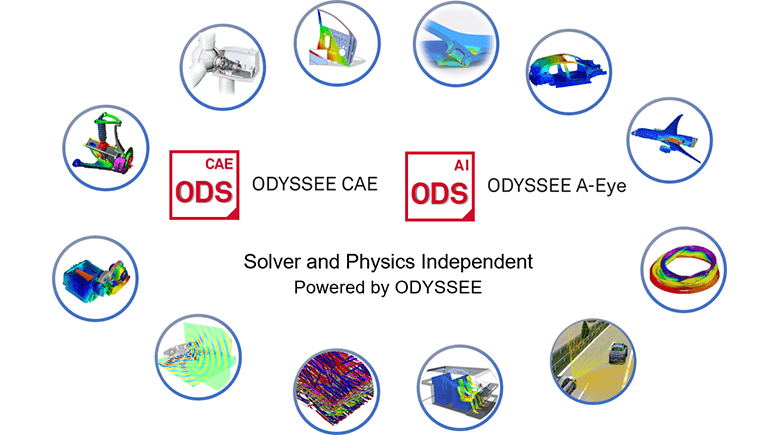

ODYSSEE: AI & Machine Learning for CFD, FEA, Statistics, Data Mining, Data Fusion, Optimization and Robustness

ODYSSEE CAE is a unique and powerful CAE-centric innovation platform that allows engineers to apply Machine Learning, Artificial Intelligence, Reduced Order Modelling (ROM) and Design Optimization to workflows. It allows you to benefit from modern data science technology by creating cost efficient digital twins through real-time predictive modeling and optimization for both CAE simulation data and physical test data.

ODYSSEE A-Eye

ODYSSEE A-Eye is a unique and powerful image-based machine learning solution that accelerates product design and development via real-time parametric simulation and optimization using machine learning and artificial intelligence (AI) solutions. ODYSSEE A-Eye allows you to create your own AI application based on image data, sensor data, scalars, labels, curves, and CAD data as inputs and then predicts responses using the known data of your system. This insight enables designers and production technicians to explore the design space more extensively and interactively and improve next-generation products without prohibitive computing cost or time.

ODYSSEE includes:

- Machine Learning & AI

- Statistics, Data Mining, Data Fusion

- Optimization and Robustness

- Process Discovery

- Image Recognition and Compression

ODYSSEE CAE

ODYSSEE CAE enhances your knowledge by answering complex engineering questions in real-time that would otherwise take hundreds of hours to simulate and analyze. With only a few previous CAE simulations, ODYSSEE predicts, optimizes, and robustly generates accurate results in real-time. ODYSSEE CAE produces full-time history outputs, including complete CAE analysis with detailed post-processing of results.

Enabling real-time prediction and optimization using image-based machine learning for any industry. ODYSSEE-A-Eye enables the creation of dedicated customizations for production/non-engineers using image-based prediction or based on CAD geometry (STEP).

Other Applications:

- Manufacturing Fault Monitoring (casting)

- Establishing cost indicators for tooling

- Fault characterization for quality control

- Constructability: Construction Risk, Uncertainty and Decision

- Diagnostic prediction of lung infections based on MRI images

- Remote Patient Monitoring augmented by real-time predictive model

- Flight Simulator (landing conditions)

- Satellite image selective compression and classification

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte offers a Virtual Engineering approach with FEA tools such as MSC Softwrae(Simufact, Digimat, Nastran, MSC APEX, Actran Acoustic solver), ABAQUS, Ansys, and LS-Dyna, encompassing the accurate prediction of in-service loads, the performance evaluation, and the integrity assessment including the influence of manufacturing the components.

Electromagnetic Multiphysics

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Seat Design: Finite Element and CFD Simulation for Static & Dynamic Comfort, Whiplash, Acoustic & Thermal Comfort, Crash Test

eVTOL (Electric Vertical Take-Off and Landing) & UAM (Urban Air Mobility)

FEA Based Composite Material Design and Optimization: MSC Marc, Abaqus, Ansys, Digimat and LS-DYNA

Additive Manufacturing and 3D Printing

Crash Test and Crashworthiness

Blast Resistance with Protection Against Ballistic Attacks

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Aerodynamics Simulation: Coupling CFD with MBD, FEA and 1D-System Simulation

Finite Element Simulation of Crash Test and Crashworthiness with LS-Dyna, Abaqus and PAM-CRASH

Simulation of Plasma Based Devices: Microwave Plasma and RF Plasma Analysis with Coupling Particle in Cell (PIC), MHD, CFD and FEA Solvers

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

CFD Simulation of Reacting Flows and Combustion

Finite Element Analysis of Durability and Fatigue Life

Multi-Phase Flows CFD Analysis

CFD and FEA in Civil Engineering: Seismic Design, Earthquake, Tunnel, Dam, Concrete Structures and Geotechnical Multiphysics Simulation

Marine and Shipbuilding Industry: Finite Element and CFD Based Simulation and Design

In Silico Medical & Biomedical Device Testing: Finite Element & CFD Simulation and Design, Considering FDA & ASME V&V 40

FEA and CFD Simulation for Aerospace Structures: Aerodynamics, Acoustics, Fatigue and Vibration, Thermal Analysis, Crash & Impact