Fire, Smoke Movement and Explosions

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

Fire and smoke propagation represents a significant risk for public safety in buildings, tunnels and underground rail systems. Smoke management systems are critical life-saving devices, and their expected performance must be evaluated in the design stage. Fire suppression systems must also be understood and optimized.

Enteknograte offers a Virtual Engineering approach with CFD and FEA tools such as MSC Cradle, Ansys Fluent, Siemens Star-CCM+ for flows simulation and FEA based Codes such as ABAQUS, Ansys, Nastran and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Material resistance to explosion, fire and extreme heat, as well as structural deterioration from catastrophic events, must be analyzed accurately. Simulating explosions and fire scenarios is an important stage of a performance-based design cycle. The results can demonstrate that smoke/fire management system designs maintain both safe conditions for occupants and the structural integrity of the building.

Enteknograte engineers participate in method development, advanced simulation work, software training and support. Over experiences in engineering consulting and design development enables Enteknograte’s engineering team to display strong/enormous client focus and engineering experience.

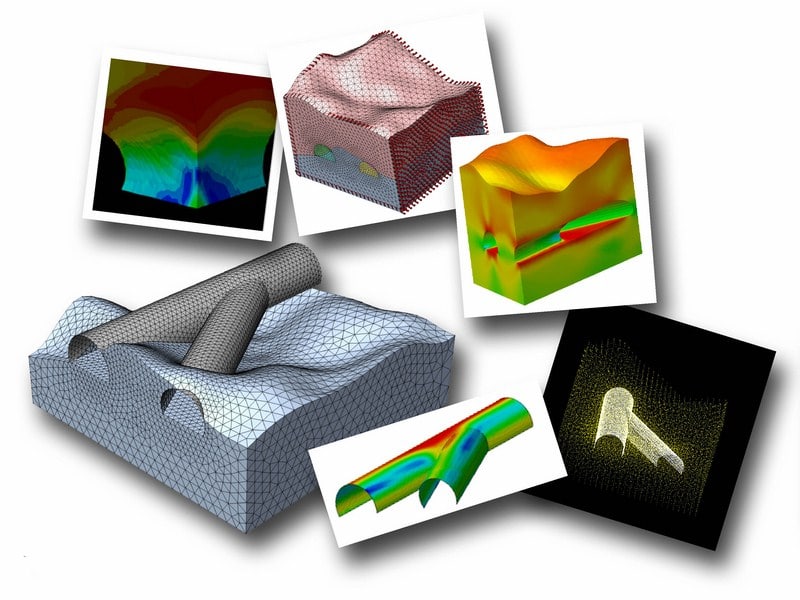

Contemporary design requirements associated with the protection of life and property often require consideration for blast effects resulting from either accidental or intentional explosions. Proper treatment of blast effects in structural systems requires specialized knowledge ranging from non-linear responses of structures to short-duration dynamic loading. Enteknograte’s Research engineers have extensive training and experience in managing all structural response considerations related to high-energy events, including blast design, explosion effects and mitigation, and finite clement modeling of blast events. Design and validation of structures against blast loads are important for modern society in order to protect and secure its citizen. Since it is a challenge to validate and optimise protective structures against blast loads using full-scale experimental tests, we have to turn our attention towards advanced numerical tools like the CFD and finite element method.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Finite element analysis for Earthquake engineering and Seismic Design: Structural, Soil and Rocks dynamics

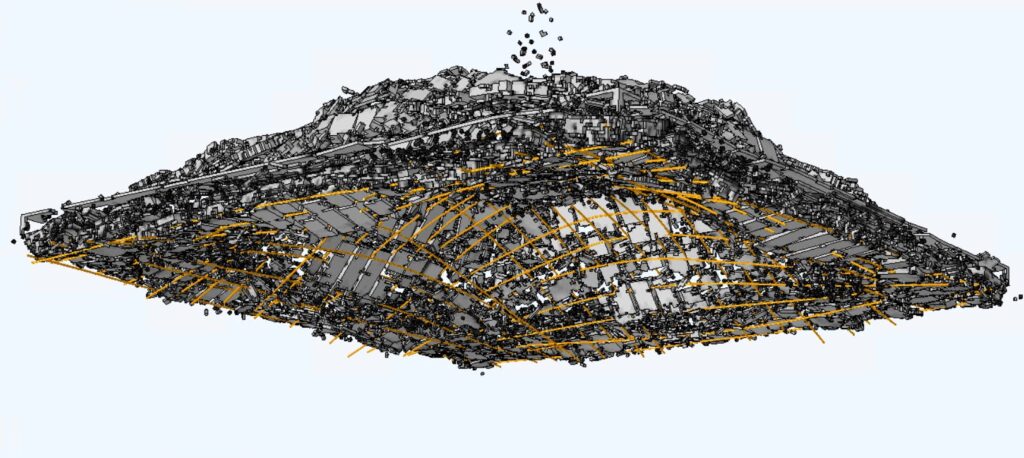

Finite element simulation of Tunnel

FEA and CFD Based Bridge Simulation

Fluid Structure Interaction (FSI)

Finite element analysis of concrete: Discrete cracking, Smeared crack and XFEM for concrete fracture and damage Simulation

Geotechnical Simulation: Finite Element for Soil and Rock Mechanics in Foundations, Embankments, Tunnels, Excavations, Slope Stability, Mines and Dams

Finite Element Simulation of Dam

Ventilation and Comfort: CFD and FEA Modeling

Architectural Acoustic Consulting Services: Environmental Noise, Auralization, Sound and Vibration Isolation per ASTM and ANSI Standards

Civil Engineering: Seismic Design, Earthquake, Tunnel, Dam, Concrete Structures and Geotechnical Multiphysics Simulation

Finite Element Analysis of Durability and Fatigue Life

FEA (Finite Element) Welding Simulation: RSW (Resistance Spot Welding), FSW (Friction Stir Welding), Pressure Welding, Arc, Electron and Laser Beam Welding

Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Blast, Explosion & Fire: Blast Resistance with Protection Against Ballistic Attacks