Fluid Structure Interaction (FSI)

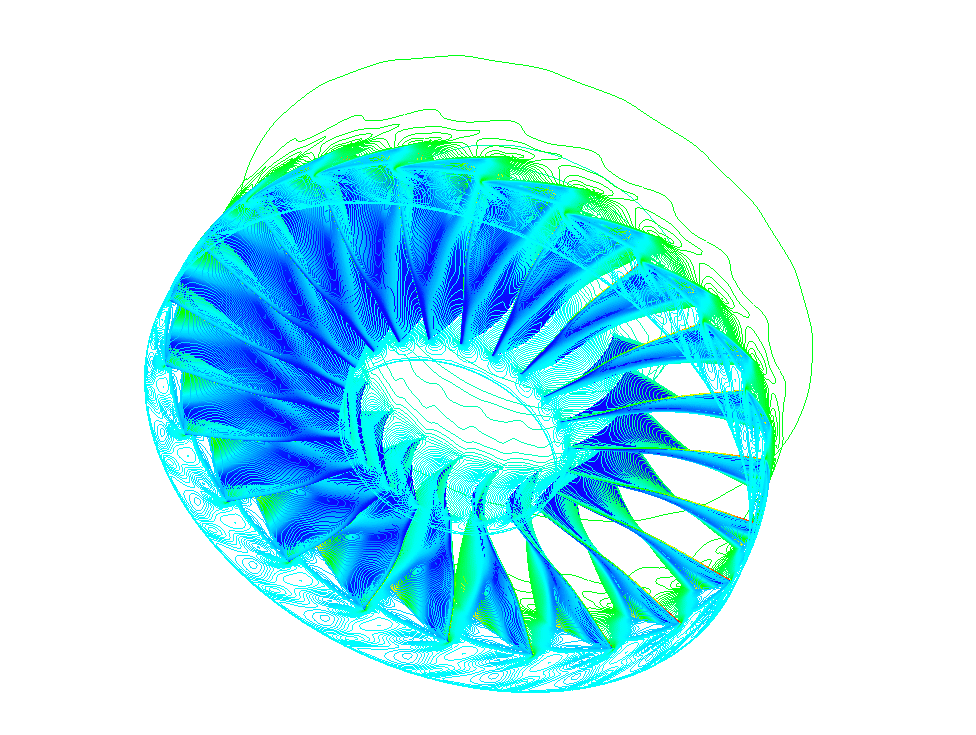

Fluid Structure Interaction (FSI) calculations allow the mutual interaction between a flowing fluid and adjacent bodies to be calculated. This is necessary since all real structures are flexible, especially those that are large or subject to high fluid loads. The body forces generated by fluids flowing are highly sensitive to the shape and curvature of adjacent surfaces. By coupling a CFD solver and the FEA solver, the deformation of a body resulting from the fluid loads and the subsequent modification of the flow field due to the newly deformed geometry can be computed iteratively.

