Cabin Aerodynamics: CFD and FEA for The Passenger’s Thermal Comfort & Human Thermal Modeling, Aeroacoustic analysis of HVAC components, fans, blowers, air channels

FEA & CFD Based Simulation Design Analysis Virtual prototyping MultiObjective Optimization

The passenger’s thermal and acoustic comfort is an essential design-criterion for the air-conditioning and customization of a cabin. In industry, engineers conduct costly and time-consuming test series with specifically built cabin mock-ups to obtain some information about the expected passenger’s sensation of comfort already in the design process.

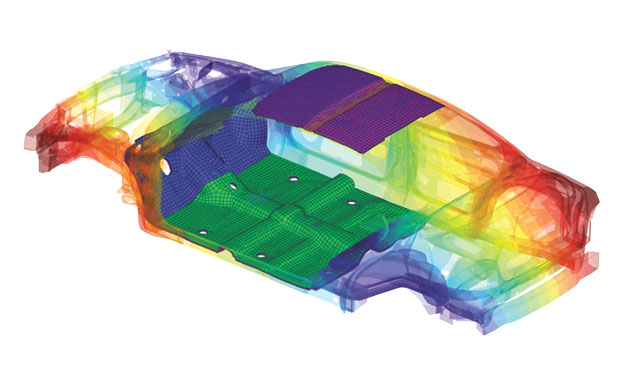

Aerodynamics, underhood thermal management, rotating equipment analysis of pumps, turbochargers, fans, etc. and aero- acoustics and vibro-acoustics consideration taken into account to capture real-world cabin condition of passengers and satisfy thermal comfort and noise level limitations.

