Generative Design for Additive Manufacturing & Lattice Structures: Topology, Shape and Bead Optimization

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

Generative Design is an innovation that significantly alters this way of thinking. It leverages topology optimization, artificial intelligence, and advanced simulation which automatically creates multiple viable design alternatives by specifying simple design criteria.

For additive manufacturing, Optimized structure is the most important thing, and there is big effort to include all aspect of real-world physics to simulation for accurately simulate the process. In the early stages of design, FEA based Simulation in combination with artificial intelligence for Optimization can reveal various design options to reduce weight and materials, while also maintaining and improving the rigidity and durability of the product. In the late stages of design, when improvements and major changes are limited, we can investigate stress points in conjunction with stress reducing materials to find solutions without making geometrical changes.

Generative Design bridges the engineering skills gap between theoretical knowledge and practical experience in mechanical systems and components. It boosts engineering creativity and innovation, drives efficiency, decreases weight, and reduces time-to-market for new products. Generative Design saves costs at every stage of the product’s lifecycle.

Topology Optimization

Enteknograte engineers uses topology optimization in conceptual design to create lighter but stiffer parts and structures. we offer the ability to make designs ready-to-manufacture meaning that fewer prototypes are built, and fewer physical tests are needed, saving time and money. Our engineers can produce strong and lightweight parts through material reduction strategies. The final topology investigated to evaluate the fatigue and durability criteria by our engineers.

Shape Optimization

With shape optimization, our engineers can not only optimize the shape of your designs during initial design, but also go back and improve old designs. These structural optimizations modify surface geometries to suggest the best shapes for structural and performance needs.

Bead Optimization

Through bead optimization our engineers can improve the static and dynamic properties of shell structures.

Lattice Structures

Additive manufacturing offers the ability to build lightweight components designed through topology optimization, incorporating lattice structures to provide conformal cooling. Lattices are repeated arrangements of unit cells. The numerous shapes and sizes available for unit cells have led to a breakthrough in the production of more robust lightweight materials and structures.

In the modern manufacturing world, lattice structures are being used for internal support, reducing the amount of material or improving the strength-to-weight ratio. Medical implants, automotive and aerospace and defense components are a few major applications which have directly benefited from lattice structures. To further improve the efficiency of these lattice structures, they can be optimized for the required in-service loading conditions.

