MSC Actran: Advanced Acoustics, Aero-Acoustics and Vibro-Acoustics Solver

Actran is the premier acoustic simulation software to solve acoustics, vibro-acoustics, and aero-acoustics problems. Used by automotive manufacturers and suppliers, aerospace and defense companies, and consumer product manufacturers, Actran helps engineers better understand and improve the acoustics performance of their designs.

Actran VibroAcoustics

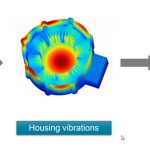

In order to study the interaction of structural vibration with the adjacent fluid, it is necessary to model the acoustic behavior of the involved structural components. This can be achieved with the rich material library of Actran, that includes the conventional material for acoustic or visco-elastic media, porous or incompressible media, hydroacoustics, composite materials or active components like piezo-electric ceramics. If you prefer, a modal basis of the structure may also be imported from most structural FEA codes.

With the ability to simulate realistic modeling boundary conditions by combining dynamic, kinematic and acoustic constraints, as well as physical excitations like diffuse sound field and turbulent boundary layer, you can obtain accurate representation of the acoustic performance of your designs. In addition, you also have the ability to combine this capability with Actran AeroAcoustics to giving you the ability to model complex aero-vibro-acoustic problems.

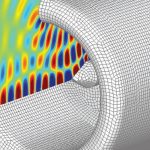

Actran AeroAcoustics

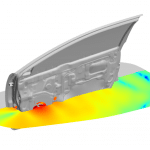

Actran AeroAcoustics is a module featuring advanced capabilities to predict accurately and efficiently the noise generated by turbulent flows. Results from an unsteady flow simulation performed with CFD codes such as scFLOWTM and SC/TetraTM (but also FluentTM, Star-CDTM, StarCCM+TM, PowerflowTM, OpenFOAMTM and others) are used by Actran AeroAcoustics to compute aerodynamic noise sources. The acoustic propagation from these aerodynamic sources is then computed to provide users with acoustic results such as noise levels and directivity.

Using Actran AeroAcoustics, the noise generated by any turbulent flow can be thoroughly predicted. Users can benefit from all features of the Actran software suite to study the interactions between the aeroacoustic noise sources and a vibrating structure, absorbant materials or acoustic traps such as resonators.

Actran SNGR

Predicting the noise generated by complex flows from steady CFD solutions

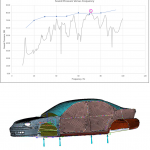

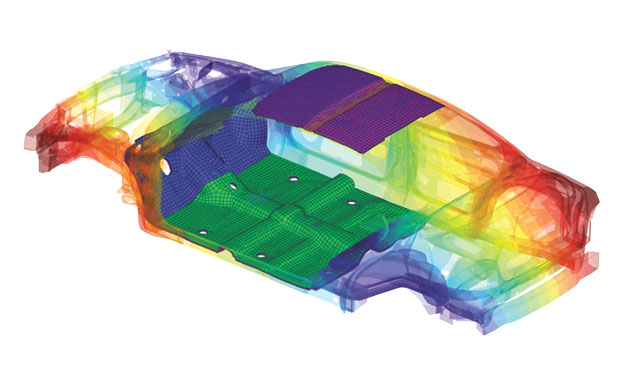

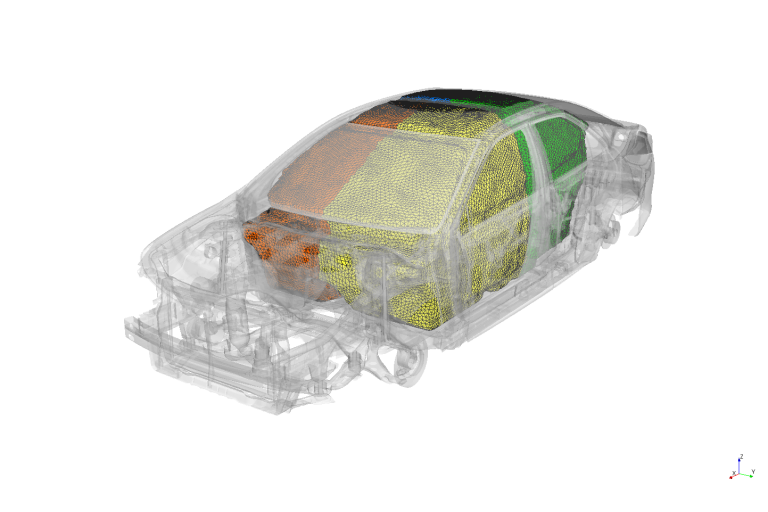

Actran for Trimmed Body

Advanced vibro-acoustic analysis

Actran for Trimmed Bodies is a powerful tool for modeling and analyzing complex vibro-acoustic systems such as trim components. Such components are usually made of materials with high damping and strong acoustic absorption characteristics; as such they have a significant influence on the overall vibro-acoustic behavior of the structure.

Actran for Trimmed Bodies provides CAE engineers advanced features for mixing the best of both worlds: Actran physical model and Nastran modal model. Three types of combined models may be created:

- Actran for Trimmed Bodies is able to merge a set of Actran models of individual trim components with a Nastran body-in-white model in order to create a fully trimmed body vibro-acoustic model.

- An Actran model may be set in its real-life working environment by connecting it to an existing Nastran model (e.g. a detailed Actran model of a layered windshield may be connected to a Nastran model of the vehicle body).

- A Nastran model may be enriched by including a reduced Actran model of a specific component. The Actran component is defined as a DMIG data block in the Nastran deck.

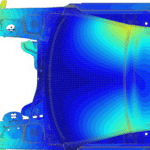

Actran SEA

Statistical Energy Analysis approach offers an effcient solution to study noise and vibration propagation inside large systems at mid- and high-frequencies. The global system is reduced to a set of coupled subsystems and energy balance between them is computed. Building a SEA model with classical approaches usually requires an access to experimental data or analytical expressions limiting the range of geometrical objects that could be handled. With Actran SEA module and its Virtual SEA approach, CAE engineers can use their existing Finite Elements vibro-acoustic models (mode shape and eigen values) to create a SEA model.

Based on automatic or user-defined subsystems definition, SEA parameters are efficiently extracted from the Finite Elements model to perform sound and vibration analysis at mid- and high frequencies together with transfer path analysis regardless the availability of SEA expertise or experimental-based information. Combined with a unique frequency extrapolation method, the Actran SEA module offers the possibility to extend the frequency range validity of existing vibro-acoustic finite elements models to high frequency analysis.

Actran DGM

High performing acoustic propagation modeling

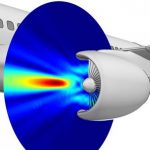

Actran DGM solves the linearized Euler equations using discontinuous finite elements and is used for predicting the noise propagation in complex physical conditions. It is particularly well suited to solving aero-acoustic problems at the exhaust of a double flux aero-engine, including effects such as propagation through strong shear layers, high temperature gradients and non-homentropic mean flows.

