Resistance Spot Welding: Finite Element Simulation of RSW

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

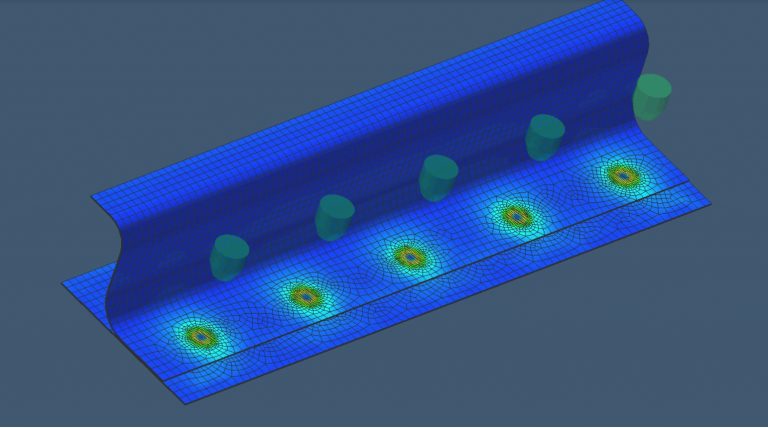

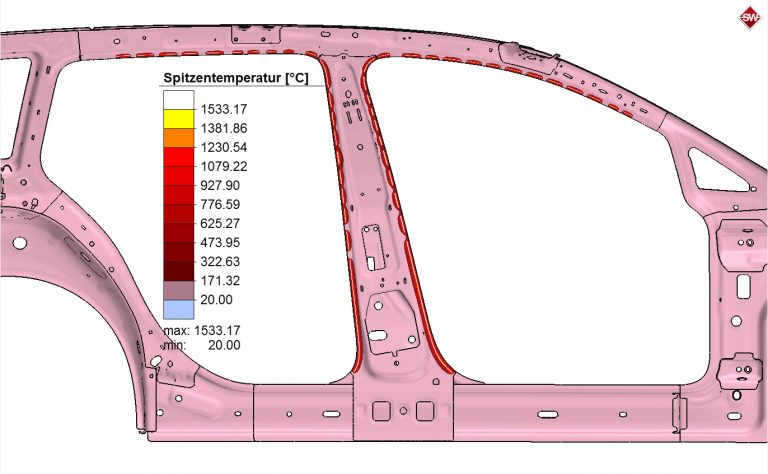

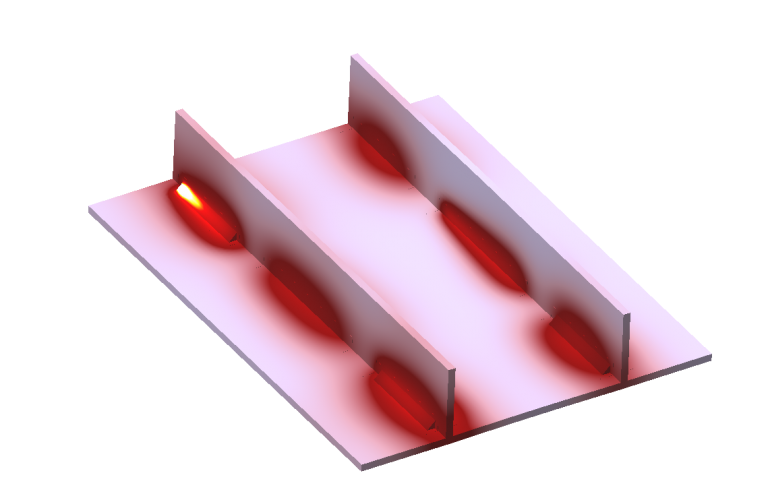

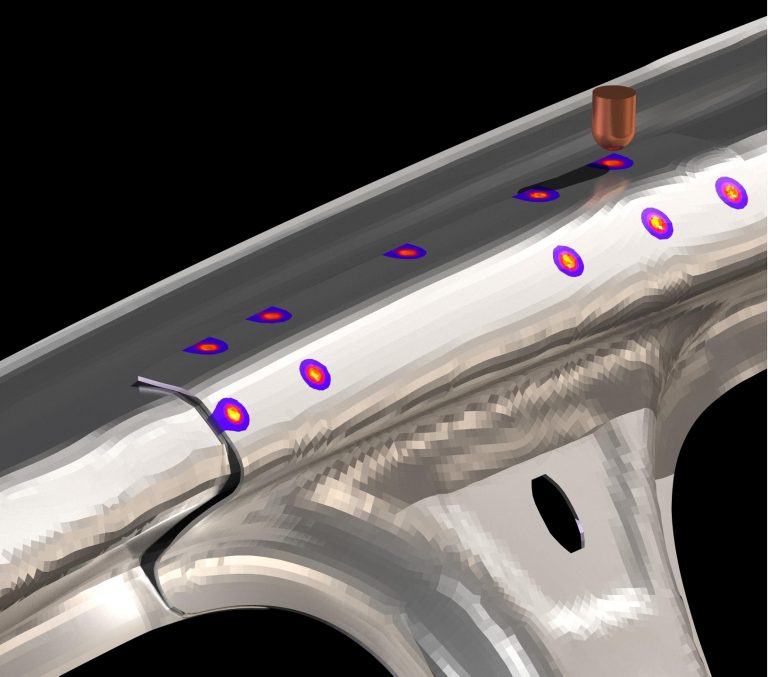

Resistance Spot Welding is a pressure welding process during which the sheets are pressed together locally with the help of fitted copper electrode welding guns. The electrical current between the weld guns causes a heating and melting of the joining partners, creating a small circular welded area between them.The standard approach in a RSW model contains fully coupled electrical, thermal, metallurgical and mechanical steps, so the heat generation is calculated due to Joule’s heating coming from electrical current and resistivity between components.

Research & developments in resistance spot welding:

- The optimization of welding processes

- Usage of new high-performance robotic welding guns

- New self-regulating process control, which can also cover an increased range of material thickness combinations

