Finite Element Simulation of Braided Composites

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

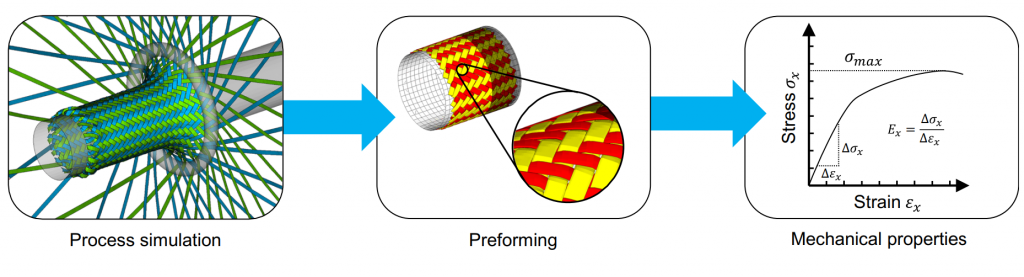

With braided composites, the reinforcement does not need to be cut to shape from a roll and laid down onto the mold. It is directly braided around a mandrel which has the shape of the part to be made. This speeds up the manufacturing process but requires a dedicated equipment. This process further makes it possible to produce more complex parts which, however, are limited to convex shapes and hollow profiles.

Enteknograte have strong capabilities for the designing and simulation of braided composite materials and structures using combination of advanced FEA and optimization tools based on advanced models which are capable of considering the underlying yarn structure and braiding pattern including yarns going across multiple layers and inlays.

Just as for the woven composites, material modeling can be performed fully nonlinear, temperature and strain rate dependent. Failure is derived from the microscopic responses in the material resulting in a realistic description of the experimentally observed strengths.

What Enteknograte do with FEA Based Simulation Design in Composite Material Engineering:

- Multi-scale analyses to predict the nonlinear microstructure behavior of plastic & composite materials & structures

- Speeds up the development process for composite materials and structures

- Perform detailed analyses of materials on the microstructure level

- Derive microstructure material models suited for multi-scale coupling of the micro- and macroscopic level

- Bridges the gap between manufacturing and performance

- Understand Thermal, Thermo-Mechanical and Electrical behaviour of New Material

- Crash Performance simulation

- Fatigue and Creep assessment of Composite and New Material

- Acoustic and Vibration analysis before Manufacturing

- Stiffness and Strength properties

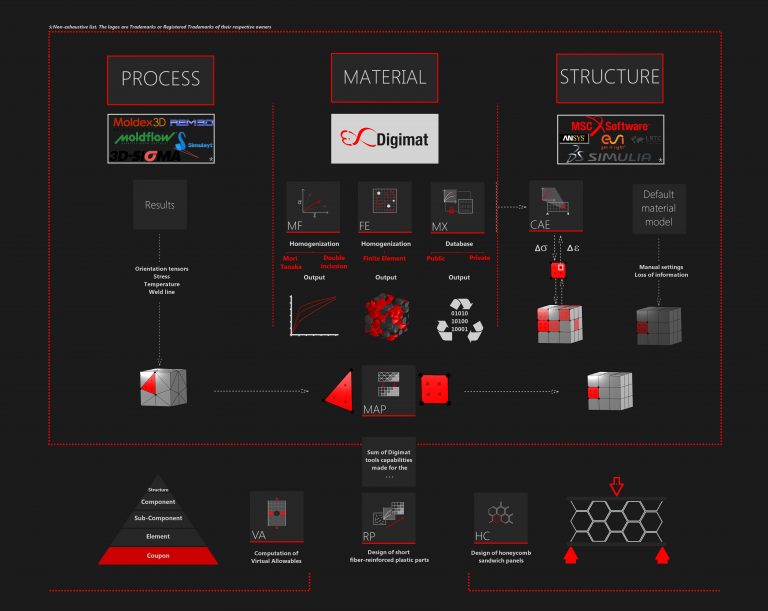

- Process simulation: Injection and compression molding, drape molding, RTM, etc.

- Industries: Aerospace, Automotive, Consumer Electronics, Material Suppliers, etc.

CAE softwares: MSC software (Digimat, Marc, Nastran), Abaqus, Altair, ANSYS, Autodesk Moldflow, LS-Dyna, PAM-CRASH, RADIOSS and SAMCEF.

Finite element simulation of woven fabric composites

Woven composites are typically draped onto more or less complex surfaces to produce structural parts. The overall objective is to use light-weight materials with the best stiffness and strength properties possible. The draping process can have significant impact on local warp and weft angles which leads to a local variation of effective material properties. Understanding the connection between the warp / weft microstructure, the resulting material properties and finally their influence on the part performance is crucial knowledge in the design process of woven composite structure.

