Ansys Additive Manufacturing: Topology Optimization, Structural & Thermal Analysis and Design Validation with FEA, AI & Machine Learning

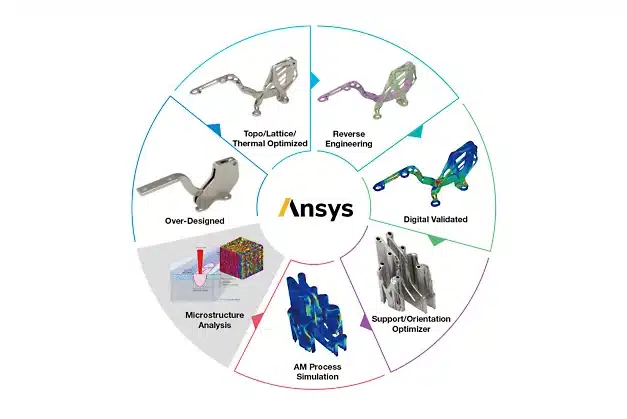

A comprehensive solution for designs, engineers and analysts, Ansys Additive Suite spans the entire workflow – from design for additive manufacturing (DfAM) through validation, print design, process simulation and exploration of materials. Topology and Lattice Optimization, Comprehensive inlet and outlet condition, Metal PBF Process Simulation, Distortion Compensation, Build Failure Prediction, Material Analysis, Melt Pool, Porosity and Microstructure Predictions, Design Validation, Structural and Thermal Analysis, Process Simulation, AI and Machine Learning.

Ansys Topology Optimization for 3D Printing

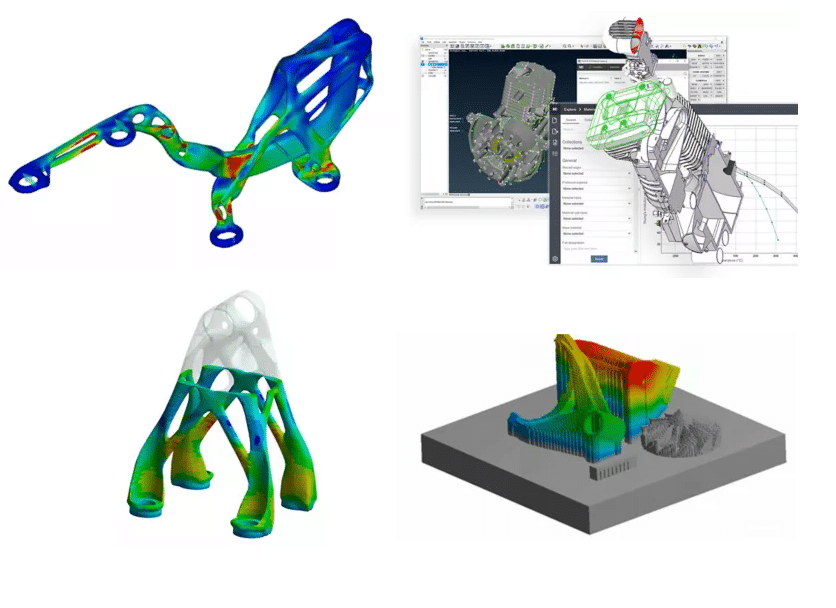

The innovation of 3D printing has changed the design landscape by making it possible to build virtually any shape without regard for design-for-manufacturability rules. Now Ansys provides designers with the tool they need to take full advantage of these capabilities — automated topology optimization integrated with Ansys’ full suite of multiphysics software. The new Ansys topology optimizer dramatically reduces the engineering cost and lead time required to design a new generation of parts or products that are optimized to reduce weight and manufacturing cost while delivering the same performance as the current generation.

Ansys Topology Optimization capabilities expands the possibilities of design process performance targets. Whether your focus is on reducing weight in an airplane, or optimizing the design of a civil structure, Ansys Topology Optimization in Discovery and Mechanical provides opportunities to design creatively with speed and efficiency.

Our capabilities account for manufacturing constraints such as 3-axis milling, overhang prevention techniques and supports multiple load cases and physics, including modal and structural simulations.

What’s most impressive is the optimization speed, allowing multiple iterations to be run in seconds and providing powerful guidance early in the design process when it matters most.

STL File and Geometry Manipulation: Utilize STL file and geometry manipulation for geometry repair, lattice creation and cleanup of parts using the software’s faceted data tools.

Structural and Thermal Analysis and Design Validation: Utilize full nonlinear and linear analysis capabilities to validate designs under a vast range of scenarios. Both thermal and structural loading conditions can be applied to understand performance and durability.

