- Aerospace Engineering: AeroAcoustics and VibroAcoustics

- Automotive Industry: AeroAcoustics and VibroAcoustics design

- Hybrid & Electric Vehicles: NVH & Acoustics

- Shipbuilding Acoustics and VibroAcoustics Engineering

- Audio & Consumer Electronic Devices Design

- NVH ( Noise, Vibration, and Harshness ) simulation services

Acoustics and Vibration Simulation: FEA & CFD for AeroAcoustics, VibroAcoustics and NVH Analysis in Automotive, Aerospace, Shipbuilding and Consumer Product Manufacturers.

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

Noise and vibration analysis is becoming increasingly important in virtually every industry. The need to reduce noise and vibration can arise because of government legislation, new lightweight constructions, use of lower cost materials, fatigue failure or increased competitive pressure. With deep knowledge in FEA, CFD and Acoustic simulation, advanced Acoustic solvers and numerical methods used by Enteknograte engineers to solve acoustics, vibro-acoustics, and aero-acoustics problems in automotive manufacturers and suppliers, aerospace companies, shipbuilding industries and consumer product manufacturers.

Simulation-Based Design for better understand and improve the acoustics performance of your designs:

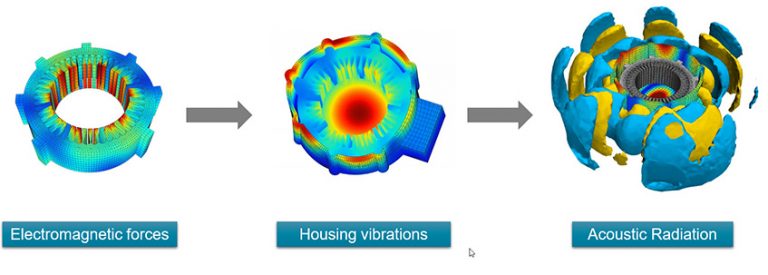

- Sound radiation by vibrating structures: powertrain, engine components (intake manifold and air filter, valve cover, etc.), compressors, electrical motors, loudspeakers.

- Intake and exhaust noise, including complex mufflers and silencers.

- Air conditioning units and distribution systems.

- Sound absorption inside passenger compartment of cars and trains.

- Sound propagation in complex media with mean flow or temperature gradient.

- Audio devices such as telephones, hearing aids or musical instruments.

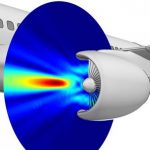

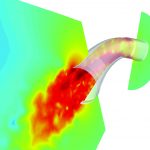

AeroAcoustics

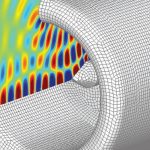

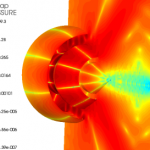

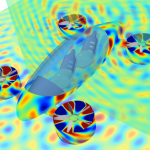

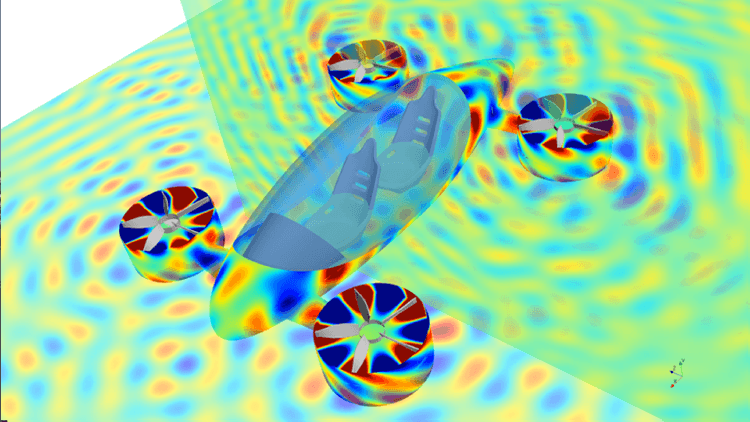

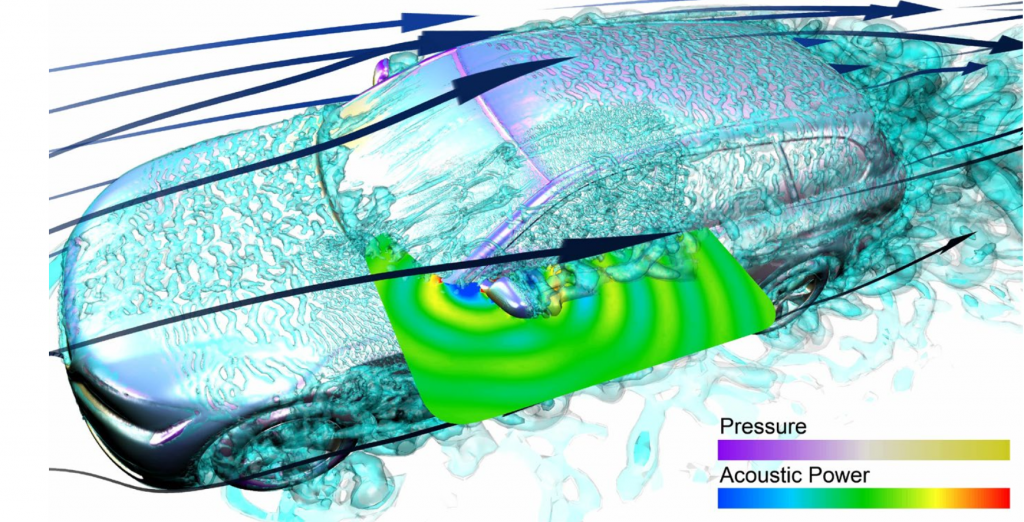

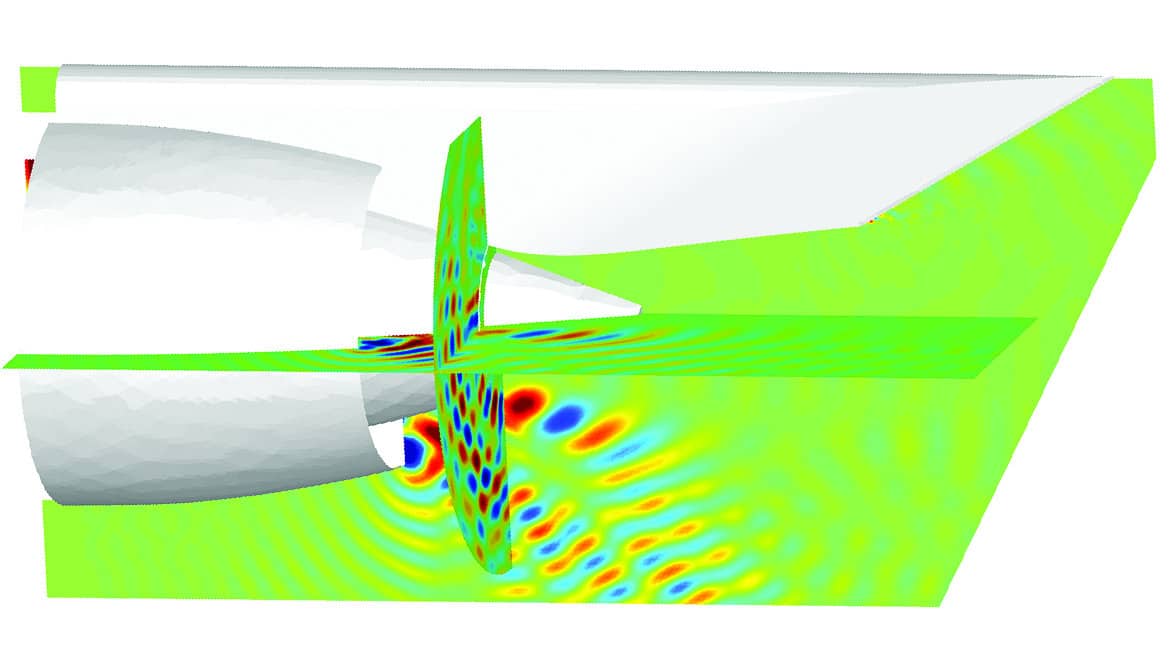

AeroAcoustics simulation try to use advanced capabilities with couple using of CFD simulation and advanced Acoustic solvers to predict accurately and efficiently the noise generated by turbulent flows. Results from an unsteady flow simulation performed with CFD codes such as Ansys Fluent, StarCCM+, Numeca, AVL FIRE M, OpenFOAM and others are used by AeroAcoustics solver to compute aerodynamic noise sources.

With using AeroAcoustics simulation, our engineers can study the noise generated by any turbulent flow and the interactions between the aeroacoustic noise sources and a vibrating structure, absorbant materials or acoustic traps such as resonators.