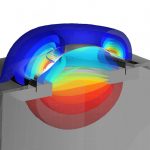

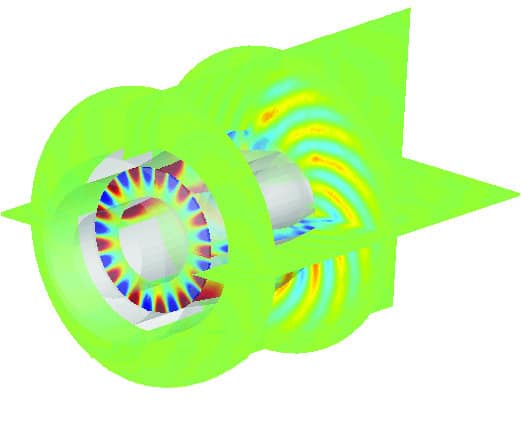

Actran TM

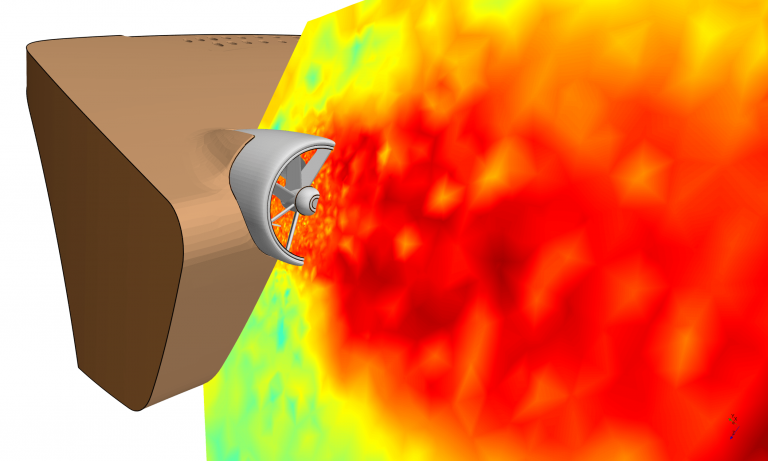

A powerful acoustic CAE tool for turbomachinery noise prediction

Use Actran TM to analyze the sound radiated by turbomachinery and to optimize the related acoustic treatments. One of the challenges of acoustic CAE methods is handling of large models associated to high wave number and to large geometrical size and complexity. Actran TM provides efficient solver technologies to address this problem, which includes advanced parallel processing.

In addition to studying aircraft engines, Actran TM can be used to analyze inlet and outlet liners for helicopter turbines, environmental control systems, and auxiliary power units, and for non-aerospace applications like computer cooling systems. Actran TM can be complemented by Actran DGM to solve problems involving complex shear layers and flow gradients occurring at engine exhaust.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae(Simufact, Digimat, Nastran, MSC APEX, Actran Acoustic solver), ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Aerospace Engineering: AeroAcoustics and VibroAcoustics Simulation

AeroAcoustics and VibroAcoustics in Automotive Industry

NVH & Acoustics for Hybrid & Electric Vehicles

Structural Dynamics Integrity & Vibro-Acoustics Simulation for Marine & Shipbuilding Industry

Audio Device Design: Acoustic simulation for Sound Quality Analysis in Consumer Electronic Devices

NVH ( Noise, Vibration, and Harshness ) simulation services

Finite Element Analysis of Durability and Fatigue Life

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Hydrodynamics & HydroAcoustics simulation for AIV (Acoustic Induced Vibration)

Cavitation in Propulsion Systems

Multibody Dynamics & NVH (Noise, vibration, and harshness)

Noise, Vibration & Harshness – NVH for Electric Motors

Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Seat Design: Finite Element and CFD Simulation for Static & Dynamic Comfort, Whiplash, Acoustic & Thermal Comfort, Crash Test

1D/3D Coupled Simulation and Co-Simulation: Detailed Chemistry & Multiphase Flow Modeling with 1D Modeling

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation

eVTOL (Electric Vertical Take-Off and Landing) & UAM (Urban Air Mobility)

Full Vehicle MultiBody Dynamics Simulation: Car Ride, Driveline, Engine and Tire MBD

Robots Dynamics & Performance Assessment: Coupled MBD & FEA Simulation-Based Design

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Aerodynamic Noise Simulation

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Electromagnetic Multiphysics

CFD and FEA in Civil Engineering: Seismic Design, Earthquake, Tunnel, Dam, Concrete Structures and Geotechnical Multiphysics Simulation

Marine and Shipbuilding Industry: Finite Element and CFD Based Simulation and Design

In Silico Medical & Biomedical Device Testing: Finite Element & CFD Simulation and Design, Considering FDA & ASME V&V 40

FEA and CFD Simulation for Aerospace Structures: Aerodynamics, Acoustics, Fatigue and Vibration, Thermal Analysis, Crash & Impact