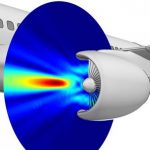

- Aerospace Engineering: AeroAcoustics and VibroAcoustics

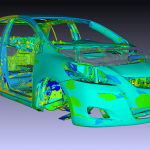

- Automotive Industry: AeroAcoustics and VibroAcoustics design

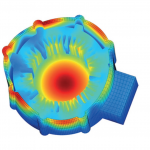

- Hybrid & Electric Vehicles: NVH & Acoustics

- Shipbuilding Acoustics and VibroAcoustics Engineering

- Audio & Consumer Electronic Devices Design

- NVH ( Noise, Vibration, and Harshness ) simulation services

NVH ( Noise, Vibration, and Harshness ) simulation services

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

Excellent NVH has become a vital machine and vehicle development target as it contributes to product quality and customer satisfaction. Advanced NVH experimental and virtual tools are prerequisites for cost and time effective development minimizing pre-production troubleshooting effort and shortening time-to-market. Our scope of work ranges from NVH benchmark and target setting, troubleshooting, sound design, low noise powertrain and driveline development, NVH engineering within machine and vehicle integration up to full machine NVH development responsibility.

Interior noise is that heard inside the cabin by the occupants of the vehicle while external noise is that heard by those outside of the vehicle, for example pedestrians at the roadside. Interestingly enough, while noise and vibration can both be objectively measured, harshness is a more subjective quality. This produces a challenging problem for noise, vibration, and harshness simulation software. Besides passenger cars the field of our NVH activities covers also trucks as well as off-road and industrial machinery

For an early design of NVH characteristics of components and entire machine and vehicle, simulation tools are essential. Enteknograte offers a wide variety of solutions to your questions concerning the simulation of sound and vibrations. Be it the analytical modeling of possible noise sources under consideration of their physical formation mechanisms or FE and MBD models for the simulation of sound and vibration transfer – we are prepared for all of your questions.

Enteknograte’s NVH expertise includes:

- Engine and transmission NVH

- Body acoustics

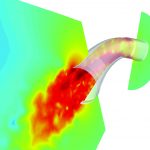

- Aeroacoustics

- Power train induced NVH

- Road NVH

- Sound design and sound quality

- Squeak and Rattle

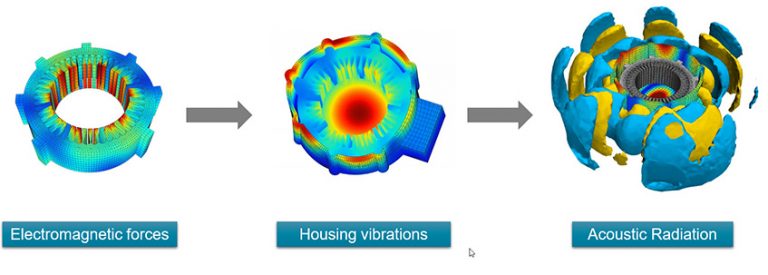

- Component induced NVH

NVH based Design and Considerations

The challenge for the NVH specialists is to support the concept and design development process by reliable recommendations just-in-time prior concept or design freeze. Enteknograte’s specialists particularly use advanced methodologies for NVH simulation and optimization:

- FEA based Powertrain

- Structural Optimization

- Optimization of Engine Dynamics based on MBD ( Multi-Body Dynamics Simulation)