- The use of control devices for quality assurance and a reduction in the resources needed to inspect parts and processes.

- Investigations of hybrid welding processes, such as spot-weld bonding

- Achieving consistent quality by using spot welding systems on a circulating process belt

- Investigations of spot welding of CF components by the use of local metal structures

One way to preserve the welding expertise within a company and to reduce trial costs is to use a welding simulation software that offers both structure and process simulations. This allows the potential process parameters to be virtually and investigated with appropriate parameters being documented.

Enteknograte engineers simulate the Welding with innovative CAE and virtual prototyping available in the non-linear structural codes LS-DYNA, Ansys, Comsol, Simufact Welding and ABAQUS. We are experienced with FEA Welding simulation.

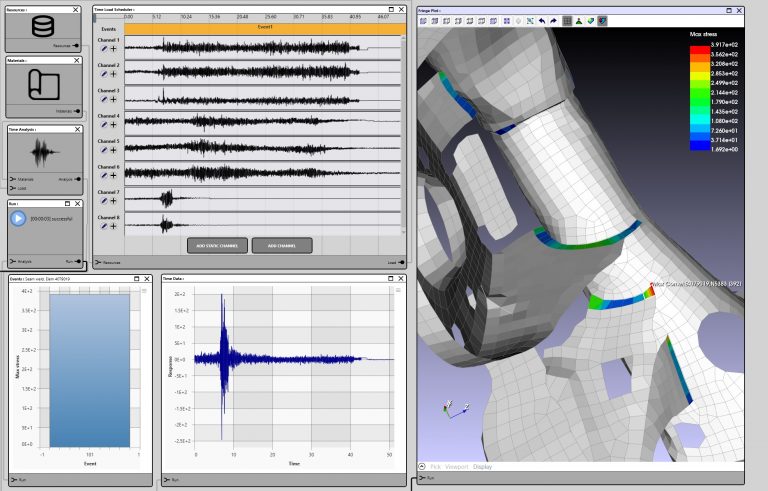

Enteknograte Engineers can simulate any type of welding such as Arc Welding, laser Beam Welding, RSW, FSW and transfer the results of welding simulation for next simulation like NVH, Crash test, Tension, Compression, shear test and fatigue simulation.

