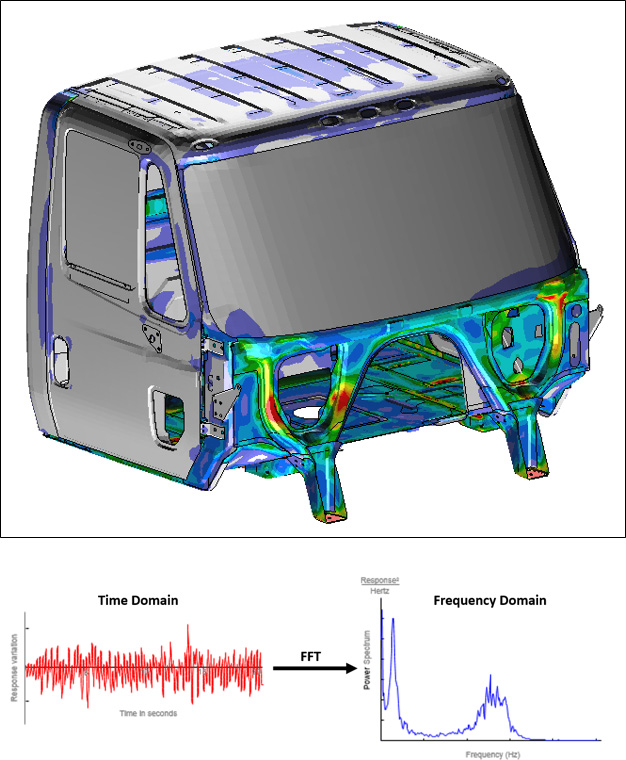

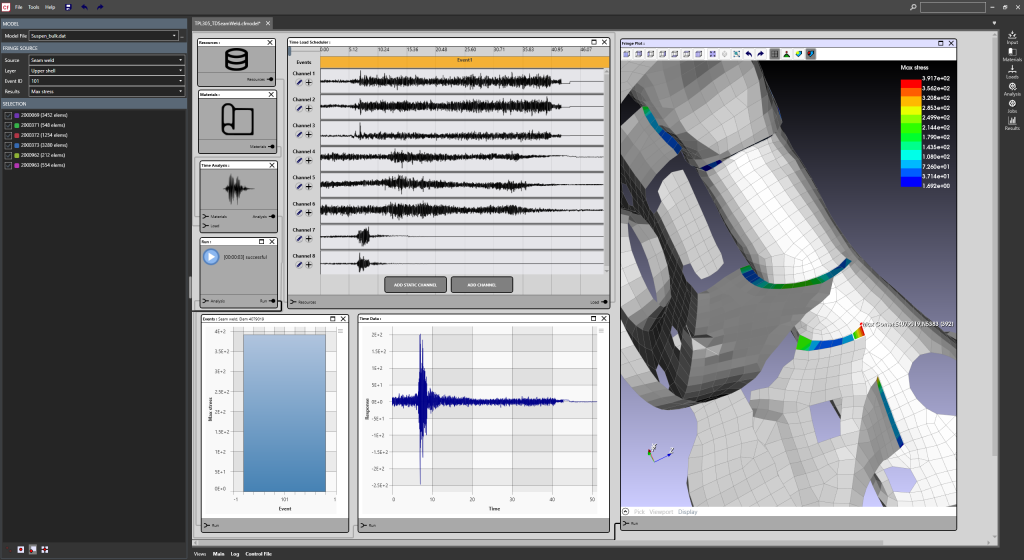

Time Domain Fatigue Analysis

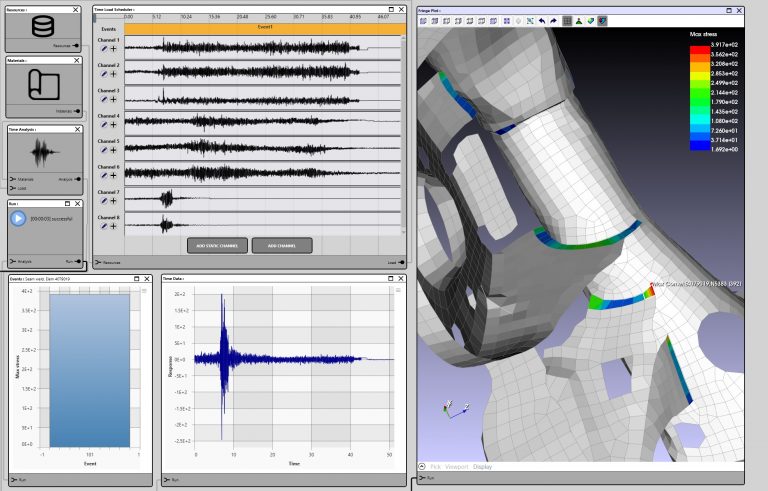

CAEfatigue is designed to provide basic fatigue analysis tools for the linear static superposition approach, the modal participation factor approach and the direct stress recovery method. This TIME package is intended to provide a vast improvement in the analysis process for conventional static superposition analysis, modal participation factor (dynamic transient) analysis and direct stress recovery analysis. The TIME package uses state of the art software development tools and algorithms to deliver a fatigue solver with superior speed and accuracy. Coupling time domain tools with frequency domain tools provides Customers with a complete time and frequency domain analysis package that surpasses the performance and accuracy needs of our users.