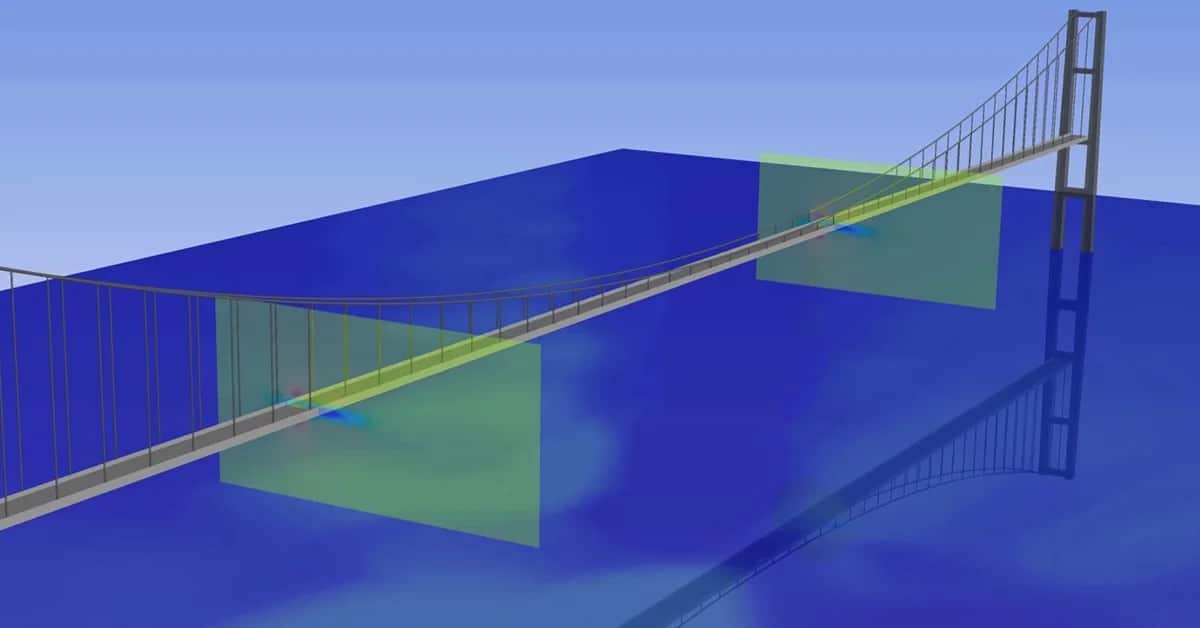

This technique allows aeroelastic instabilities such as flutter, to be detected and avoided early in the design cycle. Similarly, where structures are subjected to cyclic fatigue loading, such as rotor-stator interaction in compressor applications or vortex shedding around civil structures, these load effects can be accurately quantified to allow the fatigue life of the structure to be assessed.

