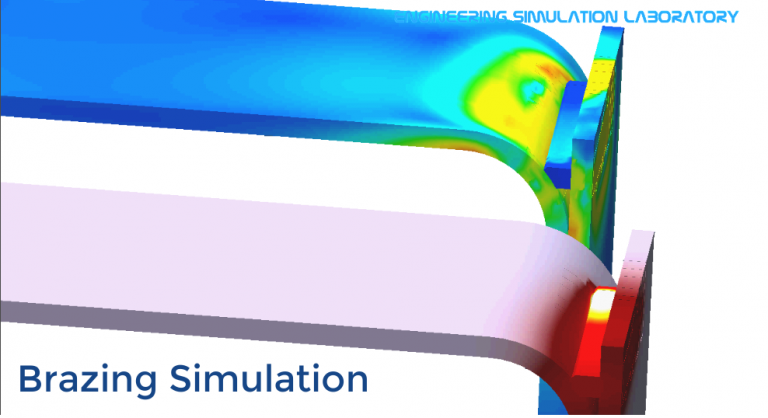

Finite Element Simulation of Brazing

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

Brazing is a thermal joining process which connects metal components with melted filler material. The filler usually has lower melting point compared to components. Main advantages of brazing lies in relatively low heat input and the capability to create a joint of considerable strength and durability.

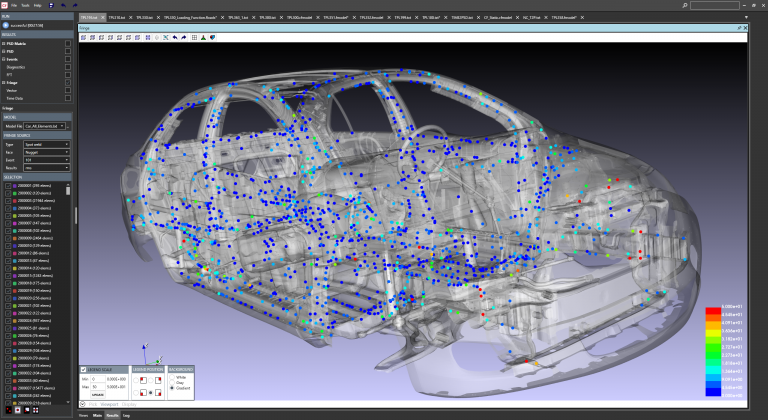

Enteknograte engineers simulate the Welding with innovative CAE and virtual prototyping available in the non-linear structural codes LS-DYNA, Ansys, Comsol, Simufact Welding and ABAQUS. We are experienced with FEA Welding simulation.

Enteknograte Engineers can simulate any type of welding such as Arc Welding, laser Beam Welding, RSW, FSW and transfer the results of welding simulation for next simulation like NVH, Crash test, Tension, Compression, shear test and fatigue simulation.