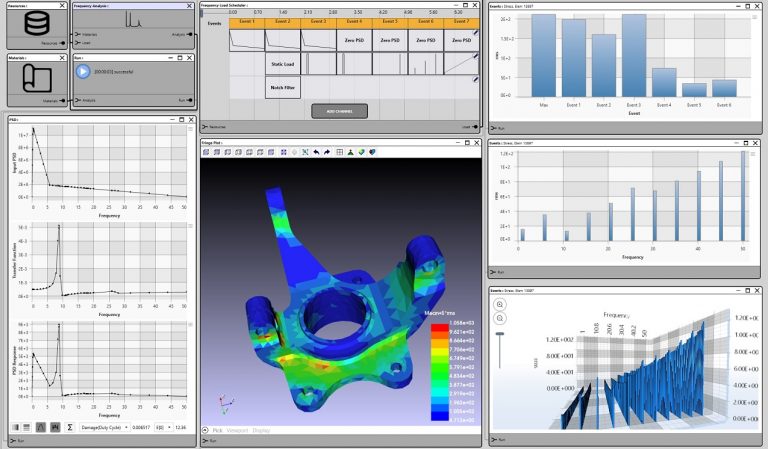

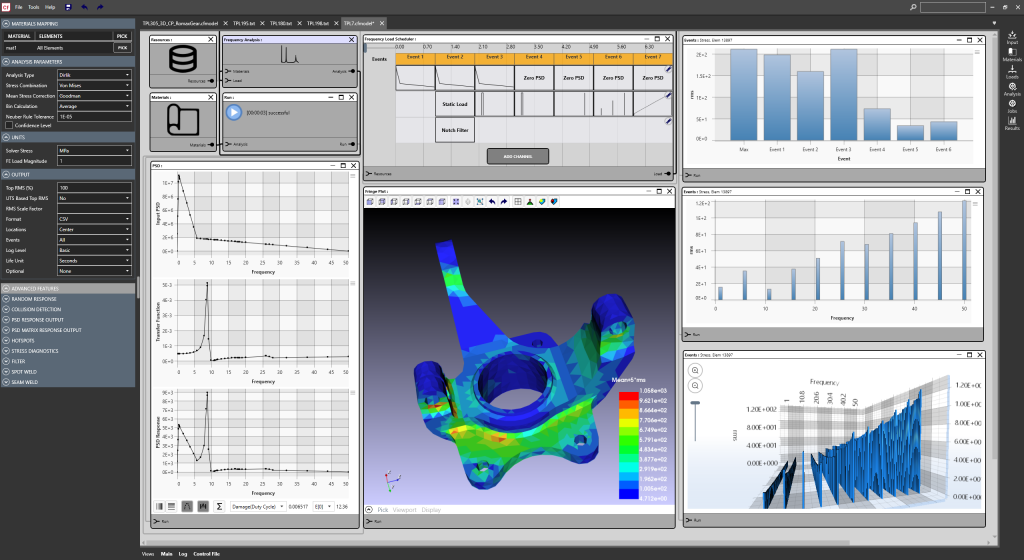

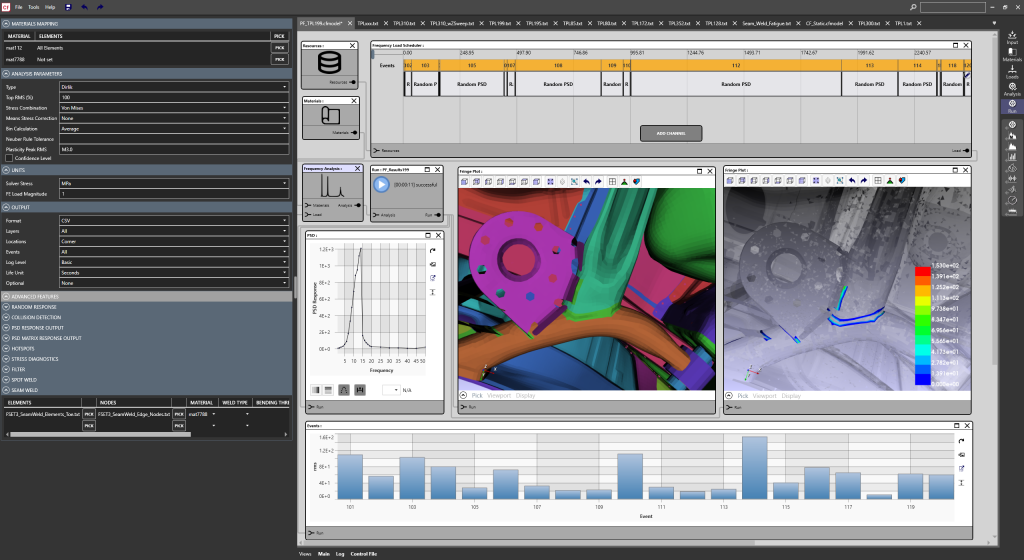

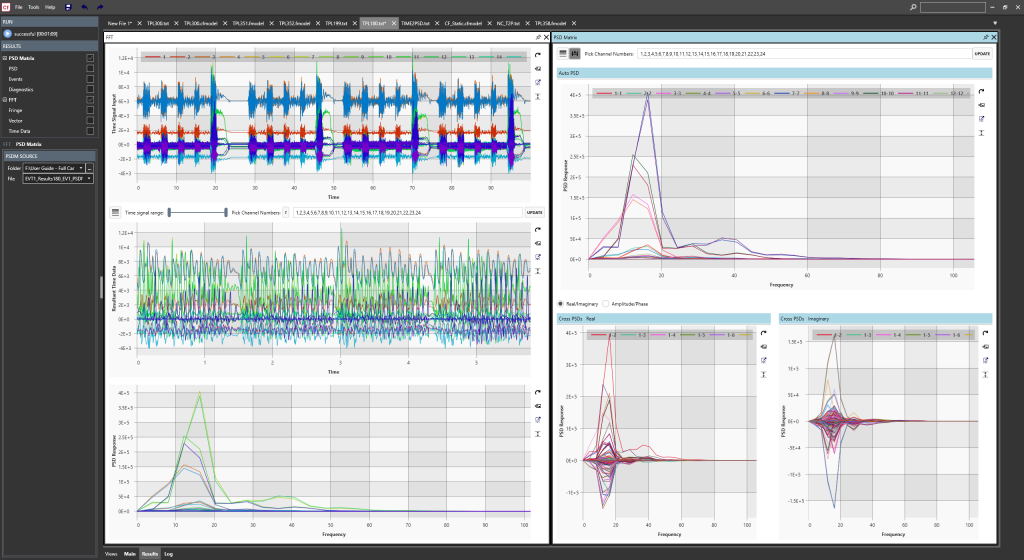

Multi Input PSD Analysis for Multi-Channel, Multi-Event Loading

CAEfatigue offers all the input / output options mentioned for Base Shake loading plus the ability to use multiple random input PSDs (and cross PSDs) with mean offsets; i.e., data from a test rig with multiple events and multiple channels per event plus a mean offset. This module offers random response and S-N and/or E-N fatigue results generated from the multiple simultaneous correlated load inputs, with any number of DOF’s, inputs, events and frequencies. Coupled with advanced random analysis, CF becomes a powerful tool for understanding output results for displacement, velocity, acceleration, force, stress, strain and fatigue (damage / life).