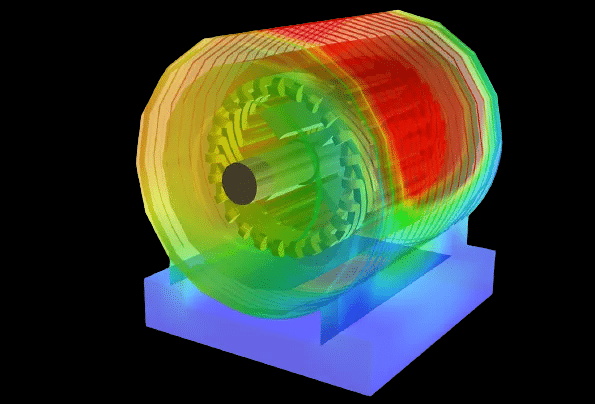

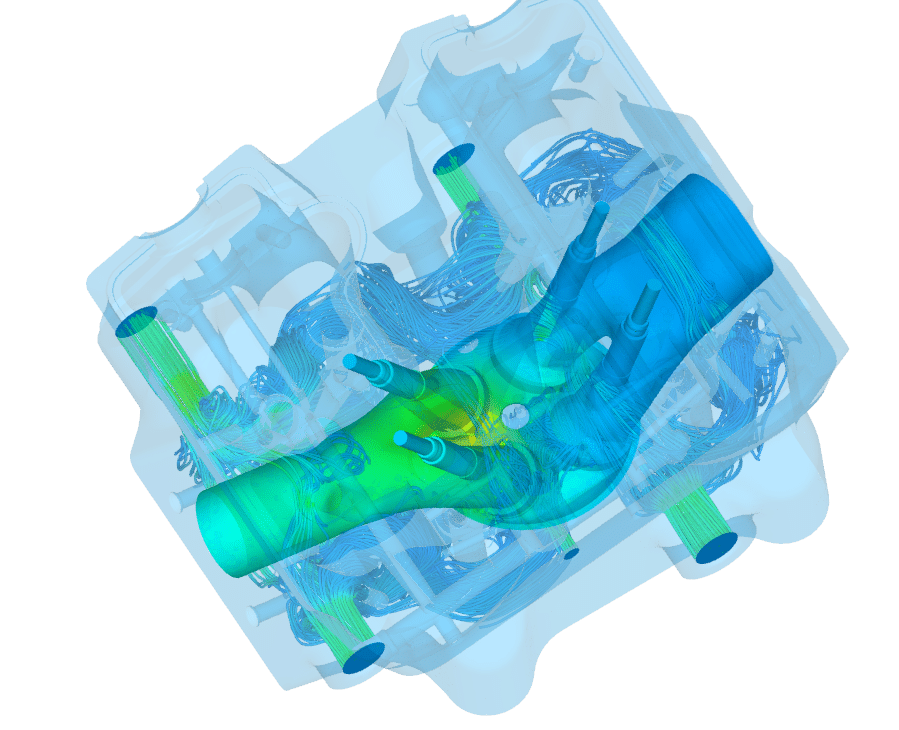

Simulating the thermal performance of a product early in the design phase can save large amounts of time and money by getting the design of the early prototypes right from a thermal management standpoint, thus reducing the need for additional prototypes that might otherwise be required to diagnose and correct thermal issues. Simple computational fluid dynamics (CFD) software can be used to analyze thermal issues such as determining how heat is transferred through a fluid. But many problems are more complex, such as those that involve multiple mechanisms of heat transfer, where heat is transferred through both solids and structures.

Cases in which the fluids and structures involved in heat flow are closely coupled, so that thermal deflection of the structures affects the fluid flow, are also challenging. Engineers often need to understand how heat is transferred by a number of different mechanisms through a complicated interconnected system in order to understand how their product or process will perform under a given set of conditions. This point is one of the applications of FSI simulation with Coupled CFD-FEA method.

As in isolated FEA and CFD one of the most profound benefits of FSI analysis is the ability to conduct comprehensive, multi-point optimization of designs. This process allows us to optimise a design to a given set of performance parameters and can be used to tune frequencies, or maximize fatigue life or avoid harmful resonance.

One-Way FSI: Coupling CFD and FEA

Solving thermal problems with CHT limits the engineer to the physical models that are contained within the CFD solver. More complex problems, such as those involving complex multimaterial structures or more accurate heat transfer coefficient (HTC) boundary conditions, can be solved by linking the CFD solver to a structural solver. Transferring solid temperature fields from CFD CHT simulations to a structural thermal system make it possible to use advantage of FSI simulation. The temperatures or HTCs calculated by CFD, and also the surface loads if desired, calculated by the CFD solver are transferred to the structural finite element analysis (FEA) code and FEA code calculates the heat transfer and thermal fields in the structure as well as thermal–mechanical stresses. A characteristic of a one-way fluid structure interaction (FSI) solution is that the stresses and deformations calculated in the structural solver are not passed back to CFD to update the mesh and recalculate the flow.

Enteknograte’s engineers also used the shape optimization methods to optimize heat transfer based on problem conditions. Also, we use Simulia FE-SAFE, Ansys nCode DesignLife and FEMFAT for fatigue analysis to calculate differenet type of fatigue safety factors based on the results of thermo-machnical simulations. The new design delivers the long life and high quality that the Enteknograte’s customers have come to expect.

Two-Way FSI: Two-way coupled CFD and structural (FEA)–Thermal simulation

Applications such as leakage paths and thin film flows where thermal-stress induced structural deformation affects fluid flow present an even more difficult simulation challenge. These applications can be simulated with two-way coupled CFD and structural thermal simulation. With this approach, the fluid flow solution is applied to the structure and the deformation of the structure is in turn applied to the fluid flow at each time step of the simulation. Two-way CFD and structural thermal simulation made it possible to set up a transient simulation that simultaneously solves the heat transfer coefficients (HTC) and near wall temperatures in the fluid

Failure to properly manage thermal performance can lead to inefficient energy use, uncomfortable or even unsafe temperatures, suboptimal performance and lower than expected product life. Engineering simulation is essential to diagnosing and evaluating solutions for thermal problems early in the design process when they can be corrected at the least possible cost and time. Enteknograte’s engineering team cane accurately predict thermal performance across a wide range of operating conditions with deep knowledge in FEA and CFD and coupling them, enable us the capabilities required to address the most difficult thermal design challenges:

- Thermal shock resistance for brittle materials immersed in a fluid.

- Cracking mechanism in materials subject to high temperature gradients

- Furnace or burner failures

- Radiators and heat exchanger flow balance

- Cross flow heat exchanger liquid gas

- Pins and turbolators pressure drop and trade-offs

- Kilns transient analysis

- Thermal shocks on Solar panels

- Cooling jackets, cooling holes position and dimensions

- Automotive exhaust, turbogas exhaust

- Defrosting ducts for automotive and home appliances

- Lamps, automotive headlights

Enteknograte engineering team use advanced CAE software with special features for mixing the best of both FEA tools and CFD solvers: CFD codes such as Ansys Fluent, Siemens StarCCM+ and FEA Codes such as ABAQUS, Nastran, LS-Dyna and the industry-leading fatigue Simulation technology such as Simulia FE-SAFE, Ansys Ncode Design Life to calculate fatigue life and MSC Actran and ESI VA One for Acoustics and VibroAcoustics simulations.