Applications:

- Air conditioning modules (HVAC).

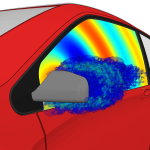

- Side mirror noise.

- Airframe noise (landing gear, trailing edge).

- Air distribution systems.

- Fan Noise

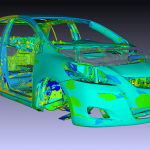

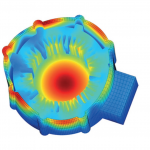

VibroAcoustics

In order to study the interaction of structural vibration with the fluid, it is necessary to model the acoustic behavior of the involved structural components including the conventional material for acoustic or visco-elastic media, porous or incompressible media, composite materials or active components like piezo-electric ceramics.

Applications:

- Automotive: Noise related problems from powertrains, intakes, exhausts, passenger compartment, trim, seats, hoses, tires, windows and windshields, audio, HVAC.

- Aerospace: Sound transmission through cockpit and fuselage, noise propagation in air distribution system, random dynamic response at take-off.

- Consumer goods: Telephones, headsets, loudspeakers, hearing aid devices, disk drives, washing machines, refrigerators, cameras

Boundary Element Acoustics

Often used for exterior acoustics problems, the boundary element method (BEM) is ideal for problems involving very complex geometry that may be a challenge to model for the FEM method. The BEM method helps simplify exterior acoustics simulation since only the outer surface mesh of the geometry is needed. This simplifies both the modeling process and reduces the degrees of freedom in the simulation model which will result in easier analysis.

Finite Element Acoustics

The finite element method (FEM) for acoustics analysis is ideal for simulating interior acoustics problems. In addition to FEM being the more efficient method in terms of solution speed, FEM acoustics lets you perform coupled vibro-acoustics analyses that take structural modes and soundproofing materials into consideration. FEM acoustics can be used to solve exterior acoustics problems as well, which is often used for noise analysis of air induction systems in powertrain.

NVH based Design and Considerations

The challenge for the NVH specialists is to support the concept and design development process by reliable recommendations just-in-time prior concept or design freeze. Enteknograte’s specialists particularly use advanced methodologies for NVH simulation and optimization:

- FEA based Powertrain

- Structural Optimization

- Optimization of Engine Dynamics based on MBD ( Multi-Body Dynamics Simulation)

- Concurrent optimization of combustion efficiency with NVH considerations

- Vehicle Interior Noise Simulation based on measurement and CAE

- Vehicle Exterior Noise Simulation with couple use of CFD and FEA solvers

- Objective Analysis of Sound Quality

- VTOL, e-VTOL and UAM – Urban Air Mobility systems noise and comfort

Aerospace Engineering: AeroAcoustics and VibroAcoustics Simulation

AeroAcoustics and VibroAcoustics in Automotive Industry

NVH & Acoustics for Hybrid & Electric Vehicles

Structural Dynamics Integrity & Vibro-Acoustics Simulation for Marine & Shipbuilding Industry

Audio Device Design: Acoustic simulation for Sound Quality Analysis in Consumer Electronic Devices

NVH ( Noise, Vibration, and Harshness ) simulation services

Finite Element Analysis of Durability and Fatigue Life

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Hydrodynamics & HydroAcoustics simulation for AIV (Acoustic Induced Vibration)

Cavitation in Propulsion Systems

Multibody Dynamics & NVH (Noise, vibration, and harshness)

Noise, Vibration & Harshness – NVH for Electric Motors

Enteknograte offers a Virtual Engineering approach with CFD and FEA tools such as MSC Cradle, Ansys Fluent, StarCCM+ for flows simulation and FEA based Codes such as ABAQUS, Ansys, Nastran and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components. Dependent of problem, we use ESI VA-one and MSC Actran as acoustics solver

Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Seat Design: Finite Element and CFD Simulation for Static & Dynamic Comfort, Whiplash, Acoustic & Thermal Comfort, Crash Test

1D/3D Coupled Simulation and Co-Simulation: Detailed Chemistry & Multiphase Flow Modeling with 1D Modeling

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation

eVTOL (Electric Vertical Take-Off and Landing) & UAM (Urban Air Mobility)

Full Vehicle MultiBody Dynamics Simulation: Car Ride, Driveline, Engine and Tire MBD

Robots Dynamics & Performance Assessment: Coupled MBD & FEA Simulation-Based Design

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Aerodynamic Noise Simulation

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Electromagnetic Multiphysics