Directed Energy Deposition (DED), Direct Metal Deposition (DMD) & Laser Metal Deposition (LMD): Finite Element Simulation-Based Design

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

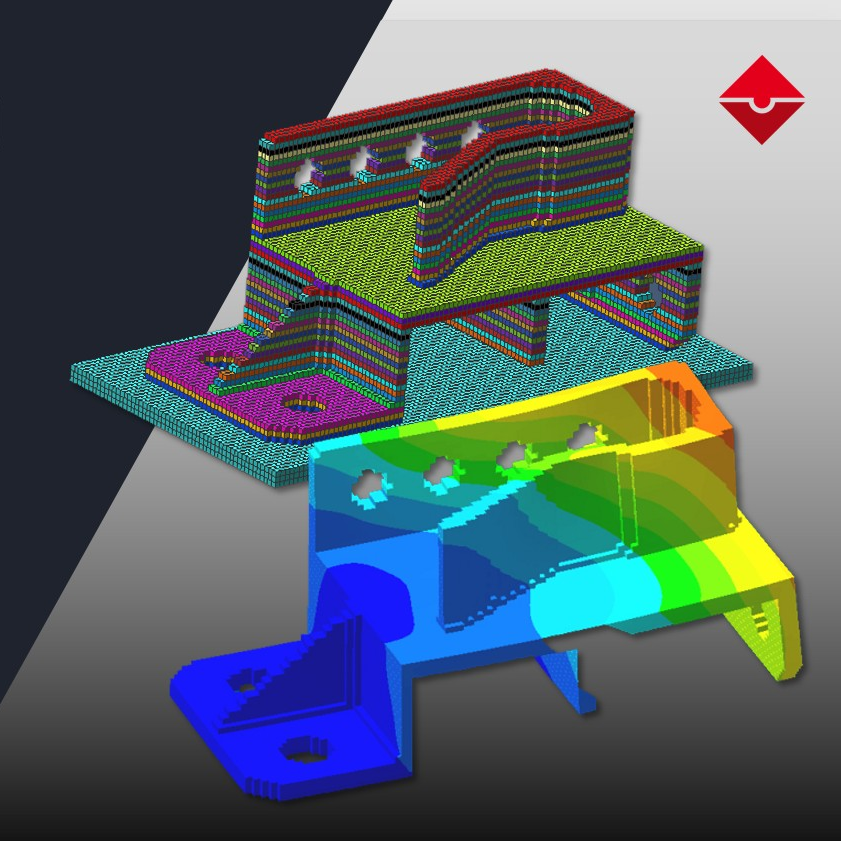

Finite Element simulation allows the prediction of the final distortions in Directed Energy Deposition (DED), Direct Metal Deposition (DMD) & Laser Metal Deposition (LMD) and their compensation to obtain an optimized DED component. With using advanced FEA software and HPC hardware, here at Enteknogarte, we solve the Direct Energy Deposition problems in detail to capture and analyzing the coupled thermal-mechanical response of the process, Investigating phase transformations during cooling process, Predicting distortions and residual stress build up during the process and Studying the influence of speed and power of heating sources on the process.

DED incorporates several metal 3D printing technologies that create parts by melting and fusing material as it is deposited, and is also known as 3D Laser Cladding, Wire Arc Additive Manufacturing (WAAM), Direct Metal Deposition (DMD), or Laser Metal Deposition (LMD). It’s typical fields of application are repairing and rebuilding damaged parts, but also manufacturing of new large metal parts that may not be possible with Powder Bed Fusion.

Our solution’s functionality helps you to answer challenges in Metal AM (Additive Manufacturing) Finite Element Simulation-based design and Optimization:

- Identify the best build orientation

- Determine and compensate final part distortionGenerate and optimize support structures

- Process window pre-scanning tool

- Powder coating

- Melt pool shape and dimensions

- Consolidated material porosity

- Surface roughness

- Thermal history as a function of deposition strategy

- Residual stresses

- Distortion during build process and after release

- Identify manufacturing issues such as cracks, layer offsets, recoater contact

- Predict the influence of several components in the build space

- Identify cold and hot spots due to thermal/thermo-mechanical simulation

- Examine conditions of highly elevated temperatures and pressures – HIP proces

Optimizing the design parameters for additive manufacturing

FEA Based Simulation enable our engineering team to gain insight into the microscale meltpool phenomena by performing full factorial studies with various process parameters for determine the best process parameters for any machine/material combination, and ensures the achievement of the highest integrity parts, as well as the expected microstructure and physical properties:

- Optimize and fine-tune their machine and material parameters.

- Develop new metal powders and metal AM (Additive Manufacturing ) materials and material specifications.

- Determine optimum machine/material parameters.

- Control microstructure and material properties.

- Manufacture using new metal powders faster and more efficiently.

- Reduce the number of experiments needed to qualify components.

- Mitigate risk while accelerating innovation.

- Analyze Porosity and Meltpools.

- Thermal history and microstructure information.

- Determines the percentage of porosity in a part due to lack of fusion.

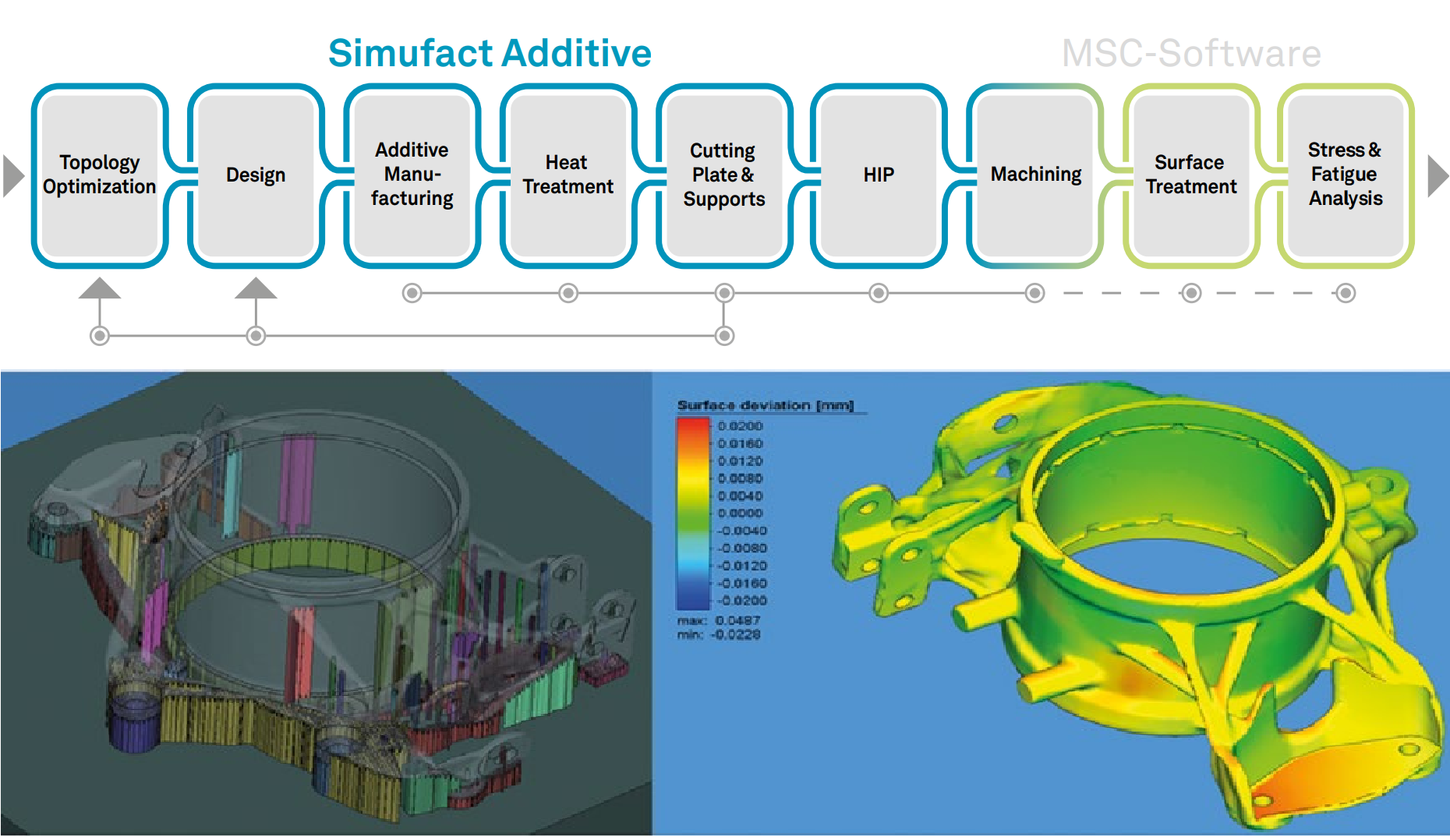

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae(Simufact, Digimat, Nastran, MSC APEX, Actran Acoustic solver), ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Directed Energy Deposition (DED), Direct Metal Deposition (DMD) & Laser Metal Deposition (LMD): Finite Element Simulation-Based Design

Finite Element Simulation of Powder Bed Fusion Processes

Metal Binder Jetting: Finite Element Simulation-Based Design

Additive Manufacturing of Plastics, Reinforced Polymers & Composites

Generative Design for Additive Manufacturing & Lattice Structures: Topology, Shape and Bead Optimization

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Additive Manufacturing and 3D Printing

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Vibration Fatigue Finite Element Simulation: Time & Frequency Domain

Finite Element Simulation of Heat Treatment

Finite Element Analysis of Durability and Fatigue Life

Finite Element Simulation of Laser Beam / Electron Beam Welding

Finite Element Welding Simulation: RSW, FSW, Arc, Electron and Laser Beam Welding

Metal Forming Simulation: FEA Based Design and Optimization

Casting: Finite Element and CFD Simulation Based Design

FEA Based Composite Material Design and Optimization: MSC Marc, Abaqus, Ansys, Digimat and LS-DYNA

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

In Silico Medical & Biomedical Device Testing: Finite Element & CFD Simulation and Design, Considering FDA & ASME V&V 40

Simulation of Plasma Based Devices: Microwave Plasma and RF Plasma Analysis with Coupling Particle in Cell (PIC), MHD, CFD and FEA Solvers

Electromagnetic Multiphysics FEA & CFD Based Simulation