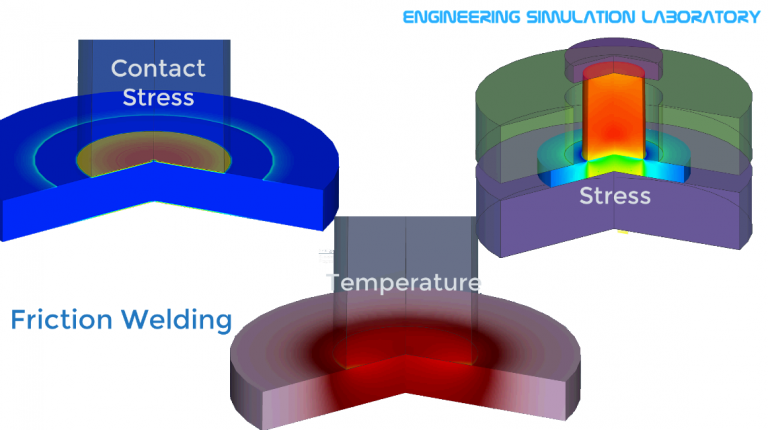

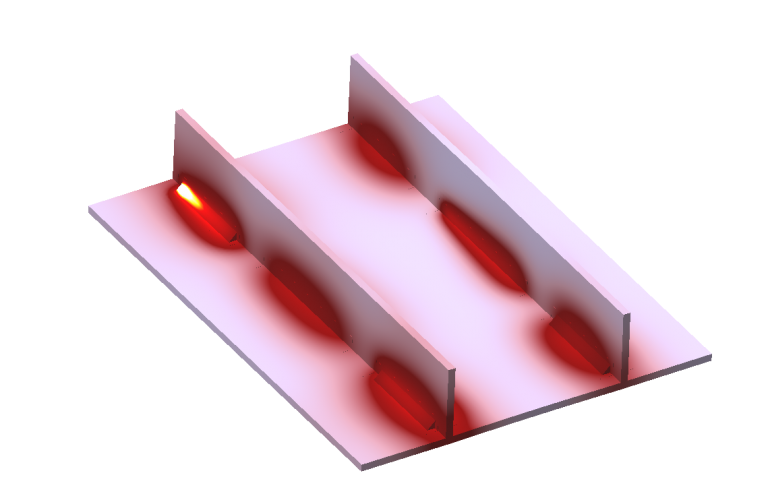

Welding cause to The components, commonly made of steel(s), are temporarily heated to specific temperatures Distribution. Taking into account the rate of heating and cooling, the material properties of a component can be altered and improved. The presence of certain agents can lead to changes in the carbon or nitrogen content of the component. In all welding processes, there are several decisive and important factors: Time (heating and holding time), temperature, atmosphere, and quenching or cooling conditions. In principle, there are two kinds of welding effect as heat treatment processes on material points:

processes resulting in a thorough change of the microstructure such as annealing and hardening

processes that result in merely changing regions close to the surface of the component such as diffusion and coating processes, carburization, case hardening, nitrating, boriding

Enteknograte Engineers simulate any type of welding with any level of complexity:

• Arc Welding

• Electron Beam Welding

• Laser Beam Welding

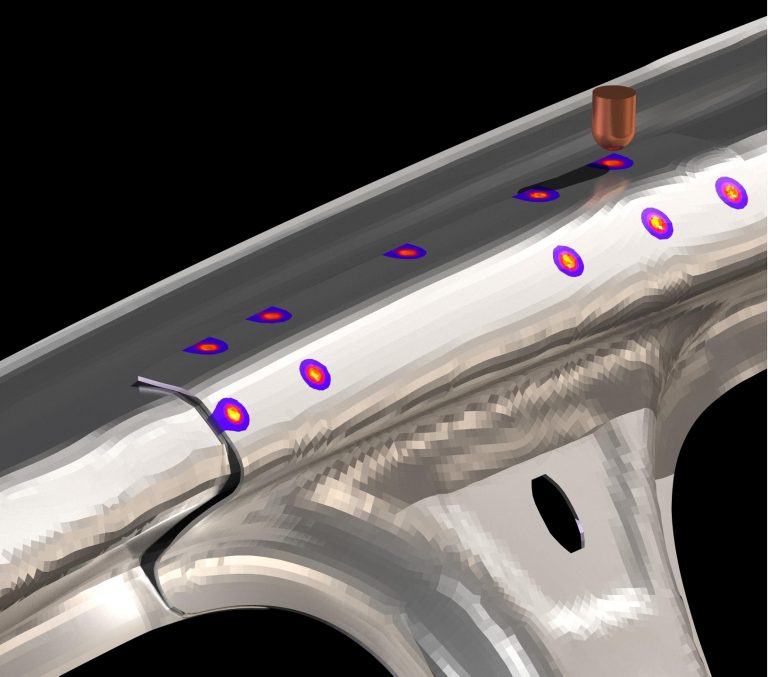

• RSW (Resistance Spot Welding)

• FSW (Friction Stir Welding)

• Pressure Welding

• Stress Relief Heat Treatment

• Fatigue Life of Welded Structures

• NVH, Crash test, Tension, Compression and shear test behavior of Welded Structures

Why we use Simufact as default for welding simulation

Simufact Welding predicts distortions and residual stresses by virtually try-outs and helps the user to determine appropriate strategies to minimize them. It is the only simulation software which automatically considers the complex contact situation between the components, which in turn allows conclusions about the properties of the weld seam, in particular its strength, to be drawn. Simufact Welding achieves this by calculating the microstructural properties within the heat-affected zone, which also gives the user a valuable insight into identifying welding defects, such as hot cracks in the simulation, and how to avoid them in practice.