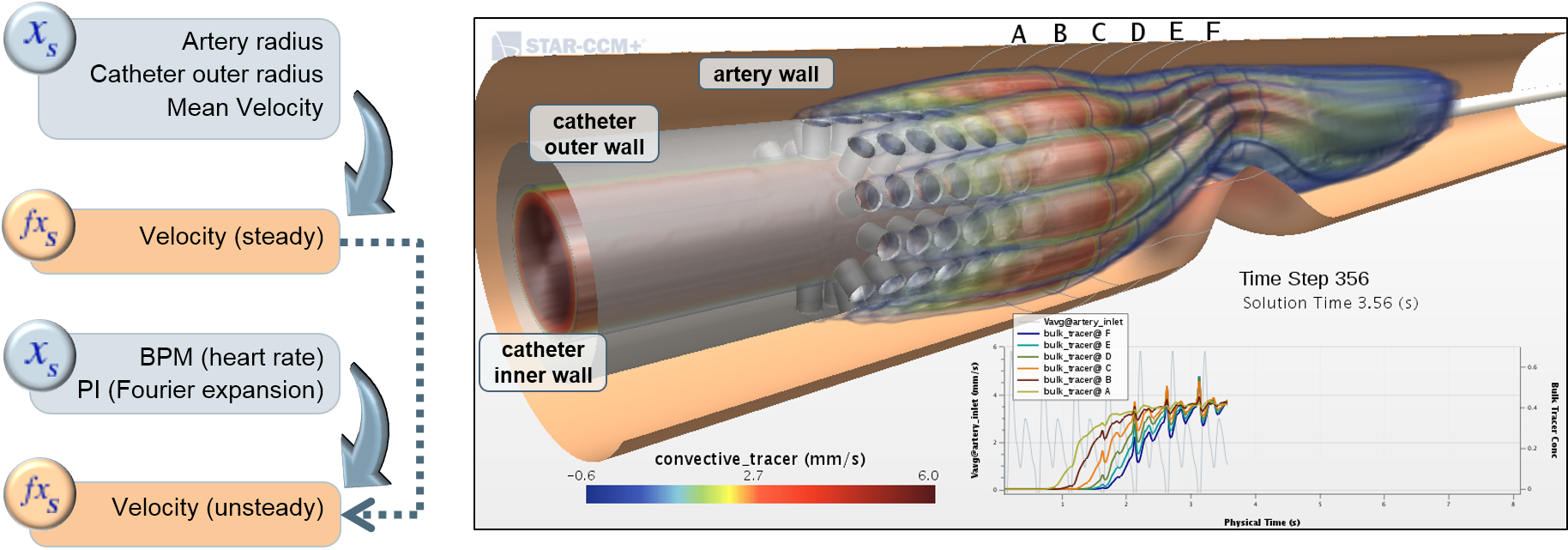

With combination of deep knowledge and experience in sophisticated FEA and CFD based simulation and design tools and coupling with 1D System modeilng Software such as Matlab Simulink, Enteknograte engineers can solve any problem with any level of complexity in Medical and Biomedical applications Design and Optimization.

