FEA (Finite Element) Welding Simulation: RSW (Resistance Spot Welding), FSW (Friction Stir Welding), Pressure Welding, Arc, Electron and Laser Beam Welding

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

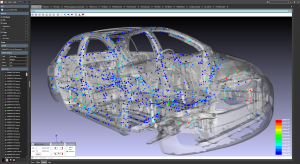

Enteknograte engineers simulate the Welding with innovative CAE and virtual prototyping available in the non-linear structural codes such as LS-DYNA, Ansys, Comsol, Simufact Welding, ESI SysWeld and ABAQUS. The Finite element analysis of welding include Arc Welding, laser Beam Welding, RSW, FSW and transfer the results of welding simulation for next simulation like NVH, Crash test, Tension, Compression and shear test and fatigue simulation. We can develop special purpose user subroutine (UMAT) based on clients need to empower simulation environment to overcome any complicated problem in heat load condition, phase change and user defined material constitutive equation.

Enteknograte Engineers simulate any type of welding with any level of complexity:

• Arc Welding

• Electron Beam Welding

• Laser Beam Welding

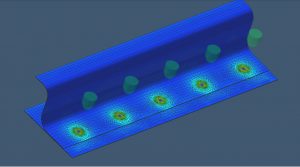

• RSW (Resistance Spot Welding)

• FSW (Friction Stir Welding)

• Pressure Welding

• Stress Relief Heat Treatment

• Fatigue Life of Welded Structures

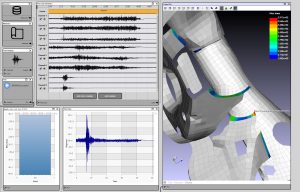

• NVH, Crash test, Tension, Compression and shear test behavior of Welded Structures

Why we use Simufact as default for welding simulation

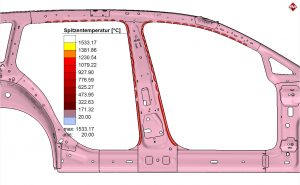

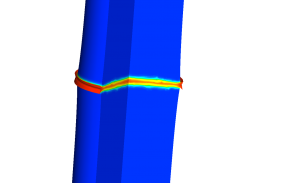

Simufact Welding predicts distortions and residual stresses by virtually try-outs and helps the user to determine appropriate strategies to minimize them. It is the only simulation software which automatically considers the complex contact situation between the components, which in turn allows conclusions about the properties of the weld seam, in particular its strength, to be drawn. Simufact Welding achieves this by calculating the microstructural properties within the heat-affected zone, which also gives the user a valuable insight into identifying welding defects, such as hot cracks in the simulation, and how to avoid them in practice.

Simufact Welding assists in finding the optimal clamping devices based on the implementation of real tool geometries, while considering clamping forces and stiffness. Besides the clamping concepts, also the suitable welding sequences can be identified with Simufact Welding. The software predicts the final contour of the assembly and helps to achieve serial production with minimum tolerances. A new visualization concept ensures that the entire welding process, with all its process steps, can be reviewed immediately, influencing factors can be visualized and different variants are comparable at a single glance.

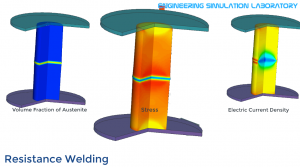

Resistance Spot Welding: Finite Element Simulation of RSW

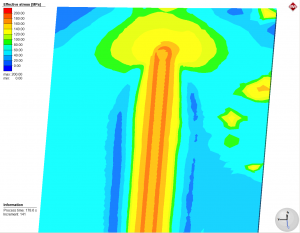

Finite Element Simulation of Arc Welding

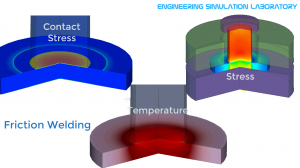

Pressure Welding FEA Simulation: Friction welding, Resistance welding, Friction spot welding

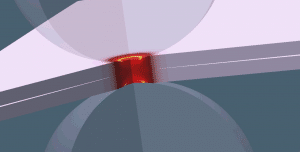

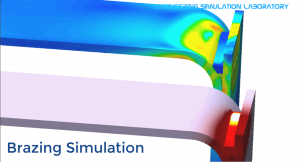

Finite Element Simulation of Brazing

Fatigue Analysis of Welded Structures

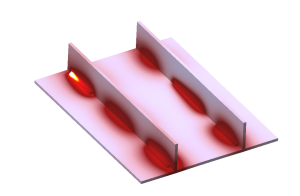

Finite Element Simulation of Laser Beam / Electron Beam Welding

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Metal Forming Simulation

Finite Element Simulation of Heat Treatment

Additive Manufacturing and 3D Printing

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Finite Element Simulation of Crash Test and Crashworthiness with LS-Dyna, Abaqus and PAM-CRASH

Acoustics and Vibration Simulation