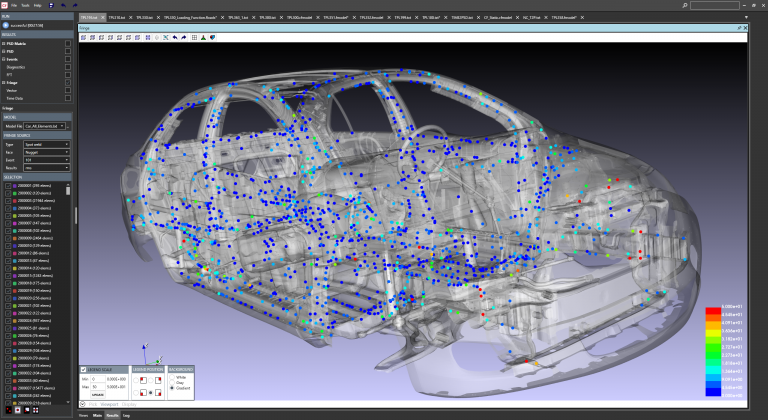

Simufact Welding for RSW: Industrial Welding Process Design

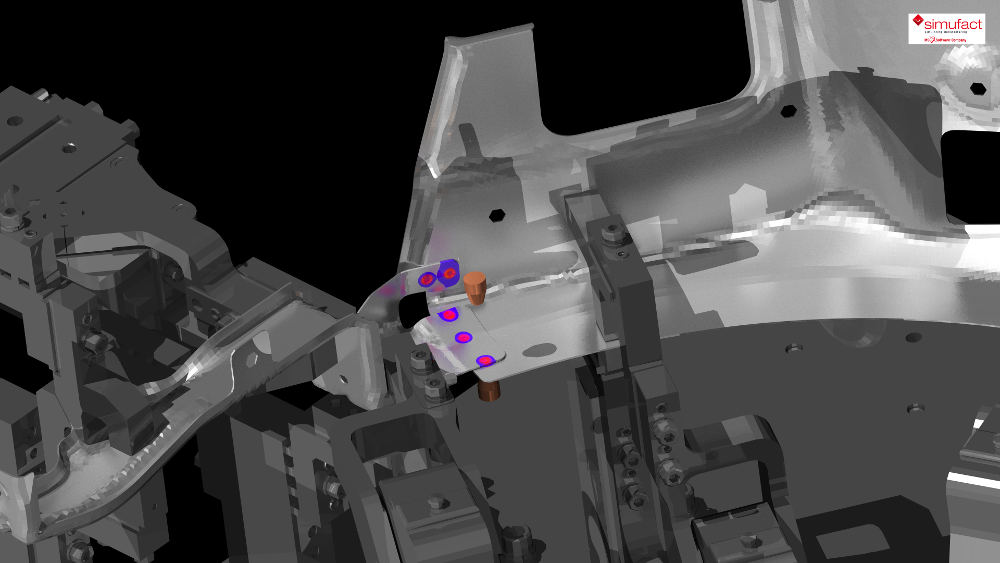

For a defined welding process, including planned welding sequence as well as clamping and unclamping, Simufact Welding provides the possibility to calculate expected distortions, stresses and material properties after welding. Furthermore, the software allows for estimating the effects of tack welds on expected gap formation during and after welding. Especially calculation of stresses and material properties is a big advantage of the simulation because those are result values that are difficult to measure on real components.

The process itself (i.e. the welding sequence) can easily be changed in the model, providing a quick possibility to investigate its influence on distortions and properties of the welded assembly. Furthermore, it is possible to change the position, applied forces and unclamping times in order to calculate the influence of clamping tools on final results.

Enteknograte engineers simulate the Welding with innovative CAE and virtual prototyping available in the non-linear structural codes such as LS-DYNA, Ansys, Comsol, Simufact Welding, ESI SysWeld and ABAQUS. The Finite element analysis of welding include Arc Welding, laser Beam Welding, RSW, FSW and transfer the results of welding simulation for next simulation like NVH, Crash test, Tension, Compression and shear test and fatigue simulation. We can develop special purpose user subroutine (UMAT) based on clients need to empower simulation environment to overcome any complicated problem in heat load condition, phase change and user defined material constitutive equation.