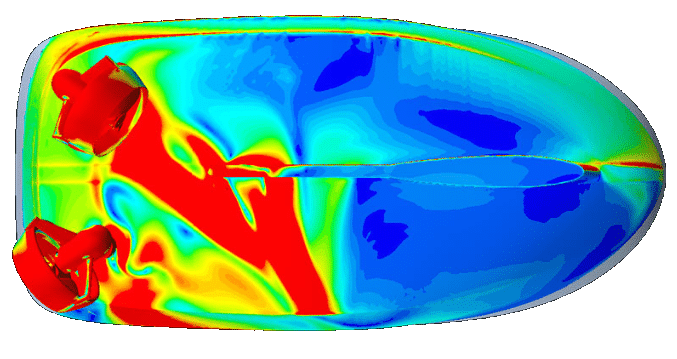

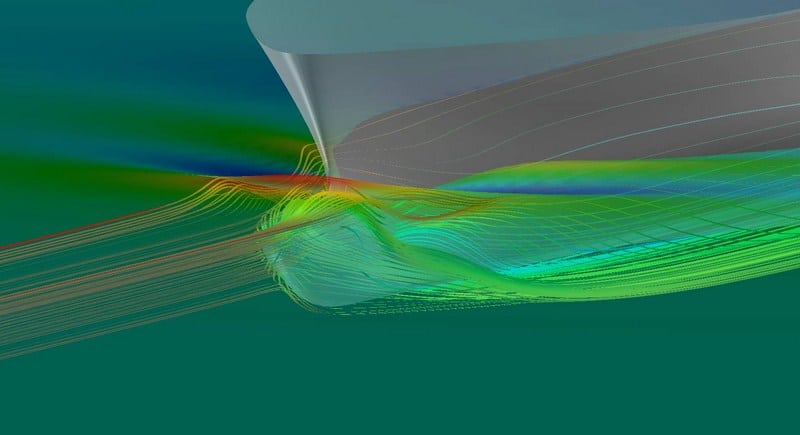

FEA and CFD based Design and Optimization for Marine and Shipbuilding Industry

From the design and manufacture of small recreational crafts to the large oil tankers, using FEA and CFD based simulation, Enteknograte assisting shipbuilders and boat designers to develop higher performing, safer and lower cost vessels. Through the application of simulation technology and consulting services, Enteknograte supports Marine and Shipbuilding Industry solve complex engineering challenges and mitigate environmental risks associated with seagoing loads including structural, hydrodynamics, vibro-acoustics, thermal and fatigue.

Enteknograte has a staff of highly qualified engineers and naval architects that has maintained its leading-edge know-how and development skills. Our Engineers have a rich experience in computer modeling of structures and the application of linear and non-linear (implicit and explicit) finite element codes and using advanced CFD tools in coupled with FEA to precise and real-time modeling of complicated floating structures that experience FSI for a wide range of engineering problems. Enteknograte has a proven track-record in structural analysis, marine investigation and surveying. We have a comprehensive experience in use of the most advanced computational tools to meet almost any analysis need:

- Global and detailed direct structural assessment (FEM, Finite Element Method), including verification of Fiber-Reinforced Polymer (FRP) structures for boat.

- Performance prediction based on Computation Fluid Dynamics (CFD) analysis.

- CFD studies for optimization of appendages and other elements.

- Fatigue assessment studies.

- Modal and vibration analyses.

- Seakeeping and seaworthiness assessment.

- Maneuvering studies.

