Simulia Abaqus: Crash Test, Fracture & Damage, Blast & Explosion, Impact & Penetration, Thermal Analysis, Drop Test, Acoustics and Vibro-Acoustics

Many real-world engineering problems involve nonlinear behavior, such as material nonlinearity, contact, and large deformations. Abaqus is well-equipped to handle such scenarios and has a strong reputation for its ability to accurately simulate nonlinear responses. It is particularly suitable for modeling buckling, collapse, soft materials, and contact between deformable bodies. With Abaqus, we can simulate conductive and convective heat transfer, mass diffusion, acoustics, piezoelectricity, and electrochemistry either independently, sequentially coupled, or fully coupled with the stress analysis. What makes Abaqus uniquely powerful is its modularity. Abaqus can simulate rubber and polymers, reinforced concrete, glass and ceramics, crushable or resilient foam, and geotechnical materials like soils and rock.

Abaqus/Standard

Abaqus/Standard is indeed a powerful finite element solver that is specifically designed for simulating static and structural dynamic events. It offers a wide range of applications, including thermal-stress analysis, sealing evaluations, steady-state rolling simulation, fracture mechanics studies, heat transfer modeling, acoustics, pore pressure analysis, and more.

Abaqus/Standard excels in linear dynamics and includes the AMS eigensolver, which efficiently calculates natural frequencies for models with a large number of degrees of freedom. This makes it suitable for analyzing structural dynamics problems. The software provides a comprehensive library of element types to accommodate different modeling requirements, including solid elements, structural elements (shell, beam, truss, membrane), and elements for coupled simulations (thermal/structural, thermal/structural/electrical, piezoelectric, etc.).

In terms of material models, Abaqus/Standard offers a diverse range of options, ranging from linear elasticity and viscoelasticity to nonlinear viscoelasticity, isotropic and kinematic plasticity, damage and fracture mechanics, and even multiscale and mean-field homogenization for advanced material simulations.

Abaqus/Explicit

Abaqus/Explicit is an explicit-dynamic finite element solver specifically designed for simulating brief transient dynamic events. It is well-suited for scenarios involving highly nonlinear behavior, such as consumer electronics drop tests, automotive crashes, ballistic impacts, rolling of hot metal, and slow crushing of energy-absorbing structures.

Abaqus/Explicit excels in handling severely nonlinear behavior, including contact, which makes it attractive for simulating quasi-static events. It is particularly useful when dealing with situations where explicit time integration is necessary to capture the dynamic response accurately.

Abaqus/Explicit offers various analysis types, including nonlinear dynamic stress analysis, acoustics, multi-physics procedures for thermal/structural simulations, Discrete Element Method (DEM) for particle simulations, coupled Eulerian-Lagrangian simulation, and Smooth Particle Hydrodynamics (SPH).