Base Shake PSD Analysis plus Mean Loads plus Deterministic Loading

CAEfatigue is designed to provide the user with both the random response results and the fatigue results from a structure undergoing loading input from a single random PSD with or without additional loading from deterministic inputs and mean offsets. This package allows the User to do Random Analysis only. Response outputs includes mean stress, RMS stress or strain, mean stress plus RMS stress or strain, moments, zero crossings, peaks per second and irregularity factor.

The loading inputs needed for CF can come from Optistruct, Nastran, Ansys or Abaqus generated from (virtually) any size model. Examples of inputs are simultaneous wide band and narrow band inputs, wide band random and swept sine inputs, wide band random and deterministic inputs, wide band and swept narrow band inputs, swept narrow band or swept sine wave.

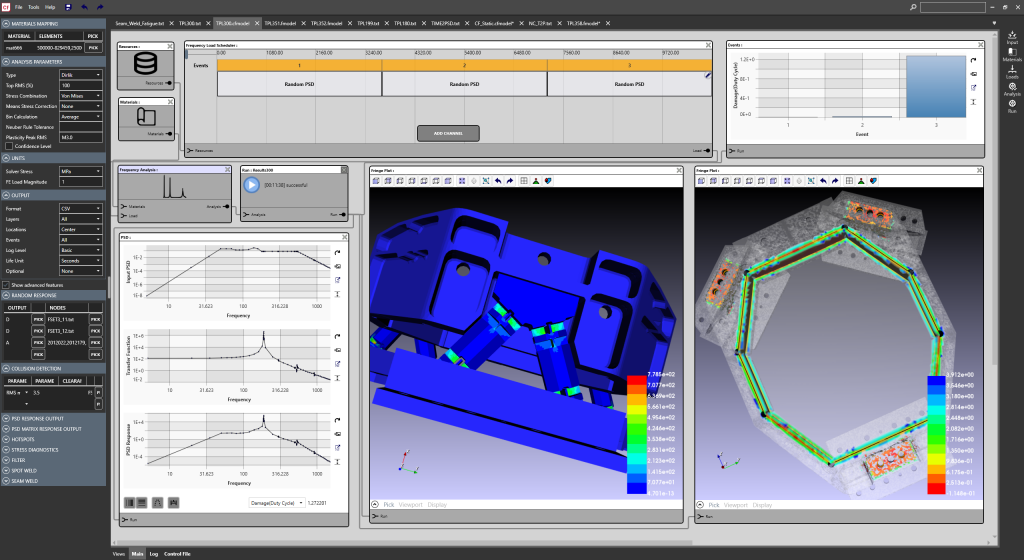

Advanced Random Analysis

For many automotive and aerospace systems it is required to calculate both durability and to rule out the possibility of collision of individual components during severe base shake vibration conditions. Advanced frequency domain methods now exist to enable the durability assessment and response to be assessed in the same analysis. With the advanced random analysis output, it is possible to output displacement and/or velocity and/or acceleration and/or force RMS levels and Power Spectral Density (PSD) plots for both absolute and relative responses. In addition, a residual sum of the squares (RSS) is calculated to take into account any off axis response.