- Simulation and evaluation of systems

- Marine surveying and reporting

- Damage surveys and investigations

- Tie-down structural calculations and approval

- Collision Investigation, modeling and analysis

Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

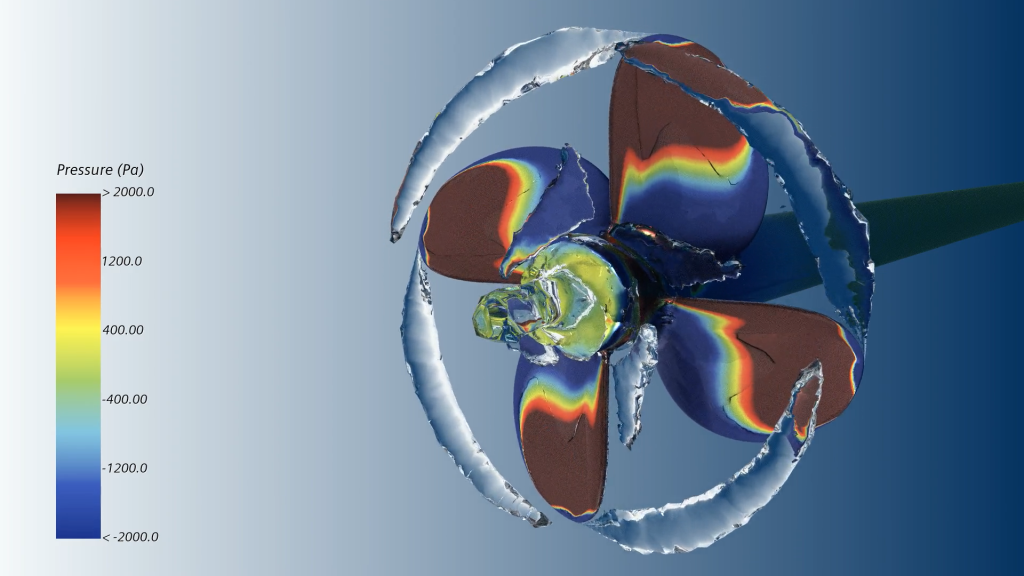

Hydrodynamics is a common application of CFD and a main core of Enteknograte expertise. CFD allows the steady-state and transient hydrodynamics of hydrofoils, submersible vehicles, propellers, impellers, marine structures and marine plant to be computed with extremely high levels of accuracy. System properties such as mass flow rates and pressure drops and fluid dynamic forces such as lift, drag and pitching moment can be readily calculated in addition to the wake effects. This data can be used directly for design purposes or as in input to a detailed stress analysis.

Hydrodynamics simulation and optimization is one of the Enteknograte’s core expertise. Deep knowledge and experienece combining with advanced CFD and FEA software enable us to handle any problem with any level of complexity in very short time. We Use CFD tools such as Numeca Fine/Marine, Ansys Fluent, Siemens Star-ccm+ and FEA Tools such as Abaqus, Nastran and LS-DYNA with combination of very experienced engineers to help our customers in:

|

|

FEA and CFD based Simulation and Design for Medical and Biomedical Applications

FEA and CFD based Simulation design and analysis is playing an increasingly significant role in the development of medical devices, saving development costs by optimizing device performance and reliability, reducing benchtop tests and clinical trials, and helping to speed the regulatory approval process. Developing increasingly complex medical devices requires increasingly capable tools for simulation and testing. Our deep portfolio of simulation and testing solutions allows medical device developers to generate digital evidence of device performance across a range of engineering disciplines, throughout the product life cycle.

Medical applications are typically subjected to a wide range of complex environmental and biological loading conditions.The variability of these conditions makes the physical testing of all possible scenarios both difficult and time-consuming. By using FEA and CFD multidisciplinary and multiphysics simulation technology, our engineers can study a greater number of real-world design behaviors with higher accuracy.

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte engineering team use advanced CAE software with special features for mixing the best of both FEA tools and CFD solvers: CFD codes such as MSC Cradle, Ansys Fluent, Siemens StarCCM+ and FEA Codes such as ABAQUS, Ansys, Nastran, LS-Dyna and MSC Actran for Acoustics and VibroAcoustics simulations.

Acoustics and Vibration Simulation

Finite Element Simulation of Heat Treatment

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

NVH & Acoustics for Hybrid & Electric Vehicles

FEA (Finite Element Analysis) & CFD Based Simulation of Blast, Explosion & Fire: Blast Resistance with Protection Against Ballistic Attacks

FEA Based Composite Material Design and Optimization: Fatigue, Fracture, Impact, Crash, Acoustics and Vibration with Abaqus, Ansys, COMSOL and LS-DYNA

Noise, Vibration & Harshness – NVH for Electric Motors

Electric Motors Cooling

Electromagnetic Multiphysics

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Audio Device Design: Acoustic simulation for Sound Quality Analysis in Consumer Electronic Devices

AeroAcoustics and VibroAcoustics in Automotive Industry

Finite Element Analysis of Durability and Fatigue Life

Aerodynamics Simulation

Casting: Finite Element and CFD Simulation Based Design

Additive Manufacturing and 3D Printing

Finite Element Welding Simulation: RSW, FSW, Arc, Electron and Laser Beam Welding

Seat Design: Finite Element and CFD Simulation for Static & Dynamic Comfort, Whiplash, Acoustic & Thermal Comfort, Crash Test

Hydrodynamics CFD simulation, Coupled with FEA for FSI Analysis of Marine and offshore structures

Metal Forming Simulation: FEA Based Design and Optimization

CFD and FEA in Civil Engineering: Seismic Design, Earthquake, Tunnel, Dam, Concrete Structures and Geotechnical Multiphysics Simulation

Marine and Shipbuilding Industry: Finite Element and CFD Based Simulation and Design

In Silico Medical & Biomedical Device Testing: Finite Element & CFD Simulation and Design, Considering FDA & ASME V&V 40

FEA and CFD Simulation for Aerospace Structures: Aerodynamics, Acoustics, Fatigue and Vibration, Thermal Analysis, Crash & Impact