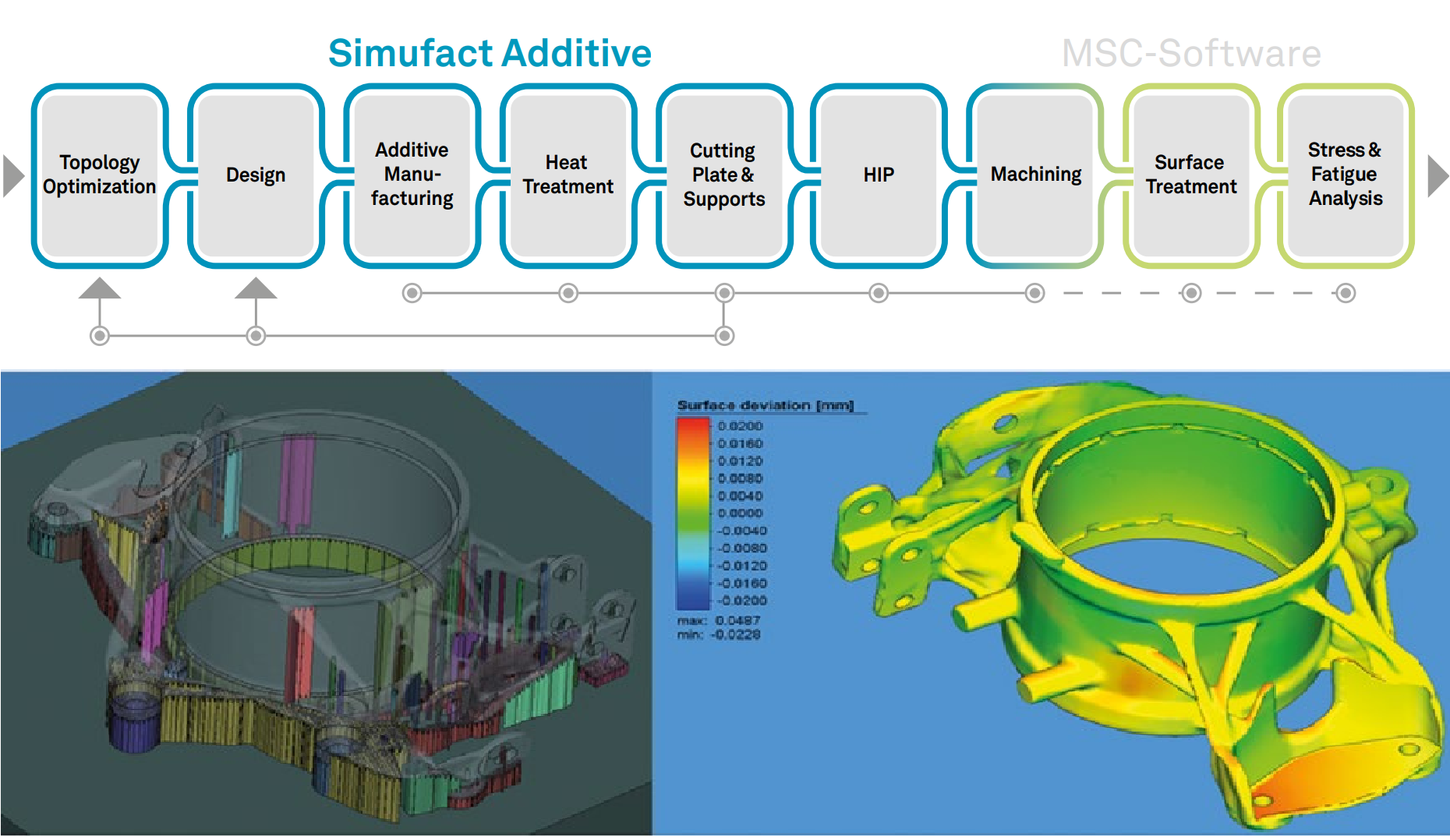

Our solution’s functionality helps you to answer challenges in Metal AM (Additive Manufacturing) Finite Element Simulation-based design and Optimization:

- Identify the best build orientation

- Determine and compensate final part distortionGenerate and optimize support structures

- Process window pre-scanning tool

- Powder coating

- Melt pool shape and dimensions

- Consolidated material porosity

- Surface roughness

- Thermal history as a function of deposition strategy

- Residual stresses

- Distortion during build process and after release

- Identify manufacturing issues such as cracks, layer offsets, recoater contact

- Predict the influence of several components in the build space

- Identify cold and hot spots due to thermal/thermo-mechanical simulation

- Examine conditions of highly elevated temperatures and pressures – HIP proces

Optimizing the design parameters for additive manufacturing

FEA Based Simulation enable our engineering team to gain insight into the microscale meltpool phenomena by performing full factorial studies with various process parameters for determine the best process parameters for any machine/material combination, and ensures the achievement of the highest integrity parts, as well as the expected microstructure and physical properties:

- Optimize and fine-tune their machine and material parameters.

- Develop new metal powders and metal AM (Additive Manufacturing ) materials and material specifications.

- Determine optimum machine/material parameters.

- Control microstructure and material properties.

- Manufacture using new metal powders faster and more efficiently.

- Reduce the number of experiments needed to qualify components.

- Mitigate risk while accelerating innovation.

- Analyze Porosity and Meltpools.

- Thermal history and microstructure information.

- Determines the percentage of porosity in a part due to lack of fusion.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae(Simufact, Digimat, Nastran, MSC APEX, Actran Acoustic solver), ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Directed Energy Deposition (DED), Direct Metal Deposition (DMD) & Laser Metal Deposition (LMD): Finite Element Simulation-Based Design

Finite Element Simulation of Powder Bed Fusion Processes

Metal Binder Jetting: Finite Element Simulation-Based Design

Additive Manufacturing of Plastics, Reinforced Polymers & Composites

Generative Design for Additive Manufacturing & Lattice Structures: Topology, Shape and Bead Optimization

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Additive Manufacturing and 3D Printing

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Finite Element Simulation of Heat Treatment

Finite Element Analysis of Durability and Fatigue Life

Finite Element Simulation of Laser Beam / Electron Beam Welding

Finite Element Welding Simulation: RSW, FSW, Arc, Electron and Laser Beam Welding

Metal Forming Simulation: FEA Based Design and Optimization

Casting: Finite Element and CFD Simulation Based Design

FEA Based Composite Material Design and Optimization: MSC Marc, Abaqus, Ansys, Digimat and LS-DYNA

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

In Silico Medical & Biomedical Device Testing: Finite Element & CFD Simulation and Design, Considering FDA & ASME V&V 40

Simulation of Plasma Based Devices: Microwave Plasma and RF Plasma Analysis with Coupling Particle in Cell (PIC), MHD, CFD and FEA Solvers

Electromagnetic Multiphysics FEA & CFD Based Simulation