Read more... Finite Element Simulation of Braided Composites

With braided composites, the reinforcement does not need to be cut to shape from a roll and laid down onto the mold. It is directly braided around a mandrel which has the shape of the part to be made. This speeds up the manufacturing process but requires a dedicated equipment. This process further makes it possible to produce more complex parts which, however, are limited to convex shapes and hollow profiles.

Read more... Unidirectional composites (UD) Simulation-Based Design

Unidirectional composites (UD) offer a large playground to tune optimal material properties. Thermoset and thermoplastic matrices are reinforced with different types of fibers: glass, carbon, aramid, etc. UD fibers are straight and non-crimped. In the laminate, they are laid up in specific stacking sequences, varying the fiber volume fraction, the thickness and orientation of plies.

Read more... Discontinuous Fiber Composites: Finite Element Simulation

Discontinuous fiber composites (DFC) are produced by compression molding of prepreg chips which are made of a combination of unidirectional fiber and a Thermoset or ThermoPlastic matrix. In some cases, matrix is made of thermoset which consolidate through a chemical/cure reaction at elevated temperature. However, when the curing cycle is not well monitored it can be observed some cracks that appear between the chips due to apparition of thermal stresses normal to two chips.

Read more... Hard Metal: Finite Element Simulation for Mechanical Properties on the Microstructural Level

Hard metals are functional materials with tuned performances arising from the composite microstructure. Understanding those composites on the microstructural level is key for material suppliers who need to innovate their products. Hard metals are two-phase materials with significantly differing mechanical properties on the microstructural level. Material properties are tuned by varying the content and microstructure of a hard inclusion phase. Key to further material development is to understand and optimize microstructural stresses in the composite.

Read more... FEA Based Simulation of Rubber Matrix Composite: Tires, anti-vibration systems, seals or hoses

Tires, anti-vibration systems, seals or hoses are rubber based components which turn into high-tech systems as soon as their material properties are tuned by embedded inclusions. A simple tire unfolds its performance due to influences from various scales. On the microscopic scale carbon black or mica particles are filled into the rubber matrix to compound materials with specific properties. On the belt edge a sophisticated weave of embedded steel fibers controls the footprint of the tire.

Read more... Plastic materials: Thermoplastics (PA, PP, PC, POM, PPA) and Thermosets (Epoxy, Polyurethane) reinforced with short, long or continuous glass and/or carbon fibers

For Plastic Materials such as Thermoplastics (PA, PP, PC, POM, PPA) and Thermosets (Epoxy, Polyurethane) reinforced with short, long or continuous glass and/or carbon fibers, taking into account the effect of the manufacturing process, like compression and injection molding of the performance of the part, is the most important challenge in design procedure. Enteknograte engineering team use FEA based simulation and design within advanced CAE software for investigation of modal, creep, stiffness, crash, durability/fatigue of plastic material based structures.

Read more... Composites Fatigue Finite Element Simulation

The structural durability of a component is one of the most expensive attributes to test, thus one of the most appealing for CAE. Fatigue modeling of chopped and continuous fiber polymer composites is challenging due to their anisotropic, heterogeneous and viscous material properties as well as their process-dependent microstructure. For simulation of high cycle fatigue (HCF) of fiber reinforced composites we use FEA tools Like VirtualLab Durability, nCode DesignLife , MSC CAEFatigue and FE-SAFE.

Read more... Finite Element Simulation of Crash Test and Crashworthiness with LS-Dyna, Abaqus and PAM-CRASH

Crashworthiness focuses on occupant protection to reduce the number of fatal and serious injuries. This research is responsible for developing and upgrading test procedures for evaluating motor vehicle safety. Crashworthiness research encompasses new and improved vehicle design, safety countermeasures and equipment to enhance occupant safety.

Finite Element Analysis (FEA) has been the trend in virtual crash design over the last decade. The predictive capabilities of FEA allow engineers to fully understand a crash event in a virtual environment, thus limiting the number of physical tests that need to be executed and thus saving costs.

Read more... Seat Design: Finite Element and CFD Simulation for Static & Dynamic Comfort, Whiplash, Acoustic & Thermal Comfort, Crash Test

Simulation Based Design can help us to ensure the right occupant posture, which is essential for safety, Static and Dynamic Comfort, for example by predicting the H-Point and incorporating whiplash, thermal and Acoustic comfort simulation. The ability to predict the comfort of innovative seat designs using simulation tools, a library of human models with our team experience in CFD (Siemens Start-ccm+, Ansys Fluent and OpenFoam) and FEA (Ansys LS-DYNA, Simulia Abaqus, ESI Pam-Crash and Altair RADIOSS) simulation software with integrated Artificial Intelligence and Machine Learning for innovative design, can help manufacturers to create seats that provide a superior driving experience for their customers.

Read more... Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Noise and vibration analysis is becoming increasingly important in virtually every industry. The need to reduce noise and vibration can arise because of government legislation, new lightweight constructions, use of lower cost materials, fatigue failure or increased competitive pressure. With deep knowledge in FEA, CFD and Acoustic simulation, advanced Acoustic solvers and numerical methods used by Enteknograte engineers to solve acoustics, vibro-acoustics, and aero-acoustics problems in automotive manufacturers and suppliers, aerospace companies, shipbuilding industries and consumer product manufacturers.

Read more... FEA Based Composite Material Design and Optimization: MSC Marc, Abaqus, Ansys, Digimat and LS-DYNA

Finite Element Method and in general view, Simulation Driven Design is an efficient tool for development and simulation of Composite material models of Polymer Matrix Composites, Metal Matrix Composites, Ceramic Matrix Composites, Nanocomposite, Rubber and Elastomer Composites, woven Composite, honeycomb cores, reinforced concrete, soil, bones ,Discontinuous Fiber, UD Composit and various other heterogeneous materials.

Read more... Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

We analyze system-level thermal management of vehicle component, including underhood, underbody and brake systems, and design for heat shields, electronics cooling, HVAC, hybrid systems and human thermal comfort. Our Finite Element (LS-Dyna, Ansys, Abaqus) and CFD simulation (Siemens Start-ccm+, Ansys Fluent , Ansys CFX and OpenFoam) for heat transfer analysis, thermal management, and virtual test process can save time and money in the design and development process, while also improving the thermal comfort and overall quality of the final product.

Read more... Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Machine learning is a method of data analysis that automates analytical model building. It is a branch of Artificial Intelligence based on the idea that systems can learn from data, identify patterns and make decisions with minimal human intervention. With Artificial Intelligence (AI) applications in CAE, that is Mechanical Engineering and FEA and CFD Simulations as design tools, our CAE engineers evaluate the possible changes (and limits) coming from Machine learning, whether Deep Learning (DL), or Support vector machine (SVM) or even Genetic algorithms to specify definitive influence in some optimization problems and the solution of complex systems.

Read more... Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Structural vibration can be a source for many product related problems; it can cause fatigue and durability problems as well as adverse reactions to the user or bystanders in the form of undesirable vibrations that can be felt or heard. As well, undesired structural vibrations can prevent products from operating as required and potentially becoming a safety concern. The Vibration Fatigue simulation predict fatigue in the frequency domain and it is more realistic and efficient than time-domain analysis for many applications with random loading such as wind and wave loads.

Read more... eVTOL (Electric Vertical Take-Off and Landing) & UAM (Urban Air Mobility)

FEA & CFD Based Simulation for Airworthiness Certification, Aerodynamics, Aeroacoustics and Crashworthiness

The VTOL, eVTOL and UAM market is constantly changing and evolving, so maintaining a competitive edge both within the industry and supporting mission effectiveness requires significant research and development activities. Enteknograte offers the industry’s most complete simulation solution for Urban Air Mobility (UAM) and Vertical Take off and Landing (VTOL) aircrafts.

Read more... Finite Element Analysis of Durability and Fatigue Life

Vibration Fatigue, Creep, Welded Structures Fatigue, Elastomer and Composite Fatigue with Ansys Ncode, Simulia FE-Safe, MSC CAEFatigue, FEMFAT

Durability often dominates development agendas, and empirical evaluation is by its nature time-consuming and costly. Simulation provides a strategic approach to managing risk and cost by enabling design concepts or design changes to be studied before investment in physical evaluation. The industry-leading fatigue Simulation technology such as Simulia FE-SAFE, Ansys Ncode Design Life and FEMFAT used to calculate fatigue life of multiaxial, welds, short-fibre composite, vibration, crack growth, thermo-mechanical fatigue.

Read more... Additive Manufacturing and 3D Printing

FEA Based Design and Optimization with Simufact, Abaqus, ANSYS and MSC Apex for powder bed fusion (PBF), directed energy deposition (DED) and binder jetting processes

With additive manufacturing, the design is not constrained by traditional manufacturing requirements and specific number of design parameters. Nonparametric optimization with new technologies such as Artificial Intelligence in coupled with Finite Element method, can be used to produce functional designs with the least amount of material. Additive manufacturing simulations are key in assessing a finished part’s quality. Here at Eneteknograte, dependent of the problem detail, we use advanced tools such as MSC Apex Generative Design, Simufact Additive, Digimat, Abaqus and Ansys.

Read more... Previous

Next