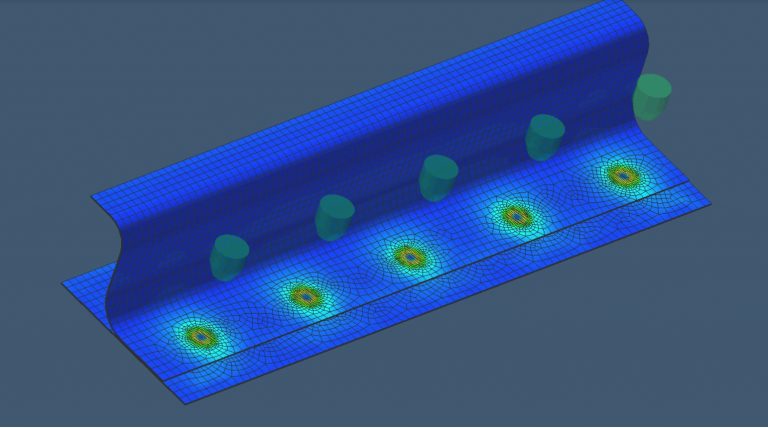

Resistance Spot Welding: Finite Element Simulation of RSW

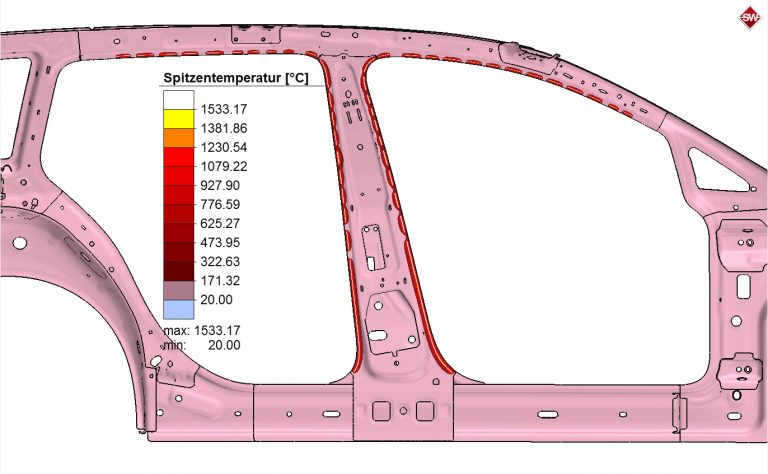

Finite Element Simulation of Arc Welding

Pressure Welding FEA Simulation: Friction welding, Resistance welding, Friction spot welding

Finite Element Simulation of Brazing

Fatigue Analysis of Welded Structures

Finite Element Simulation of Laser Beam / Electron Beam Welding

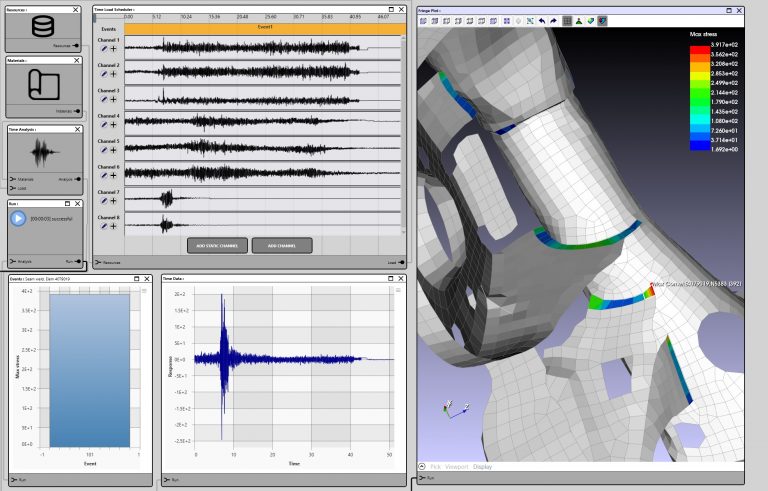

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Metal Forming Simulation

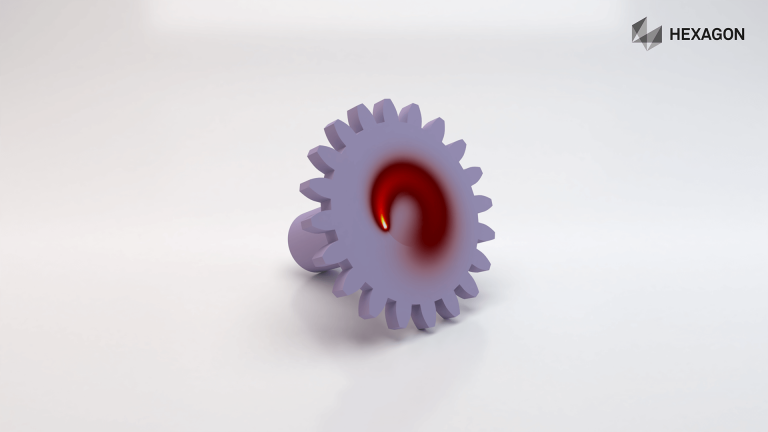

Finite Element Simulation of Heat Treatment

Additive Manufacturing and 3D Printing

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Finite Element Simulation of Crash Test and Crashworthiness with LS-Dyna, Abaqus and PAM-CRASH

Acoustics and Vibration Simulation