New post processing options allow the relative response from any node to be compared against the actual distance to all nearby nodes in order to check for the probability of collisions (i.e. RATTLE) between adjacent parts. The response maximum is determined using either a ratio of the RMS (e.g. 3.0*rms) from a corresponding level of probability on a Gaussian or Rayleigh distribution, or by using a method which takes into account the number of cycles of response. Advanced Random Analysis output is an excellent addition to predict structural response under complicated loading conditions found in many engineering applications throughout a wide variety of industries.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae(Simufact, Digimat, Nastran, MSC APEX, Actran Acoustic solver), ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Creep and Creep-Fatigue Interactions

considering Creep-Fatigue interaction in high temperature simulations identifies whether fatigue and/or creep are the dominant damaging mechanisms, thus allowing re-design to focus on the relevant damage mechanisms and significantly reduce pre-service component testing.

Read more... Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Structural vibration can be a source for many product related problems; it can cause fatigue and durability problems as well as adverse reactions to the user or bystanders in the form of undesirable vibrations that can be felt or heard. As well, undesired structural vibrations can prevent products from operating as required and potentially becoming a safety concern. The Vibration Fatigue simulation predict fatigue in the frequency domain and it is more realistic and efficient than time-domain analysis for many applications with random loading such as wind and wave loads.

Read more... Fatigue Analysis of Welded Structures Using the Finite Element Method

Enteknograte use advanced Numerical simulation software and methods to simulate the welding behavior in real service load condition and estimate its Durability and Fatigue Life with Ansys Ncode, Simulia FE-Safe, MSC CAEFatigue and FEMFAT. The Seam Weld and Spot Weld fatigue simulation enables the fatigue analysis of joints including different type of welding such as fillet, overlap, spot welds in thin sheets and laser welded joints.

Read more... Finite Element Analysis of Durability and Fatigue Life

Vibration Fatigue, Creep, Welded Structures Fatigue, Elastomer and Composite Fatigue with Ansys Ncode, Simulia FE-Safe, MSC CAEFatigue, FEMFAT

Durability often dominates development agendas, and empirical evaluation is by its nature time-consuming and costly. Simulation provides a strategic approach to managing risk and cost by enabling design concepts or design changes to be studied before investment in physical evaluation. The industry-leading fatigue Simulation technology such as Simulia FE-SAFE, Ansys Ncode Design Life and FEMFAT used to calculate fatigue life of multiaxial, welds, short-fibre composite, vibration, crack growth, thermo-mechanical fatigue.

Read more... Elastomer Materials Fatigue Finite Element Analysis

Developers of rubber materials, components and systems increasingly rely on simulation as a routine means to address design issues. For metallic components, solutions for fatigue analysis from FEA have existed commercially for many years and have become an essential part of maturing and qualifying design concepts in many industrial sectors. Using modern multiaxial strain based fatigue methods enable us to simulate the fatigue analysis of elastomer materials and Rubber.

Read more... Composites Fatigue Finite Element Simulation

The structural durability of a component is one of the most expensive attributes to test, thus one of the most appealing for CAE. Fatigue modeling of chopped and continuous fiber polymer composites is challenging due to their anisotropic, heterogeneous and viscous material properties as well as their process-dependent microstructure. For simulation of high cycle fatigue (HCF) of fiber reinforced composites we use FEA tools Like VirtualLab Durability, nCode DesignLife , MSC CAEFatigue and FE-SAFE.

Read more... Additive Manufacturing and 3D Printing

FEA Based Design and Optimization with Simufact, Abaqus, ANSYS and MSC Apex for powder bed fusion (PBF), directed energy deposition (DED) and binder jetting processes

With additive manufacturing, the design is not constrained by traditional manufacturing requirements and specific number of design parameters. Nonparametric optimization with new technologies such as Artificial Intelligence in coupled with Finite Element method, can be used to produce functional designs with the least amount of material. Additive manufacturing simulations are key in assessing a finished part’s quality. Here at Eneteknograte, dependent of the problem detail, we use advanced tools such as MSC Apex Generative Design, Simufact Additive, Digimat, Abaqus and Ansys.

