Simufact Welding

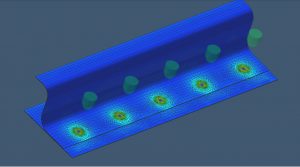

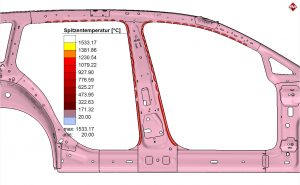

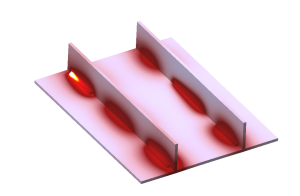

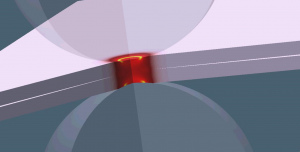

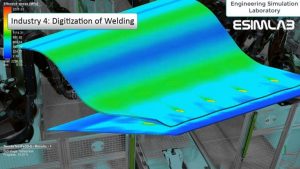

Simufact Welding is used for modelling and optimising a wide range of fusion and pressure welding processes, taking into account weld sequence and clamping. Processes such as arc welding, laser beam welding, electron beam welding, brazing, resistance spot welding as well as the generative manufacturing process ‘Direct Energy Deposition’ (DED or WAAM) can be modelled in Simufact Welding. Additionally, Simufact Welding can be used to model the heat treatment, different variants for cooling and unclamping as well as the mechanical load on welded structures.

How can Simufact Welding support you with the design of a welding process or an assembly?

Depending on the level of detail and data quality you are able to …

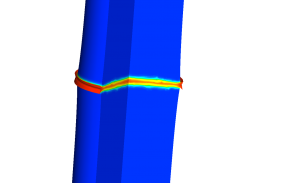

- Calculate local and global properties of a welded structure, i.e. global and local deformations, residual stresses and metallurgical phases

- Learn how changes in the assembly design (i.e. addition, movement or removal of stiffeners, changed fillet geometry) influences the final quality of the product

- Check the influence of clamping conditions, also learn if all clamps are necessary

- Investigate hot spots with respect to temperature or stresses that might lead to cracks or damage of the structure

Modular structure

Simufact Welding is a modular software, subdivided into application modules providing welding process-specific functionality and additional modules providing material data and parallelization technology boosting simulation performance.

Core functionality is provided by the Welding Hub and its associated Thermal Joining application modules, offering the possibility of pre- and postprocessing as well as calculation of thermal joining processes. Additionally, a Resistance Spot Welding module is available. An optional bundle with MSC Apex Modeler provides CAD and meshing capabilities.

Standard modules include the capability of:

- Flexible definition of equivalent heat sources for thermal joining

- Definition, visualization and editing of material data

- Possibility of parallelization

- Scaled simulation approaches

- Definition of time-temperature curves for heat treatment

Process chains and data exchange

The capability of transferring simulation results from one manufacturing step to subsequent steps is a prerequisite for result accuracy in the entire simulation process chain.

In combination with Simufact Forming it is possible to model entire process chains, for instance forming processes on components that are welded in the next step and vice versa.

Data exchange between Simufact Forming and Simufact Welding allows for stepwise calculations that are based on previous results. This approach makes it possible to calculate welded assemblies, or to carry out process chain simulations.

Therefore it is possible to integrate welding with pre- and post-processing in a common numerical framework. The easy data transfer allows consideration of the material history with respect to a previous forming process, as well as the fatigue response of a calculated weldment.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae(Simufact, Digimat, Nastran, MSC APEX, Actran Acoustic solver), ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

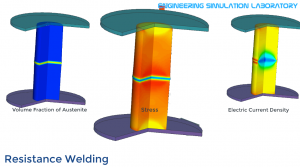

Resistance Spot Welding: Finite Element Simulation of RSW

Finite Element Simulation of Arc Welding

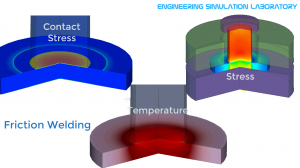

Pressure Welding FEA Simulation: Friction welding, Resistance welding, Friction spot welding

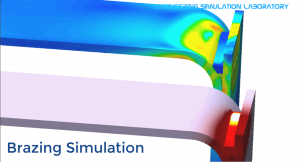

Finite Element Simulation of Brazing

Fatigue Analysis of Welded Structures

Finite Element Simulation of Laser Beam / Electron Beam Welding

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Metal Forming Simulation

Finite Element Simulation of Heat Treatment

Additive Manufacturing and 3D Printing

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Finite Element Simulation of Crash Test and Crashworthiness with LS-Dyna, Abaqus and PAM-CRASH

Acoustics and Vibration Simulation