- Concurrent optimization of combustion efficiency with NVH considerations

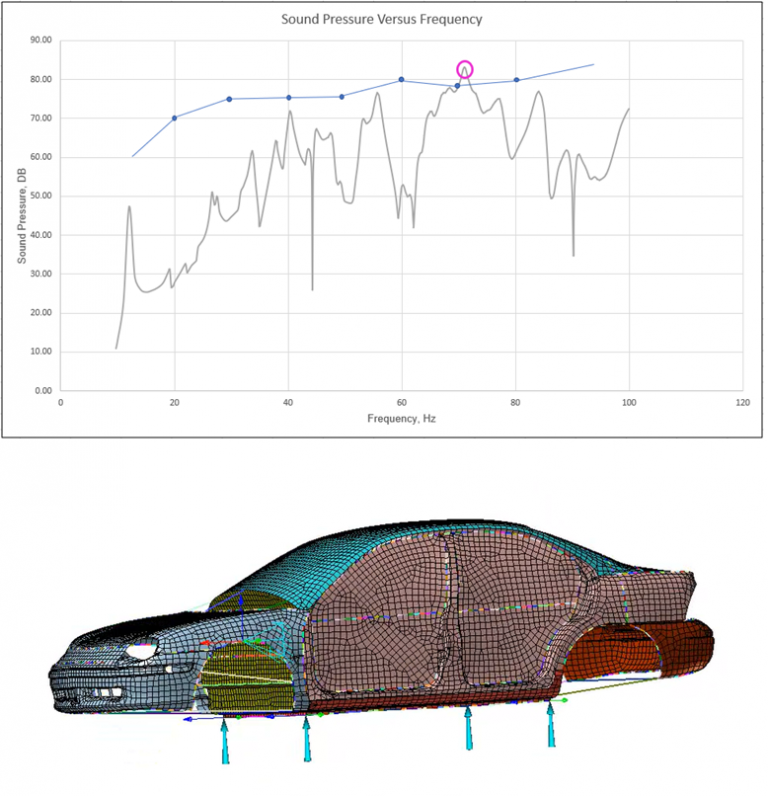

- Vehicle Interior Noise Simulation based on measurement and CAE

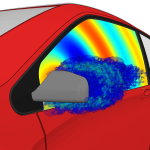

- Vehicle Exterior Noise Simulation with couple use of CFD and FEA solvers

- Objective Analysis of Sound Quality

Enteknograte offers a Virtual Engineering approach with CFD and FEA tools such as Ansys Fluent, StarCCM+ for flows simulation and FEA based Codes such as ABAQUS, Ansys, Nastran and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components. Dependent of problem, we use ESI VA-one and MSC Actran as acoustics solver

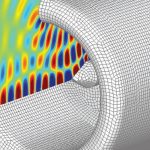

Boundary Element Acoustics

Often used for exterior acoustics problems, the boundary element method (BEM) is ideal for problems involving very complex geometry that may be a challenge to model for the FEM method. The BEM method helps simplify exterior acoustics simulation since only the outer surface mesh of the geometry is needed. This simplifies both the modeling process and reduces the degrees of freedom in the simulation model which will result in easier analysis.

Finite Element Acoustics

The finite element method (FEM) for acoustics analysis is ideal for simulating interior acoustics problems. In addition to FEM being the more efficient method in terms of solution speed, FEM acoustics lets you perform coupled vibro-acoustics analyses that take structural modes and soundproofing materials into consideration. FEM acoustics can be used to solve exterior acoustics problems as well, which is often used for noise analysis of air induction systems in powertrain.

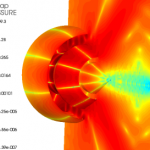

Aerospace Engineering: AeroAcoustics and VibroAcoustics Simulation

AeroAcoustics and VibroAcoustics in Automotive Industry

NVH & Acoustics for Hybrid & Electric Vehicles

Structural Dynamics Integrity & Vibro-Acoustics Simulation for Marine & Shipbuilding Industry

Audio Device Design: Acoustic simulation for Sound Quality Analysis in Consumer Electronic Devices

NVH ( Noise, Vibration, and Harshness ) simulation services

Finite Element Analysis of Durability and Fatigue Life

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Hydrodynamics & HydroAcoustics simulation for AIV (Acoustic Induced Vibration)

Cavitation in Propulsion Systems

Multibody Dynamics & NVH (Noise, vibration, and harshness)

Noise, Vibration & Harshness – NVH for Electric Motors

Enteknograte offers a Virtual Engineering approach with CFD and FEA tools such as MSC Cradle, Ansys Fluent, StarCCM+ for flows simulation and FEA based Codes such as ABAQUS, Ansys, Nastran and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components. Dependent of problem, we use ESI VA-one and MSC Actran as acoustics solver

Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Seat Design: Finite Element and CFD Simulation for Static & Dynamic Comfort, Whiplash, Acoustic & Thermal Comfort, Crash Test

1D/3D Coupled Simulation and Co-Simulation: Detailed Chemistry & Multiphase Flow Modeling with 1D Modeling

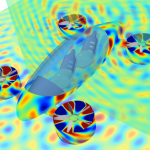

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation

eVTOL (Electric Vertical Take-Off and Landing) & UAM (Urban Air Mobility)

Full Vehicle MultiBody Dynamics Simulation: Car Ride, Driveline, Engine and Tire MBD

Robots Dynamics & Performance Assessment: Coupled MBD & FEA Simulation-Based Design

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Aerodynamic Noise Simulation

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Electromagnetic Multiphysics