Read more... Thermal Stress and Fatigue Simulation: Coupled CFD and Finite Element Approach

Enteknograte’s Engineering Team provides a comprehensive Steady-State and Transient CFD Thermal Analysis & Design services using MSC Cradle, Siemens Star-ccm+, OpenFoam and Ansys Fluent Flow Simulation. CFD Thermal Analysis extends the capability of FEA thermal analysis with MSC Nastran, Abaqus and LS-Dyna by replacing the simplistic convection boundary conditions with direct calculations of the heat transfer coefficients based on the fluid flow properties and is often referred to a conjugate heat transfer analysis.

Read more... Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Transient Resistance, Propulsion, Sea-Keeping and Maneuvering Simulation, Cavitation, Vibration and Fatigue

Hydrodynamics is a common application of CFD and a main core of Enteknograte expertise for ship, boat, yacht, marine and offshore structures simulation based design. Coupling Hydrodynamic CFD Simulation in Ansys Fluent, Siemens Star-ccm+ and MSC Cradle with structural finite element solver such as Abaqus and Ansys, enable us to Simulate most complicated industrial problem such as Cavitation, Vibration and Fatigue induced by hydrodynamics fluctuation, Transient Resistance, Propulsion, Sea-Keeping and Maneuvering Simulation, considering two way FSI (Fluid Structure Interaction) coupling technology.

Read more... Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Machine learning is a method of data analysis that automates analytical model building. It is a branch of Artificial Intelligence based on the idea that systems can learn from data, identify patterns and make decisions with minimal human intervention. With Artificial Intelligence (AI) applications in CAE, that is Mechanical Engineering and FEA and CFD Simulations as design tools, our CAE engineers evaluate the possible changes (and limits) coming from Machine learning, whether Deep Learning (DL), or Support vector machine (SVM) or even Genetic algorithms to specify definitive influence in some optimization problems and the solution of complex systems.

Read more... Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Noise and vibration analysis is becoming increasingly important in virtually every industry. The need to reduce noise and vibration can arise because of government legislation, new lightweight constructions, use of lower cost materials, fatigue failure or increased competitive pressure. With deep knowledge in FEA, CFD and Acoustic simulation, advanced Acoustic solvers and numerical methods used by Enteknograte engineers to solve acoustics, vibro-acoustics, and aero-acoustics problems in automotive manufacturers and suppliers, aerospace companies, shipbuilding industries and consumer product manufacturers.

Read more... Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

We analyze system-level thermal management of vehicle component, including underhood, underbody and brake systems, and design for heat shields, electronics cooling, HVAC, hybrid systems and human thermal comfort. Our Finite Element (LS-Dyna, Ansys, Abaqus) and CFD simulation (Siemens Start-ccm+, Ansys Fluent , Ansys CFX and OpenFoam) for heat transfer analysis, thermal management, and virtual test process can save time and money in the design and development process, while also improving the thermal comfort and overall quality of the final product.

Read more... Multibody Dynamics

Robots Dynamics, Control Systems, Advanced Machinery, Full Vehicle MBD and NVH

Multibody dynamic analysis is important because product design frequently requires an understanding of how multiple moving parts interact with each other and their environment. From automobiles and aircraft to washing machines and assembly lines - moving parts generate loads that are often difficult to predict. Complex mechanical assemblies present design challenges that require a dynamic system-level analysis to be met. Accurate modeling can require representations of various types of components, like electronic controls systems and compliant parts and connections, as well as complicated physical phenomena like vibration, friction and noise.

Read more... Finite Element Simulation of Crash Test and Crashworthiness with LS-Dyna, Abaqus and PAM-CRASH

Crashworthiness focuses on occupant protection to reduce the number of fatal and serious injuries. This research is responsible for developing and upgrading test procedures for evaluating motor vehicle safety. Crashworthiness research encompasses new and improved vehicle design, safety countermeasures and equipment to enhance occupant safety.

Finite Element Analysis (FEA) has been the trend in virtual crash design over the last decade. The predictive capabilities of FEA allow engineers to fully understand a crash event in a virtual environment, thus limiting the number of physical tests that need to be executed and thus saving costs.

Read more... Previous

Next