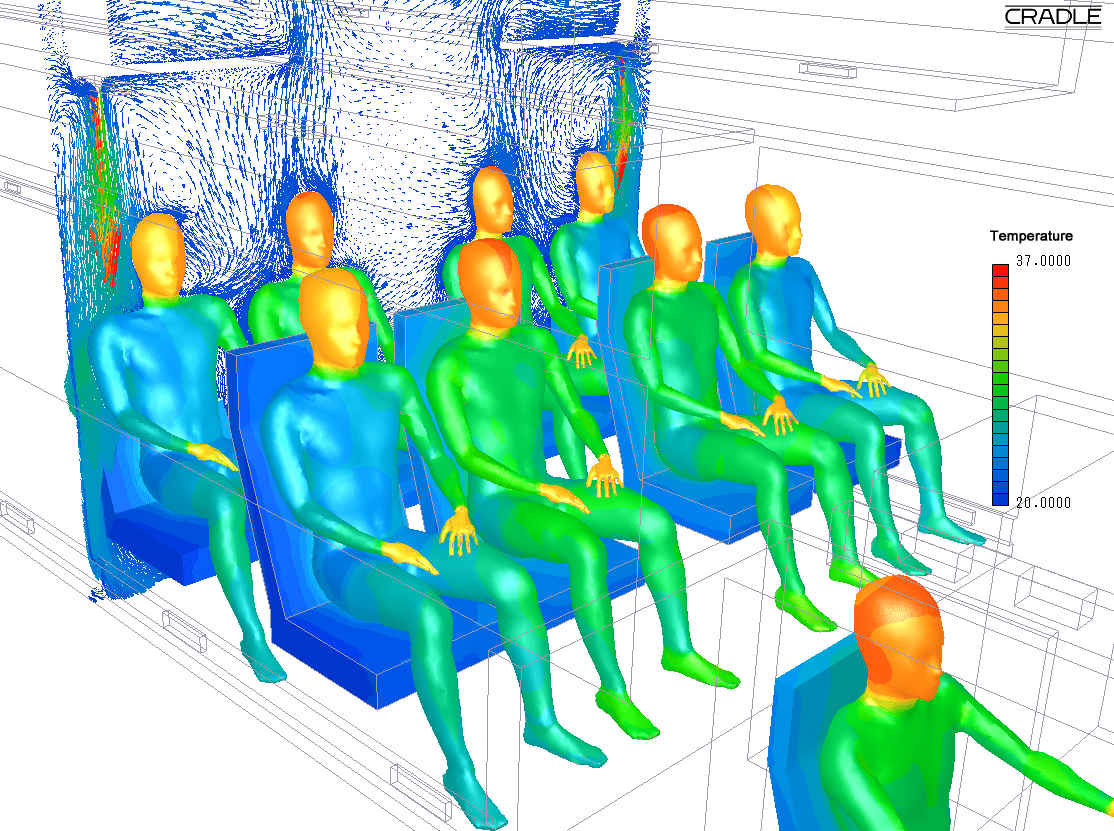

CFD Simulation can predict the passenger’s comfort by means of advanced software and to allow for an interactive layout of an optimized cabin. The CFD computations of the air flow in the cabin’s interior and the flow through cabin air outlets and noise level is optimized with the help flow and acoustic simulations to achieve design specifications.

Passenger Thermal Comfort

Our engineers use CFD tools in co-simulation with 1D system modeling softwares for develop and test control strategies, and study the impact of the system on overall vehicle thermal management, analyze thermal interactions between air conditioning loops or heat pump systems, the cooling system, additional heaters, and the cabin or vehicle interior, and control the cabin cool down or heating processes.

Enteknograte’s engineering team with deep knowledge in CFD and FEA and uses advanced softwares such as Siemens Star-ccm+, Ansys Fluent, Abaqus and Matlab Simulink to check the impact of exterior conditions and technological choices on the air temperature and humidity within the cabin, and assess human thermal comfort sensation and study and optimize the design of air conditioning and heat pump systems to ascertain that the system provides optimal passenger comfort in any innovative vehicle (VTOL, e-VTOL and UAM – Urban Air Mobility).

Human Thermal Modeling

Based on established models, the Human Thermal modeling is a state-of-the-art segmental model that operates within our thermal analysis software to provide a comprehensive simulation of human thermo-regulation under transient and asymmetrical environmental conditions. All thermo-regulatory responses are computed locally based on environmental conditions, clothing, body percentile, and activity level.

- Blood flow

- Respiration

- Shivering/sweating

- Conductive contact

Thermal Analysis Application

Human thermal applications include architectural analysis, passenger compartment design for vehicles and trains, firefighter safety equipment, and advanced materials for clothing systems.

- Protective clothing simulation

- HVAC optimization

- Window placement studies

- Localized building design

- Heated and cooled seats

- Human effectiveness and safety

Rotors Aerodynamic Simulation via Coupled FEA (MBD)/CFD Method: Aeroelastic Behavior Assessment

GREEN ENERGY: WIND TURBINE AND WIND FARM

Race Car Aerodynamic Simulation and Optimization via CFD

Drone Aerodynamic & Acoustic Simulation Based Design

Aerodynamics Simulation

Aerodynamic Noise Simulation

Multibody Dynamics & NVH (Noise, vibration, and harshness)

Electromagnetic Multiphysics

Acoustics and Vibration: FEA and CFD for AeroAcoustics, VibroAcoustics and NVH Analysis

Heat Transfer and Thermal Analysis: Fluid-Structure Interaction with Coupled CFD and Finite Element Based Simulation

Full Vehicle MultiBody Dynamics Simulation: Car Ride, Driveline, Engine and Tire MBD

Integrated Artificial Intelligence (AI) & Machine Learning - Deep Learning with CFD & FEA Simulation

Turbomachinery Generative Design & Optimization

Turbine, Pump & Compressor (Axial or Centrifugal)

WE WORK WITH YOU

We pride ourselves on empowering each client to overcome the challenges of their most demanding projects.

Enteknograte engineering team use advanced CAE software with special features for mixing the best of both FEA tools and CFD solvers: CFD codes such as MSC Cradle, Ansys Fluent, Siemens StarCCM+ and FEA Codes such as ABAQUS, Ansys, Nastran, LS-Dyna and MSC Actran for Acoustics and VibroAcoustics simulations.