Enteknograte Engineers simulate any type of welding with any level of complexity:

• Arc Welding

• Electron Beam Welding

• Laser Beam Welding

• RSW (Resistance Spot Welding)

• FSW (Friction Stir Welding)

• Pressure Welding

• Stress Relief Heat Treatment

• Fatigue Life of Welded Structures

• NVH, Crash test, Tension, Compression and shear test behavior of Welded Structures

Why we use Simufact as default for welding simulation

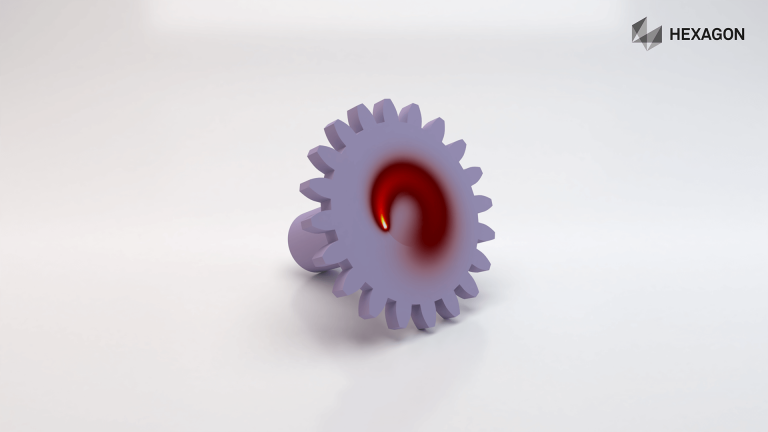

Simufact Welding predicts distortions and residual stresses by virtually try-outs and helps the user to determine appropriate strategies to minimize them. It is the only simulation software which automatically considers the complex contact situation between the components, which in turn allows conclusions about the properties of the weld seam, in particular its strength, to be drawn. Simufact Welding achieves this by calculating the microstructural properties within the heat-affected zone, which also gives the user a valuable insight into identifying welding defects, such as hot cracks in the simulation, and how to avoid them in practice.

Resistance Spot Welding: Finite Element Simulation of RSW

Finite Element Simulation of Arc Welding

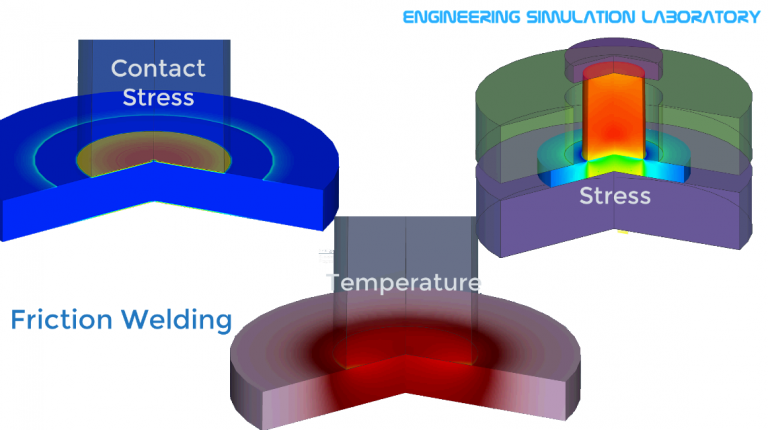

Pressure Welding FEA Simulation: Friction welding, Resistance welding, Friction spot welding

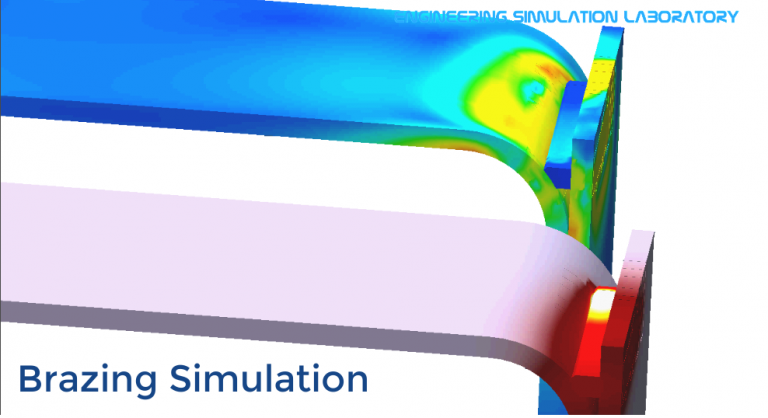

Finite Element Simulation of Brazing

Fatigue Analysis of Welded Structures

Finite Element Simulation of Laser Beam / Electron Beam Welding

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Metal Forming Simulation

Finite Element Simulation of Heat Treatment

Additive Manufacturing and 3D Printing

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Finite Element Simulation of Crash Test and Crashworthiness with LS-Dyna, Abaqus and PAM-CRASH

Acoustics and Vibration Simulation