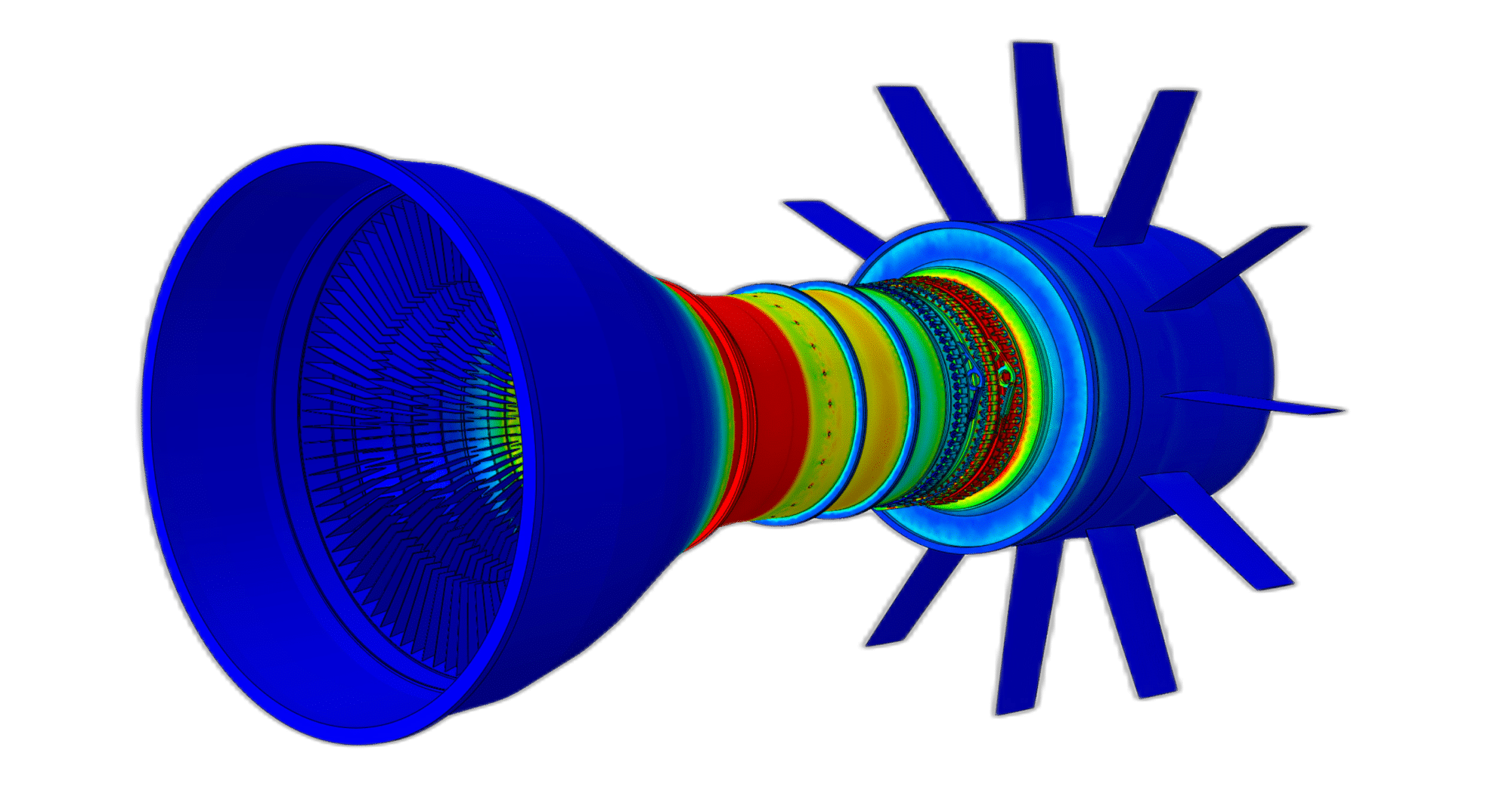

Abaqus Application in Aerospace Industry

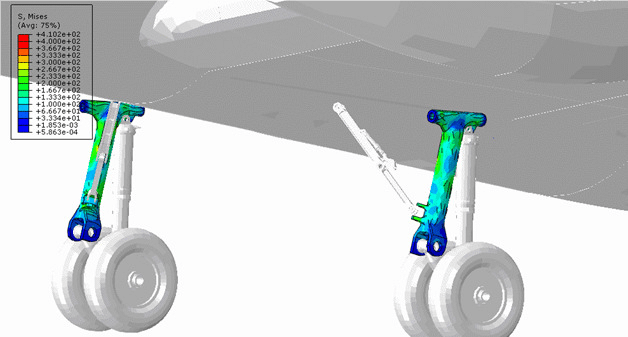

Structural Analysis: Abaqus is widely employed for structural analysis of aerospace components and structures. It can simulate the behavior of aircraft wings, fuselage, landing gear, and other structural components under different loading conditions. It helps assess the structural integrity, strength, and stiffness of aerospace structures, considering factors like material properties, nonlinear behavior, contact, and complex loading scenarios.

Fatigue and Fracture Analysis: Abaqus is used for fatigue and fracture analysis in aerospace applications. It can simulate the growth and propagation of cracks in aircraft structures, predict fatigue life, and assess the structural durability. By considering material properties, loading cycles, and stress concentrations, Abaqus helps engineers identify critical areas prone to crack initiation and optimize the design to enhance fatigue performance.

Impact and Crash Analysis: Aerospace structures are subject to various impact scenarios, such as bird strikes, foreign object damage, or emergency landings. Abaqus can simulate these events and assess the response of the structure, including contact, material failure, and energy absorption. It helps engineers evaluate the crashworthiness of aircraft components and optimize the design to enhance passenger safety.

Thermal Analysis: Abaqus is utilized for thermal analysis in aerospace applications, including evaluating heat transfer and thermal stresses in components exposed to high temperatures. It helps simulate thermal management systems, assess the behavior of materials under extreme thermal conditions, and optimize cooling strategies for engines, electronic components, and thermal protection systems.

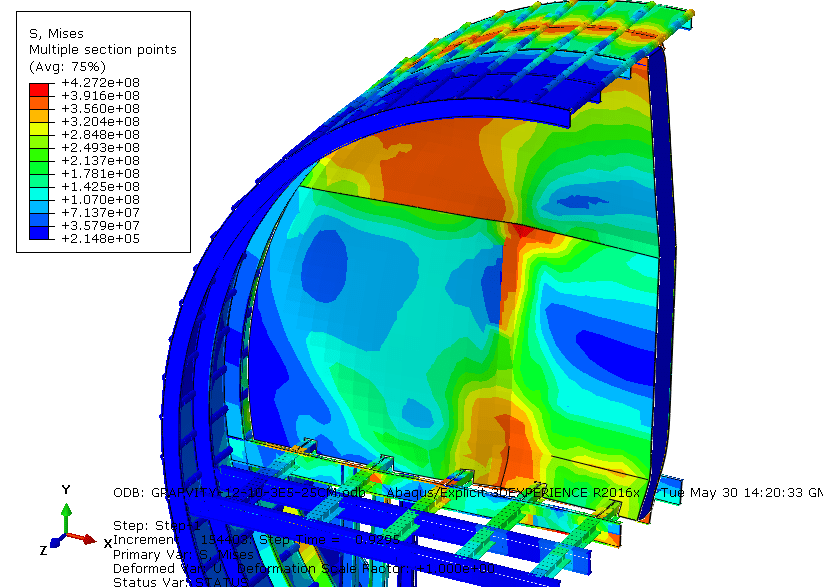

Composite Material Analysis: Composite materials play a crucial role in aerospace applications due to their high strength-to-weight ratio. Abaqus enables the simulation of composite structures, including modeling the behavior of composite laminates, delamination, progressive failure, and impact response.

Aeroelasticity: Abaqus in coupled with CFD solvers such as Siemens Star-CCM+ is used to analyze the aeroelastic behavior of aircraft, which involves the interaction between structural dynamics and aerodynamic forces. It helps assess the flutter, divergence, and control effectiveness of aircraft wings and control surfaces, ensuring stable flight characteristics.

Vibroacoustic Analysis: Abaqus is employed for vibroacoustic analysis to evaluate the noise and vibration characteristics of aerospace structures. It helps assess the structural response to acoustic loads, simulate noise propagation, and optimize designs to reduce noise levels in aircraft cabins and around the aircraft.

- Aerospace Seat Design: Federal Aviation Administration (FAA) and European Aviation Safety Agency (EASA)

Abaqus Application in Defence Industry

Structural Analysis: Abaqus is utilized for structural analysis of defense systems and components. It helps assess the structural integrity, strength, and performance of military vehicles, armored vehicles, submarines, ships, and aircraft. It can simulate the behavior of these structures under various loading conditions, including blast and impact events, and evaluate their response to ensure durability and survivability.

Ballistics and Penetration Analysis: Abaqus is employed for simulating ballistic impacts and penetration events. It helps assess the behavior of materials and structures when subjected to high-velocity projectiles, such as bullets, fragments, and missiles. Abaqus can model the interaction between the projectile and the target, including material failure, energy absorption, and penetration depth. This analysis aids in optimizing armor designs and evaluating their effectiveness against different threats.

Blast and Explosion Analysis: Defense systems often need to withstand blast and explosion events. Abaqus is used to simulate these scenarios and assess the response of structures and protective measures. It helps evaluate the structural integrity, deformation, and damage caused by blasts, including the interaction between shock waves, shrapnel, and the surrounding environment.

Impact and Crashworthiness Analysis: Abaqus is utilized for impact and crashworthiness analysis in defense applications. It helps evaluate the response of military vehicles, aircraft, and ships to crash and collision events. By simulating the interaction between different components, materials, and structures, Abaqus assists in optimizing designs to enhance occupant safety and structural integrity during accidents.

Fluid-Structure Interaction (FSI): Abaqus in coupled with advanced CFD solvers such as Siemens Star-CCM+ is used for fluid-structure interaction analysis in defense systems. It helps simulate the interaction between fluids (such as water or air) and structures, including submarines, ships, and underwater vehicles. Abaqus enables the study of hydrodynamic effects, such as fluid forces, fluid-structure interaction, and wave-induced loads, to optimize designs for performance and stability with coupling with CFD solvers or using special purpose methods.

Material Modeling and Behavior: Abaqus offers a wide range of material models that are crucial in defense applications. It can simulate the behavior of materials under extreme conditions, such as high temperatures, high strain rates, and complex loading scenarios. Abaqus helps analyze the performance of armor materials, composites, explosives, propellants, and other specialized materials used in defense systems.

Dynamic Response and Vibration Analysis: Abaqus is employed for analyzing the dynamic response and vibration characteristics of defense systems. It aids in evaluating the structural dynamics, stability, and natural frequencies of structures subjected to operational loads, including vibrations induced by engines, rotating machinery, or external excitations. This analysis helps optimize designs for performance and reduce potential failures.

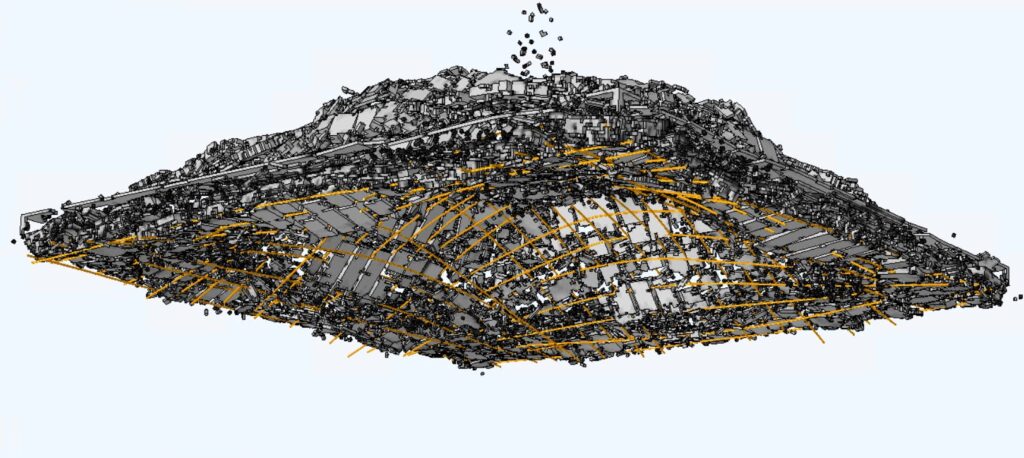

Abaqus Applications in Civil Engineering, Particularly in the Fields of Soil Mechanics, Rock Mechanics, Geotechnical Engineering, Earthquake Engineering, and Seismic Analysis:

Soil Mechanics and Geotechnical Engineering: Abaqus is employed for analyzing the behavior of soils and geotechnical structures. It helps simulate soil-structure interaction, soil consolidation, and settlement analysis. Abaqus can model complex soil behaviors such as nonlinear soil behavior, soil plasticity, and soil-structure interaction effects, enabling engineers to assess the stability and performance of foundations, retaining walls, embankments, tunnels, and deep excavation projects.

Rock Mechanics: Abaqus is used to simulate the behavior of rocks and rock structures. It helps analyze rock slopes, underground excavations, rock foundations, and stability assessments. Abaqus can model the nonlinear behavior of rocks, including rock mass behavior, jointed rock, and rock fracture mechanics. It enables engineers to assess the stability of rock structures and optimize designs for mining, tunneling, and geotechnical projects.

Seismic Analysis and Earthquake Engineering: Abaqus is employed for seismic analysis and earthquake engineering applications. It helps simulate the response of structures subjected to seismic forces and assess their seismic performance. Abaqus can model soil-structure interaction, nonlinear behavior of materials, and dynamic response analysis. It enables engineers to evaluate the structural response, deformation, and failure mechanisms of buildings, bridges, dams, and other infrastructure under earthquake loads.

Dynamic Soil-Structure Interaction: Abaqus enables the analysis of dynamic soil-structure interaction (DSSI) problems. It helps simulate the complex interaction between the dynamic behavior of structures and the surrounding soil. Abaqus can model the coupling effects between the soil and structure, including soil-structure interaction during earthquakes or dynamic loading conditions. It assists in assessing the dynamic response and stability of structures in varying soil conditions.

Geotechnical Material Modeling: Abaqus offers a range of material models specifically designed for geotechnical materials. It includes models for soils, rocks, and other geotechnical materials with nonlinear behavior, such as plasticity, creep, and rate-dependent properties. Abaqus helps engineers accurately represent the mechanical properties and behavior of geotechnical materials in their numerical simulations.

Ground Improvement Techniques: Abaqus is utilized to analyze and optimize ground improvement techniques in geotechnical engineering. It helps simulate the behavior of various ground improvement methods, such as soil consolidation, deep soil mixing, stone columns, and geosynthetics. Engineers can assess the effectiveness of these techniques in improving soil properties, enhancing stability, and reducing settlement.

Geotechnical Failure Analysis: Abaqus aids in the analysis of geotechnical failures, such as slope failures, retaining wall failures, and foundation failures. It enables engineers to simulate and understand the failure mechanisms, identify critical failure zones, and evaluate the factors contributing to failure. This analysis helps in designing appropriate mitigation measures and optimizing geotechnical structures.

Abaqus Applications in insilico Testing and the Medical and Biomedical Industry:

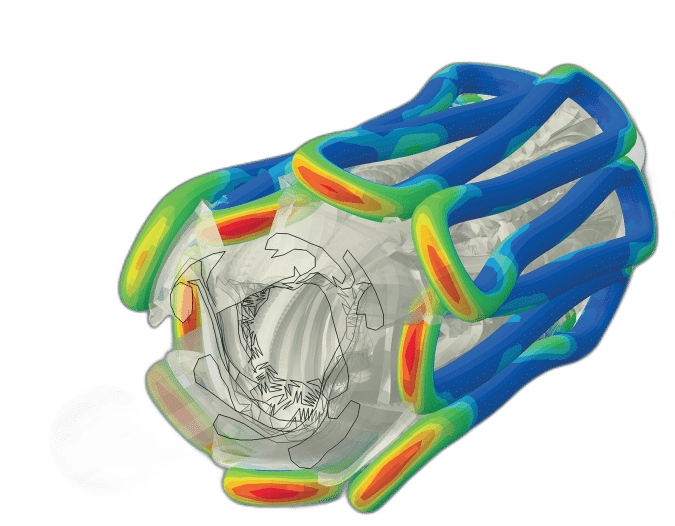

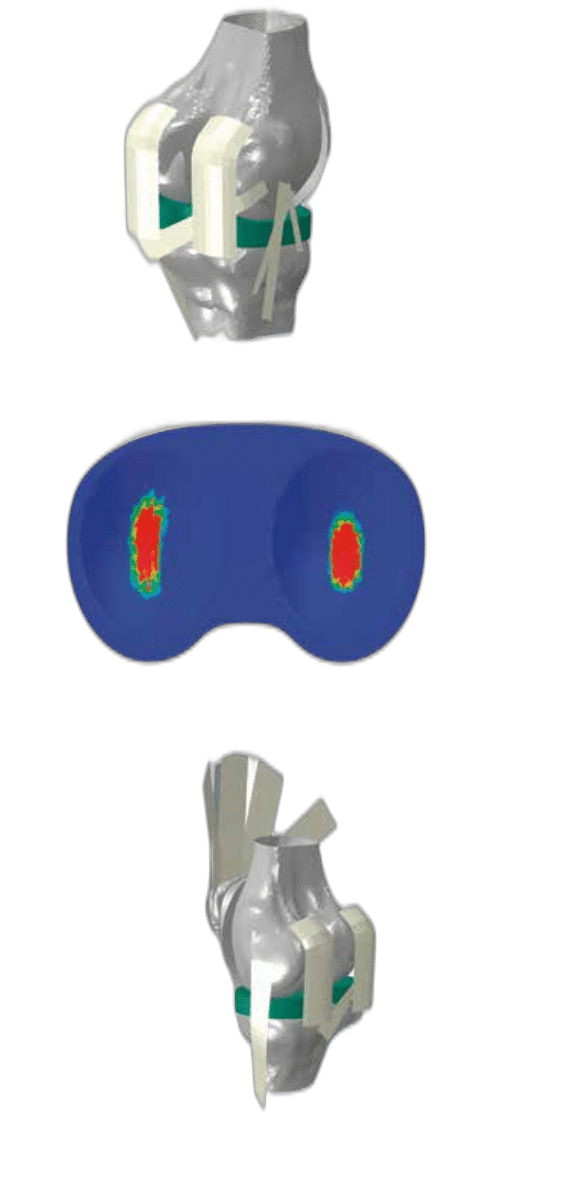

Biomechanics and Bioengineering: Abaqus is used to simulate and analyze the mechanical behavior of biological tissues, implants, and medical devices. It helps in studying the performance and safety of implants, such as orthopedic implants, cardiovascular stents, and dental implants. Abaqus can model the complex behavior of biological tissues, including their nonlinear, anisotropic, and time-dependent properties. It enables engineers and researchers to evaluate the mechanical response, stress distribution, deformation, and failure mechanisms of biological structures and implants under various loading conditions.

Computational Fluid Dynamics (CFD): Abaqus can coupled with CFD softwares such as Siemens Star-ccm+ that is very important to medical and biomedical applications. It helps simulate fluid flow, heat transfer, and mass transport in biological systems, such as blood flow in arteries, respiratory airflow, drug delivery, and fluid dynamics in medical devices. Abaqus – Start-ccm+ coupling can model fluid-structure interaction, multiphase flow, and complex flow phenomena. It enables engineers and researchers to study the fluid behavior, optimize designs, and analyze the performance of biomedical devices and systems.

Tissue Engineering and Regenerative Medicine: Abaqus is employed in tissue engineering and regenerative medicine to simulate the growth and behavior of biological tissues and engineered constructs. It helps analyze scaffold materials, cell behavior, tissue regeneration, and the mechanical properties of tissue-engineered constructs. Abaqus can model the mechanical stimuli on cells and tissues, cell migration, and tissue growth. It assists researchers in optimizing the design and fabrication of tissue-engineered scaffolds and evaluating their mechanical functionality.

Biomechanical Modeling and Simulation: Abaqus enables the modeling and simulation of complex biomechanical systems, such as human joints, bones, muscles, and ligaments. It helps in analyzing human movement, joint mechanics, and the interaction between muscles and skeletal structures. Abaqus can model musculoskeletal dynamics, contact interactions, and soft tissue behavior. It assists in studying human biomechanics, optimizing orthopedic treatments, and designing prosthetic devices.

Virtual Surgical Planning: Abaqus is utilized in virtual surgical planning and simulation. It helps simulate surgical procedures, such as orthopedic surgeries, craniofacial surgeries, and maxillofacial surgeries. Abaqus can model the interactions between surgical instruments, implants, and anatomical structures. It enables surgeons and researchers to plan surgeries, assess surgical outcomes, and evaluate the mechanical performance of surgical procedures.

Medical Device Design and Analysis: Abaqus is employed in the design and analysis of medical devices, such as pacemakers, prosthetic limbs, medical implants, and surgical instruments. It helps in assessing the mechanical integrity, durability, and performance of these devices under various loading conditions. Abaqus can model the material behavior, contact interactions, and complex geometries of medical devices. It assists in optimizing device designs, evaluating safety factors, and meeting regulatory requirements.

Abaqus Applications in the Oil, Gas, and Petrochemical Industry:

Structural Analysis: Abaqus is used for structural analysis of oil and gas infrastructure, such as offshore platforms, drilling rigs, pipelines, storage tanks, and process equipment. It helps in evaluating the structural integrity, strength, and reliability of these components under different loading conditions, including wave loads, wind loads, seismic loads, and thermal effects. Abaqus can model complex geometries, material nonlinearities, contact interactions, and large deformations to ensure the safe and efficient operation of these structures.

Geotechnical Analysis: Abaqus is employed for geotechnical analysis in the oil and gas industry. It helps in simulating soil-structure interaction, foundation behavior, and stability analysis of onshore and offshore structures. Abaqus can model various soil behaviors, including nonlinear soil constitutive models, consolidation, and dynamic soil response. It assists in assessing the foundation performance, settlement, bearing capacity, and soil liquefaction potential for infrastructure projects.

Fluid-Structure Interaction (FSI): Abaqus offers capabilities for fluid-structure interaction analysis with coupling with CFD softwares such as Siemens Star-ccm+, which is crucial in simulating the behavior of structures subjected to fluid flow, such as pipelines, risers, and offshore structures. It helps in evaluating the structural response to fluid-induced forces, such as vortex-induced vibrations, wave loads, and hydrodynamic pressures. Abaqus can model the coupling between structural deformations and fluid flow, allowing engineers to assess the dynamic behavior and integrity of these systems.

Heat Transfer and Thermal Analysis: Abaqus is utilized for heat transfer and thermal analysis in the petrochemical industry. It helps in simulating heat conduction, convection, and radiation processes in equipment and systems, such as heat exchangers, furnaces, reactors, and pipelines. Abaqus can model complex thermal behaviors, including temperature-dependent material properties, phase change, and thermal stresses. It assists in optimizing thermal performance, predicting hotspots, and ensuring the safe operation of these systems.

Failure Analysis and Fracture Mechanics: Abaqus is used for failure analysis and fracture mechanics in the oil, gas, and petrochemical industry. It helps in predicting and assessing the initiation and propagation of cracks and fractures in structural components and piping systems. Abaqus can model crack growth, fatigue, brittle fracture, and other failure mechanisms. It assists in evaluating the remaining life of aging infrastructure, optimizing maintenance strategies, and ensuring the safety and reliability of these systems.

Multiphysics Analysis: Abaqus enables multiphysics simulations with coupling with CFD softwares such as Siemens Star-ccm+ in the oil, gas, and petrochemical industry, where multiple physical phenomena interact with each other. It can combine structural analysis with fluid flow, heat transfer, and other coupled physics. This capability is particularly useful for simulating complex systems, such as multiphase flow in pipelines, thermal-hydraulic behavior in reactors, and coupled fluid-structure interactions in offshore platforms.

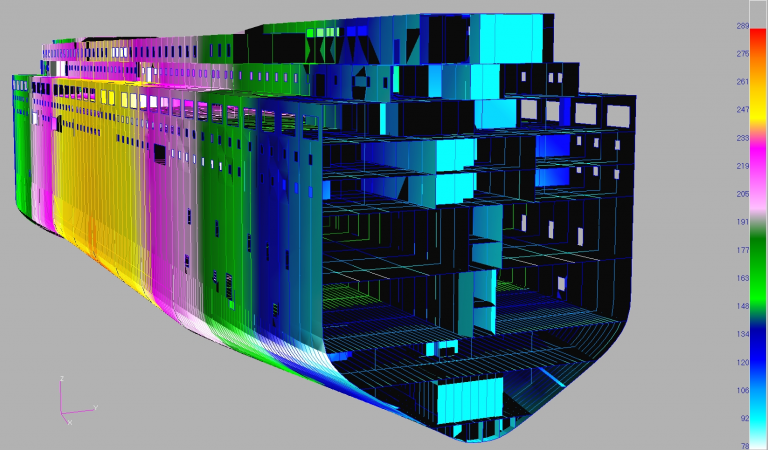

Abaqus Applications in the Marine and Shipbuilding Industry:

Structural Analysis: Abaqus is used for structural analysis of ship components and structures, including hulls, decks, bulkheads, and superstructures. It helps in evaluating the strength, stiffness, and integrity of ship structures under different loading conditions, such as waves, wind, and cargo loads. Abaqus can model the complex behavior of materials, including nonlinearities, large deformations, and material failure. It enables engineers to assess structural safety, optimize designs, and meet regulatory requirements.

Hydrodynamic Analysis: Abaqus offers coupling with CFD softwares such as Siemens Star-ccm+ to enable advanced hydrodynamic analysis, allowing engineers to study the behavior of ships in water, including resistance, propulsion, maneuverability, and seakeeping characteristics. It can simulate the interaction between the ship and water, accounting for wave loads, fluid flow, and hydrodynamic forces. Abaqus and Star-ccm+ coupling assists in evaluating the performance of ship designs, optimizing hull shapes, and assessing the impact of design changes on hydrodynamic performance.

Fatigue and Durability Analysis: Abaqus is used to assess the fatigue life and durability of ship structures subjected to cyclic loading, such as wave-induced loads and vibrations. It helps in predicting the accumulation of fatigue damage, identifying critical areas prone to fatigue failure, and optimizing the design to enhance the fatigue resistance of ship structures. Abaqus can model the cyclic behavior of materials, crack propagation, and fatigue failure mechanisms.

Welding and Joining Analysis: Abaqus is employed to analyze welding and joining processes in shipbuilding, including the behavior of welded joints, connections, and structural assemblies. It helps in assessing the integrity and strength of welded structures, predicting residual stresses, and evaluating the performance of different welding techniques. Abaqus can simulate the heat transfer, thermal distortion, and mechanical behavior of welded joints, enabling engineers to optimize welding parameters and improve structural reliability.

Impact and Crashworthiness Analysis: Abaqus is utilized to analyze the impact and crashworthiness of ships, including collision scenarios, grounding events, and accidental impacts. It helps in studying the structural response, energy absorption, and damage propagation during such events. Abaqus can model the nonlinear behavior of materials, contact interactions, and large deformations, enabling engineers to assess the structural integrity and safety of ships under impact loading.

Noise and Vibration Analysis: Abaqus offers capabilities for noise and vibration analysis, allowing engineers to evaluate the acoustic and vibration performance of ship structures and systems. It helps in predicting noise levels, structural vibrations, and the transmission of vibrations through ship structures. Abaqus can model the dynamic behavior of structures, fluid-structure interaction with coupling with CFD softwares such as Star-ccm+, and vibro-acoustic phenomena. It assists in optimizing designs to reduce noise and vibration levels, enhancing passenger comfort and crew safety.

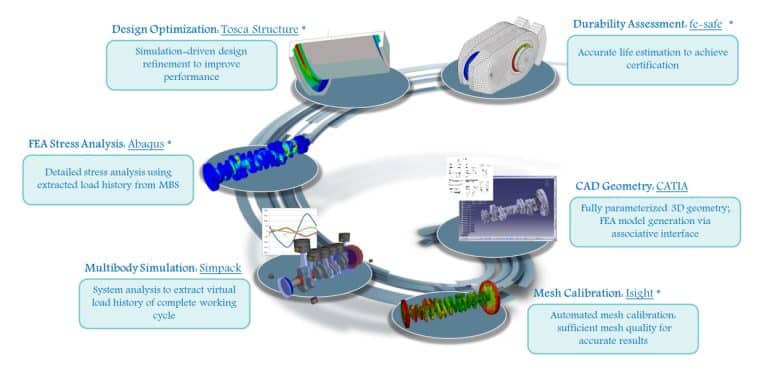

Abaqus Applications In The Automotive Industry:

Structural Analysis: Abaqus is employed for structural analysis in the automotive industry to evaluate the performance, safety, and durability of vehicle components and structures. It helps in simulating and optimizing the behavior of chassis, body frames, suspension systems, crashworthiness, and occupant safety.

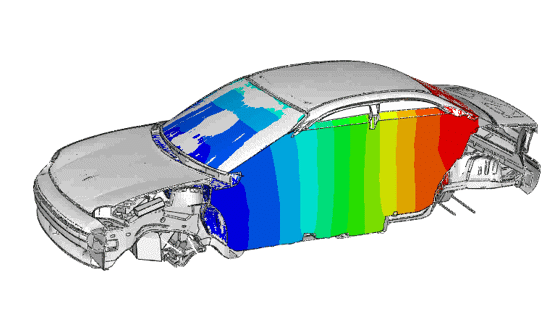

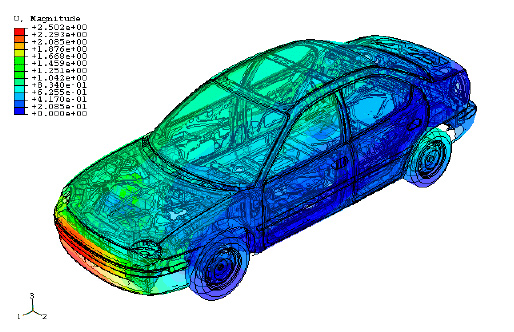

Crashworthiness and Occupant Safety: Abaqus is extensively used for crash simulations to assess the crashworthiness and occupant safety of vehicles. It helps in predicting the response of the vehicle structure and occupants during frontal, side, and rear-end collisions. Abaqus can model the deformation and failure behavior of materials, complex contact and separation, airbag deployment, and restraint systems. It aids in optimizing vehicle designs to meet safety regulations, reduce weight, and enhance occupant protection.

NVH Analysis: Abaqus is utilized for noise, vibration, and harshness (NVH) analysis in the automotive industry. It helps in simulating and optimizing the acoustic and vibration performance of vehicles. Abaqus can model structural vibrations, modal analysis, dynamic response, and sound transmission to predict and control noise and vibration levels. It assists in optimizing vehicle designs for improved ride comfort, reduced noise levels, and enhanced overall vehicle performance.

Durability and Fatigue Analysis: Abaqus is used for durability and fatigue analysis in the automotive industry to assess the lifespan and structural integrity of vehicle components subjected to cyclic loading. It helps in predicting fatigue life, crack initiation, and propagation in critical parts such as engine components, suspension systems, and drivetrain components. Abaqus can model material fatigue properties, load spectra, and environmental conditions to optimize designs and improve component durability.

Thermal Analysis: Abaqus finds application in thermal analysis for automotive components and systems. It helps in simulating and optimizing the thermal behavior of engines, exhaust systems, brakes, cooling systems, and other heat-generating components. Abaqus can model heat transfer, thermal stresses, and temperature distribution to evaluate thermal performance, optimize designs, and ensure the reliability of automotive systems.

Manufacturing and Forming Processes: Abaqus is used in the automotive industry to simulate various manufacturing and forming processes, such as stamping, forging, molding, and joining. It helps in predicting the behavior of materials during these processes, including material flow, deformation, residual stresses, and springback. Abaqus assists in optimizing manufacturing processes, reducing defects, and improving the overall quality of automotive components.

- Seat Design: The ability to predict the comfort of innovative seat designs using a combination of advanced design and simulation tools, a library of human models with our team experience in CFD (Siemens Start-ccm+, Ansys Fluent and OpenFoam) and FEA (Ansys LS-DYNA, Simulia Abaqus, ESI Pam-Crash and Altair RADIOSS) simulation software with integrated Artificial Intelligence and Machine Learning for innovative design, can help manufacturers to create seats that provide a superior driving experience for their customers.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae(Simufact, Digimat, Nastran, MSC APEX, Actran Acoustic solver), ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Crash Test and Crashworthiness

Blast Resistance with Protection Against Ballistic Attacks

Seat Design: Finite Element and CFD Simulation for Static & Dynamic Comfort, Whiplash, Acoustic & Thermal Comfort, Crash Test

Structural Dynamics: Coupling CFD, MBD, FEA and 1D Systems Simulation Software

Finite Element Welding Simulation: RSW, FSW, Arc, Electron and Laser Beam Welding

Metal Forming Simulation: FEA Based Design and Optimization

Finite Element Analysis of Durability and Fatigue Life

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Casting: Finite Element and CFD Simulation Based Design

Additive Manufacturing and 3D Printing

Rotors Aerodynamic Simulation via Coupled FEA (MBD)/CFD Method: Aeroelastic Behavior Assessment

eVTOL (Electric Vertical Take-Off and Landing) & UAM (Urban Air Mobility)

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

FEA Based Composite Material Design and Optimization: MSC Marc, Abaqus, Ansys, Digimat and LS-DYNA

CFD and FEA in Civil Engineering: Seismic Design, Earthquake, Tunnel, Dam, Concrete Structures and Geotechnical Multiphysics Simulation

Marine and Shipbuilding Industry: Finite Element and CFD Based Simulation and Design

In Silico Medical & Biomedical Device Testing: Finite Element & CFD Simulation and Design, Considering FDA & ASME V&V 40

Electromagnetic Multiphysics FEA & CFD Based Simulation

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation

Hydrodynamics: Coupled CFD and FEA simulation for FSI Analysis

Fluid Structure Interaction (FSI)

Finite element analysis of concrete: Discrete cracking, Smeared crack and XFEM for concrete fracture and damage Simulation

Full Vehicle MultiBody Dynamics Simulation: Car Ride, Driveline, Engine and Tire MBD

Multibody Dynamics

NVH & Acoustics for Hybrid & Electric Vehicles