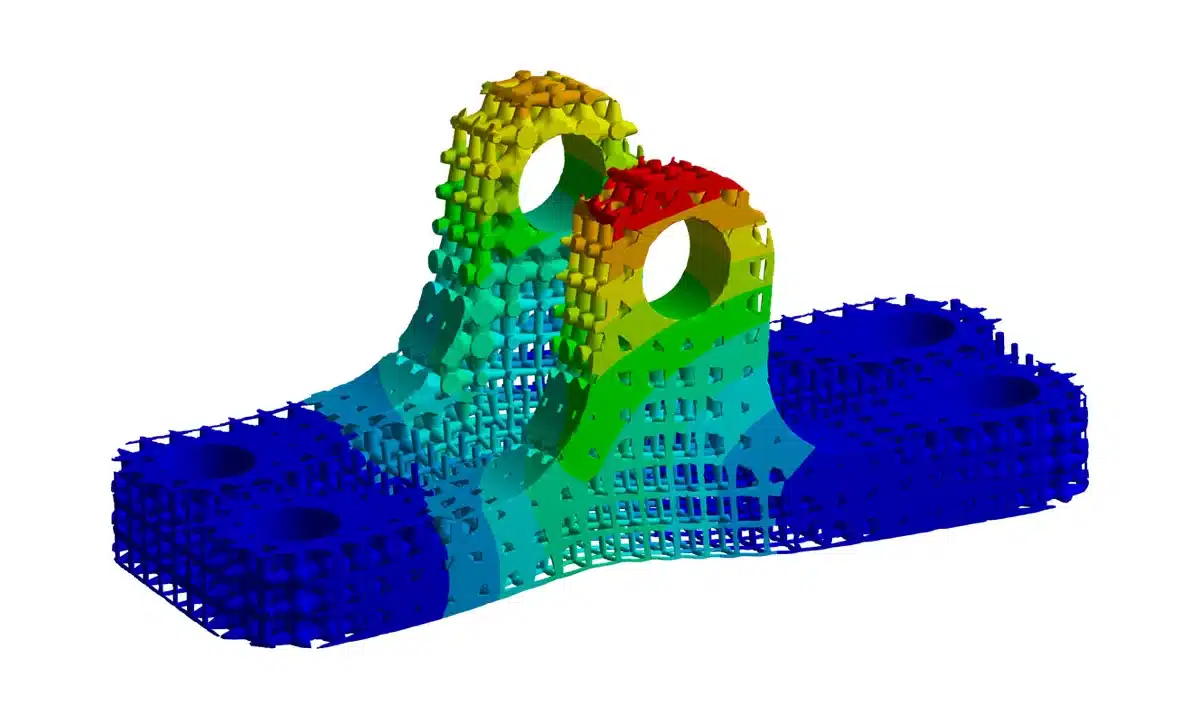

Additive Process Simulation: Predict part shape, distortion and stresses before printing with this native feature. Specifically designed for users familiar with this environment, print simulation facilitates the set up and solving of print simulations. Flexibility allows for adjusting workflow settings as needed.

A standalone application for design-stage investigation of materials and optimal machine parameters. Capabilities include:

- Material analysis tool for Additive Manufactured parts

- Porosity prediction

- Microstructure prediction

- Grain morphology

- Material tuning wizards

- Power Bed Fusion (PBF)

- Direct Energy Deposition (DED)

- Metal Sintering

- Machine Learning (ML) Thermal Strain

Using Machine Learning and AI for Additive Manufacturing

The key challenges for large-scale adoption of AM in industry are speed and reliability. How can you rapidly optimize process parameters for additively manufactured parts, thus reducing time to market? Overcoming these challenges is made even more difficult because every AM process has its own set of process parameters, including material properties, manufacturing settings, and changing environmental conditions.

Even just focusing on material properties can result in a large number of variables. The powder chemistry of an alloy can vary widely because of small levels of impurities that can change the composition of every batch. What percentage of variance in the concentration of titanium in a Ti-6Al-4V alloy powder can be tolerated before an AM build fails? How do levels of impurities such as oxygen, iron, carbon, and nitrogen affect the tensile strength of the resulting AM part?

Here is where AI helps us to overcome problems. Artificial Intelligence, Machine learning (ML) and simulation are rapidly evolving fields transforming how we design, verify, and optimize complex systems. Machine learning (ML) algorithms, often based on neural network approaches, build models from sample data, known as the training data. Based only on what they have “learned” from this data without further explicit programming, these models support tasks including:

- Predicting missing values in the rest of the dataset

- Predicting outputs for a new set of input variables

- Optimizing performance by predicting which inputs will best achieve desired outputs

- Identifying outliers, anomalies, or clusters in the data

- Identifying which inputs are strong drivers of which outputs

Machine learning uses existing AM project data to build predictive models that identify key process-property relationships, guide your testing program, and propose optimal processing parameters. When you have too little data, ML helps you focus your data acquisition efforts efficiently by identifying key parameters that are missing and when you have too much data, ML can extract the key parameters that are critical to predicting AM build success.

Additive manufacturing allows companies to print parts that are impossible or very expensive to produce with traditional subtractive manufacturing methods. But organizations that are working to develop additive manufacturing into a real-world manufacturing process often must go through multiple trial-and-error processes to successfully generate high-fidelity parts. Ansys Additive Simulation guides engineers to successfully create parts and processes at much lower cost and lead time than is required for trial and error.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae(Simufact, Digimat, Nastran, MSC APEX, Actran Acoustic solver), ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Directed Energy Deposition (DED), Direct Metal Deposition (DMD) & Laser Metal Deposition (LMD): Finite Element Simulation-Based Design

Finite Element Simulation of Powder Bed Fusion Processes

Metal Binder Jetting: Finite Element Simulation-Based Design

Additive Manufacturing of Plastics, Reinforced Polymers & Composites

Generative Design for Additive Manufacturing & Lattice Structures: Topology, Shape and Bead Optimization

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Additive Manufacturing and 3D Printing

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Finite Element Simulation of Heat Treatment

Finite Element Analysis of Durability and Fatigue Life

Finite Element Simulation of Laser Beam / Electron Beam Welding

Finite Element Welding Simulation: RSW, FSW, Arc, Electron and Laser Beam Welding

Metal Forming Simulation: FEA Based Design and Optimization

Casting: Finite Element and CFD Simulation Based Design

FEA Based Composite Material Design and Optimization: MSC Marc, Abaqus, Ansys, Digimat and LS-DYNA

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

In Silico Medical & Biomedical Device Testing: Finite Element & CFD Simulation and Design, Considering FDA & ASME V&V 40

Simulation of Plasma Based Devices: Microwave Plasma and RF Plasma Analysis with Coupling Particle in Cell (PIC), MHD, CFD and FEA Solvers

Electromagnetic Multiphysics FEA & CFD Based Simulation

Hydrodynamics: Coupled CFD and FEA simulation for FSI Analysis

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation